Intelligent bucket elevator

A technology of intelligent bucket elevator and frame, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., and can solve problems such as undetectable, unable to convey dry or wet materials, bucket elevator belt slippage, etc. , to achieve the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

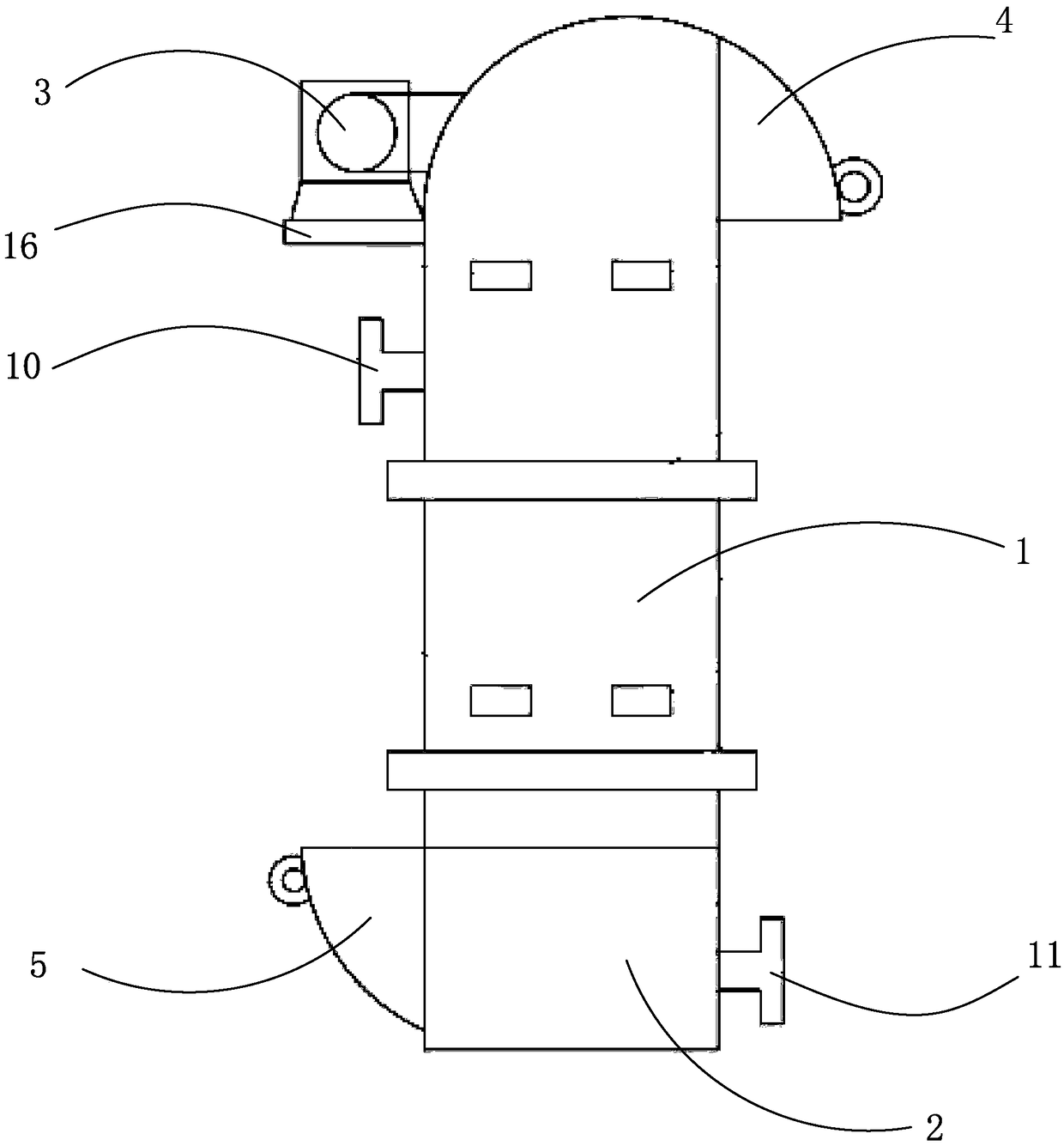

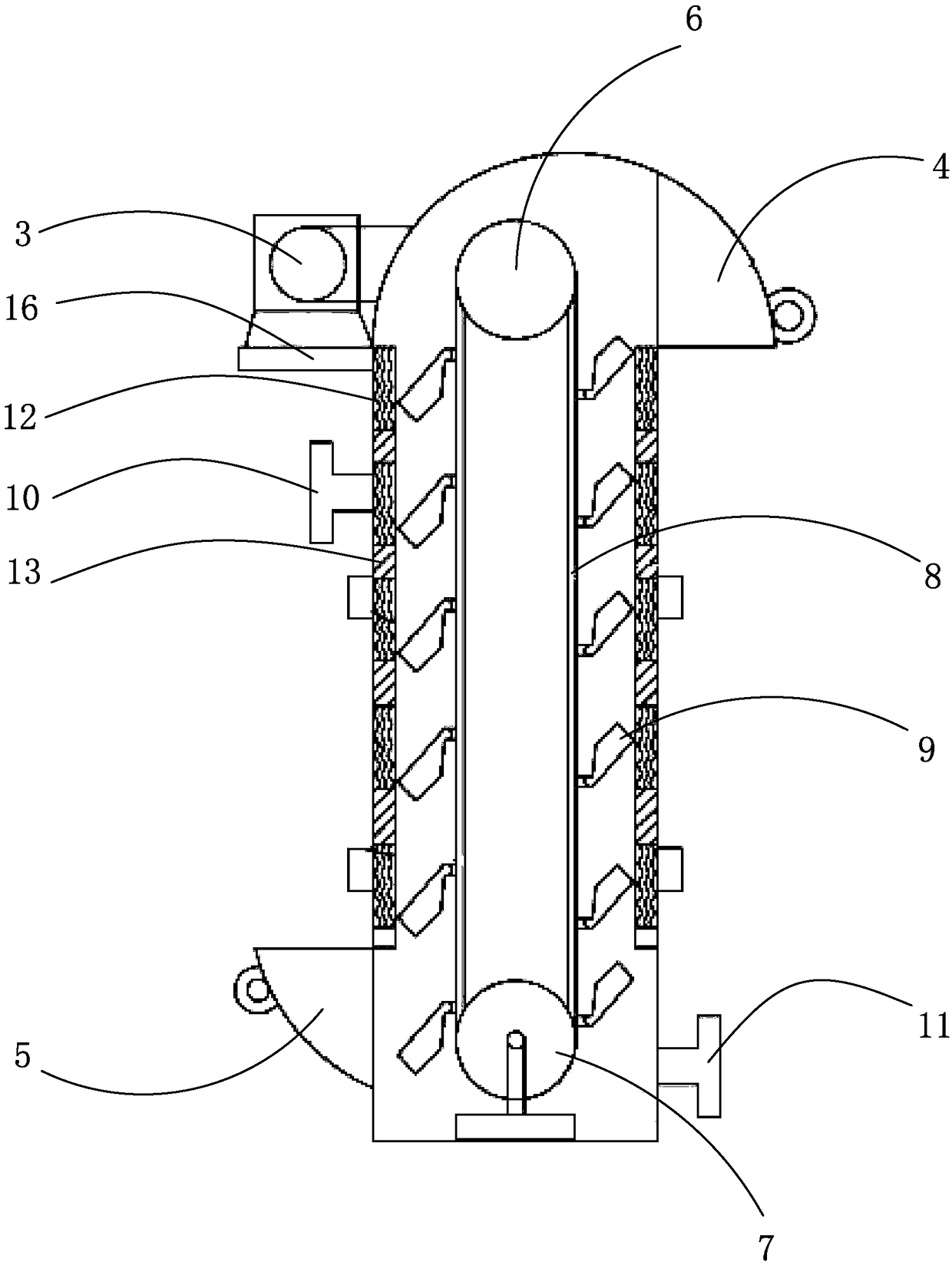

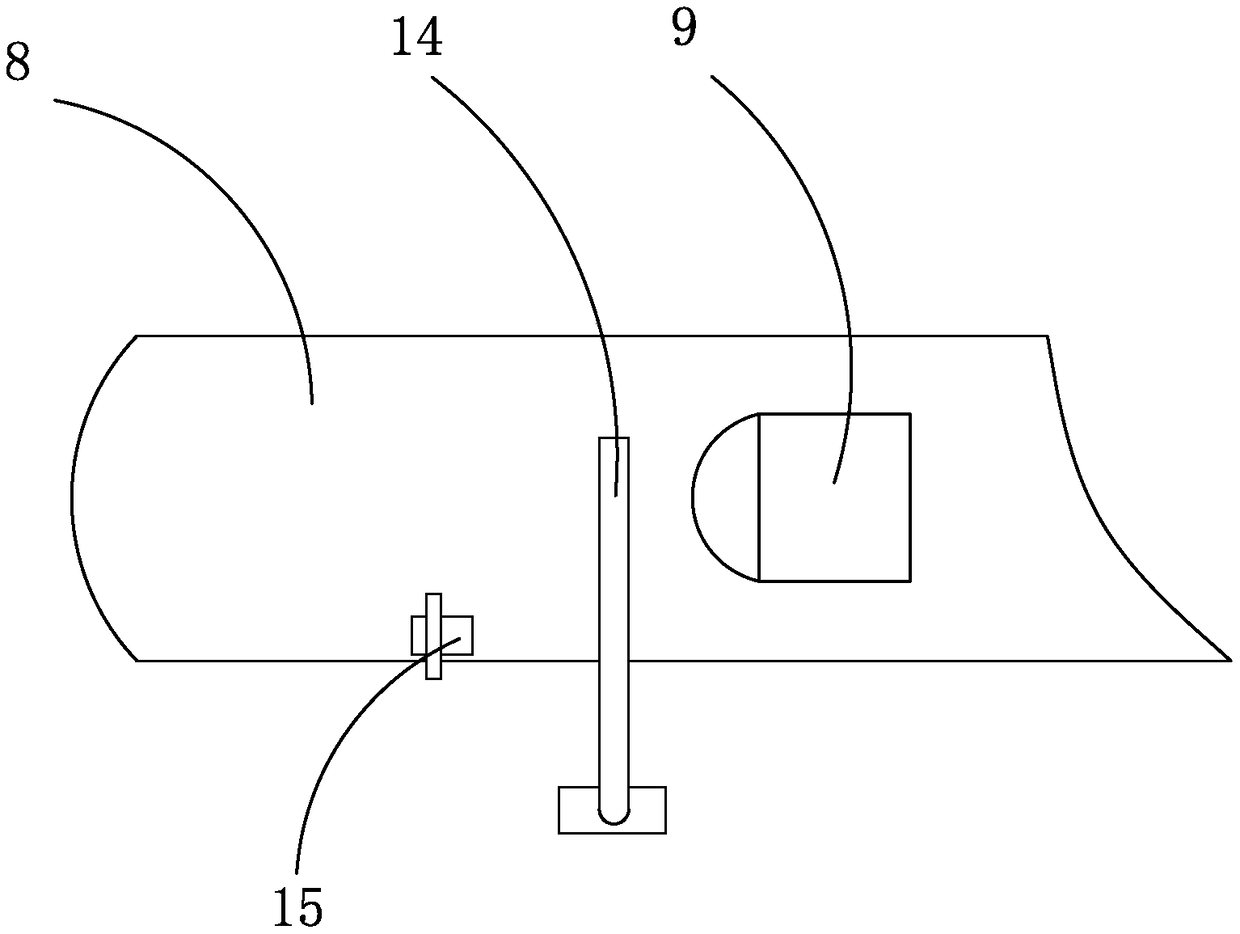

[0015] Such as Figure 1-Figure 3 As shown, a kind of intelligent bucket elevator provided by the present invention comprises a frame 1, a base 2 and a motor 3, the base 2 is fixedly connected to the bottom of the frame 1, the top of the frame 1 is provided with a discharge tray 4, and the base The side of 2 is provided with feed tray 5, and the interior of frame 1 is provided with driving wheel 6, driven wheel 7 and belt 8, and belt 8 transmission connects driving wheel 6 and driven wheel 7, and driving wheel 6 is positioned at the top of frame 1, And the driving wheel 6 is driven by the motor 3, the driven wheel 7 is located at the bottom of the frame 1, the belt is provided with a hopper 9, the frame 1 is provided with a temperature sensor and a controller electrically connected to it, and the two sides of the frame 1 are up and down. Each side is provided with a water inlet 10 and a water outlet 11, and a plurality of sprinklers 12 are arranged at intervals on the inner si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com