Volute assembly for high speed electric direct drive centrifugal fan

A centrifugal fan and electric direct drive technology, which is applied to electric components, components of pumping devices for elastic fluids, electrical components, etc. The effect of improving the manufacturability, enhancing the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

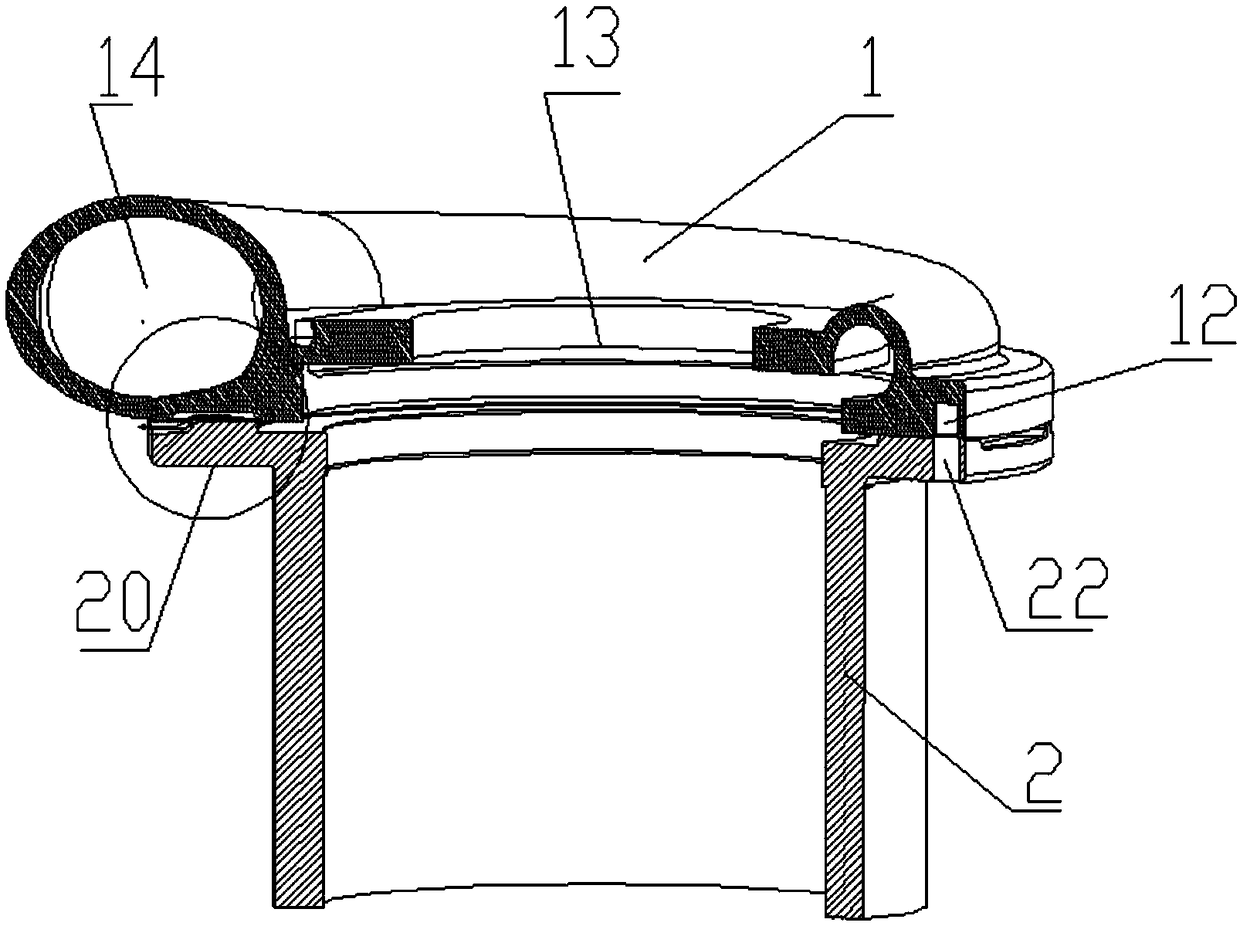

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

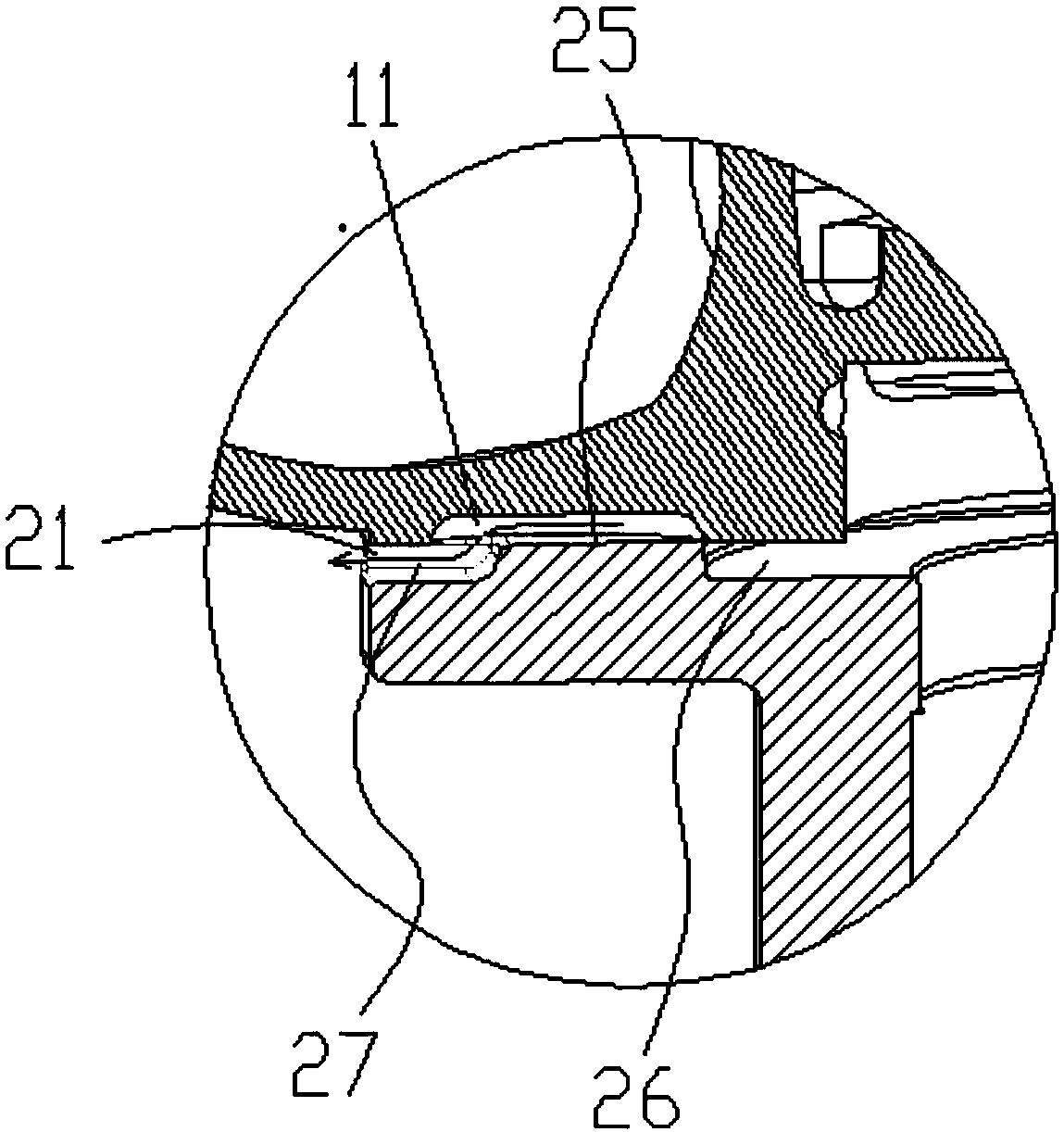

