Compression valve for automobile shock absorber

A technology for automobile shock absorbers and compression valves, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc. Breakthrough and other problems to achieve the effect of improving the shock absorption effect, increasing the service life and ensuring the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

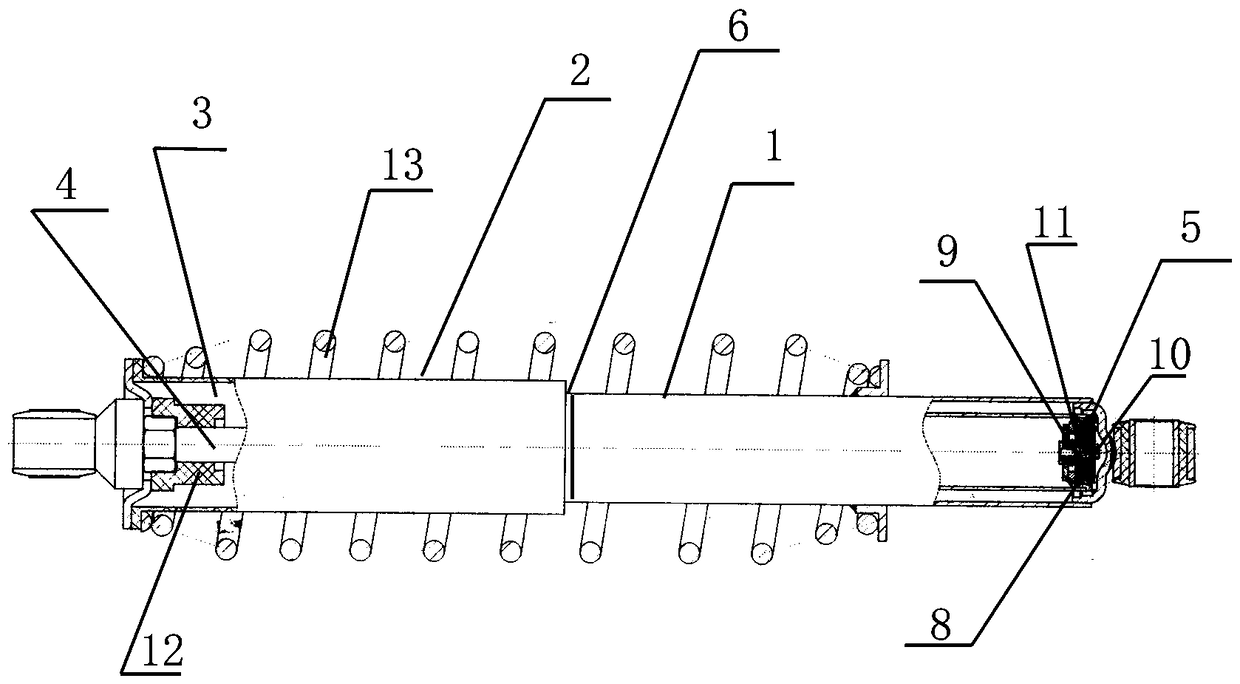

[0008] exist figure 1 Among them, the present invention provides an automobile shock absorber compression valve, which is provided with an inner tube 1 and an outer tube 2 in sequence from the inside to the outside, the outer tube 2 is inserted into the inner tube 1, and the inner cavity of the inner tube 1 is set as the working cavity 3 , the piston rod 4 is inserted into the working chamber 12 of the inner tube 1, a damping compression valve 5 is provided at one end of the piston rod 4, a sealing ring 12 is provided at the other end of the piston rod, and the outer parts of the inner tube 1 and the outer tube 2 There is a shock absorbing spring 13, and the joint of the outer pipe 2 and the inner pipe 1 is provided with a connecting liner 6, and the shock absorbing compression valve 5 includes a piston 8, an adjusting valve rod 9 and a connecting stud 10, the piston 8 is provided with a symmetrical flow hole 11, the flow hole 11 communicates with the working chamber 3 on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com