Rock soil slope anti-blocking forming water seepage drainage pipe

A technology for soil slopes and drainage pipes, which is applied in construction, infrastructure engineering, etc., can solve the problems of reducing the filtration area, reducing the impact force of drainage pipes, and affecting the safety of slopes, achieving large filtration area and high drainage efficiency , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

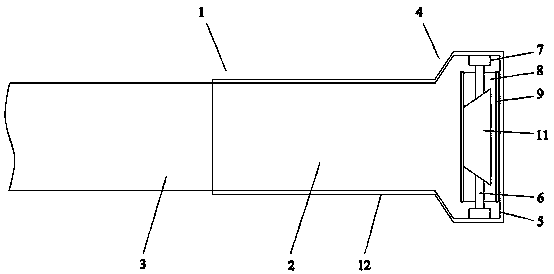

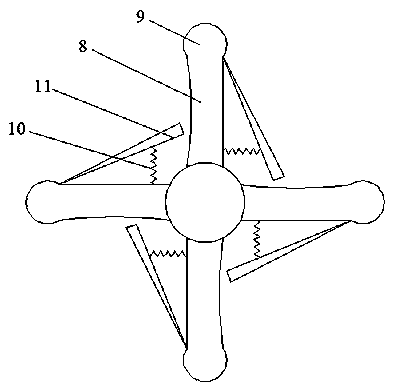

[0014] A rock-soil slope anti-blocking formed water seepage drainage pipe, comprising a drainage pipe body 1, the drainage pipe body 1 includes a water seepage section 2 placed inside the aquifer and a drainage section 3 placed outside the aquifer, the water seepage section 2 is provided with a seepage hole, and it is characterized in that: the end of the seepage section 2 is provided with an anti-blocking joint 4, and the anti-blocking joint 4 includes a joint pipe 5, a rotating shaft 6, a bearing 7, a stirring plate 8 and a matching Weight 9, one end of the joint pipe 5 communicates with the water seepage section 2 and is fixedly connected with the outer wall of the water seepage section 2, and the other end surface is provided with drainage holes at intervals, and the joint pipe 5 is provided with a rotating shaft 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com