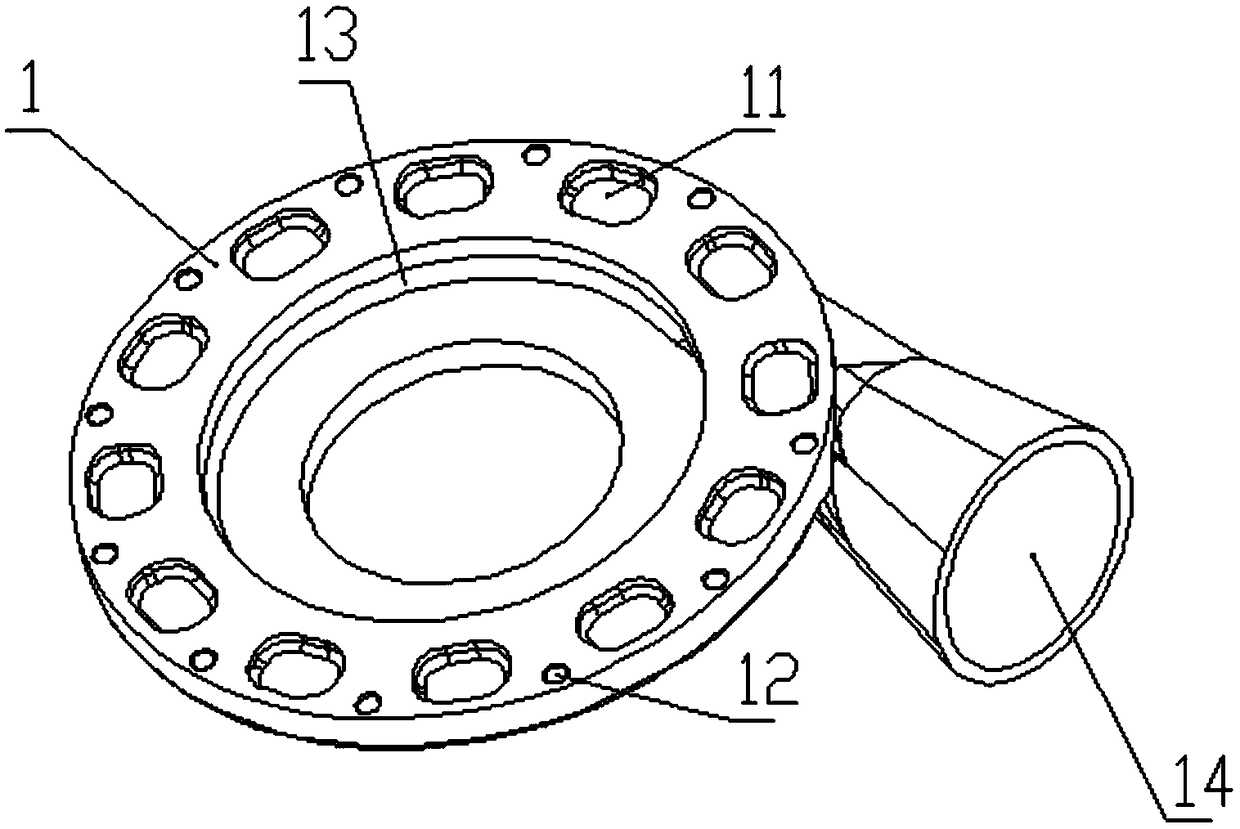

[0013] Such as Figure 1 to Figure 4 , the present invention is a volute assembly for a high-speed electric direct-drive centrifugal fan, comprising a volute 1 and a motor case 2, the volute 1 is provided with an air inlet 13 and an air exhaust port 14, and the bottom surface of the volute 1 It is a planar structure, and the upper port of the motor casing 2 extends outwards to form a platform-like installation plane 20 , and the bottom surface of the volute 1 and the installation plane 20 of the motor casing 2 are fixedly connected by bolts.

[0014] A number of waist-shaped grooves 11 are arranged on the bottom surface of the volute 1, and the waist-shaped grooves 11 are arranged along the circumferential direction of the air inlet 13, and a circular protrusion 25 is arranged on the installation plane 20 of the motor case 2. The raised part 25 is arranged coaxially w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com