Gear maintenance hydraulic control system and gearbox

A technology of hydraulic control system and gearbox, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve problems such as immobility, hidden dangers, power failure of gearboxes, etc., to improve driving. Safety factor, avoidance of sudden changes in vehicle speed, and effect of maintaining vehicle speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

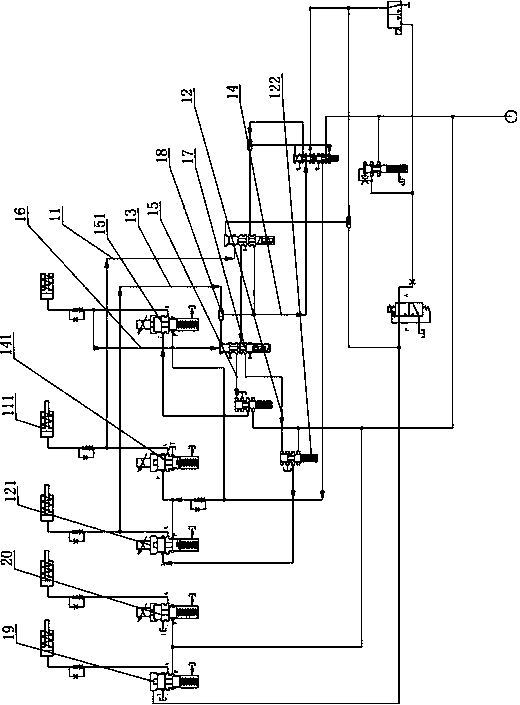

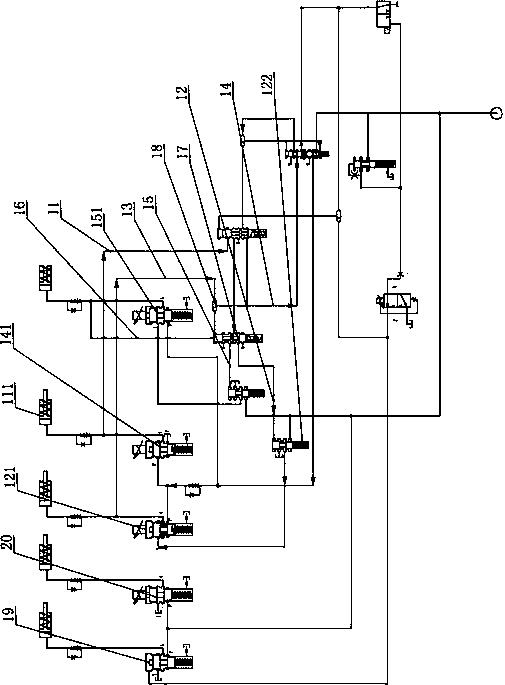

[0039] like Figure 1-Figure 3As shown, the gear holding hydraulic control system provided by the present invention includes a first oil passage 11, a second oil passage 12, a third oil passage 13, a fourth oil passage 14, a fifth oil passage 15 and a sixth oil passage 16 ; The first clutch 111 is provided on the first oil circuit 11, the first brake control valve 121 is provided on the second oil circuit 12, and the normal high solenoid valve 141 is provided on the fourth oil circuit 14, so The fifth oil passage 15 is provided with a second clutch control valve 151; the first oil passage 11 is connected with the second oil passage 12, one end of the third oil passage 13 is connected with the second oil passage 12, and the other end is connected with the second oil passage 12. The fourth oil passage 14 is connected, the fifth oil passage 15 is connected with the first oil passage 11, one end of the sixth oil passage 16 is connected with the fifth oil passage 15, and the other ...

Embodiment 2

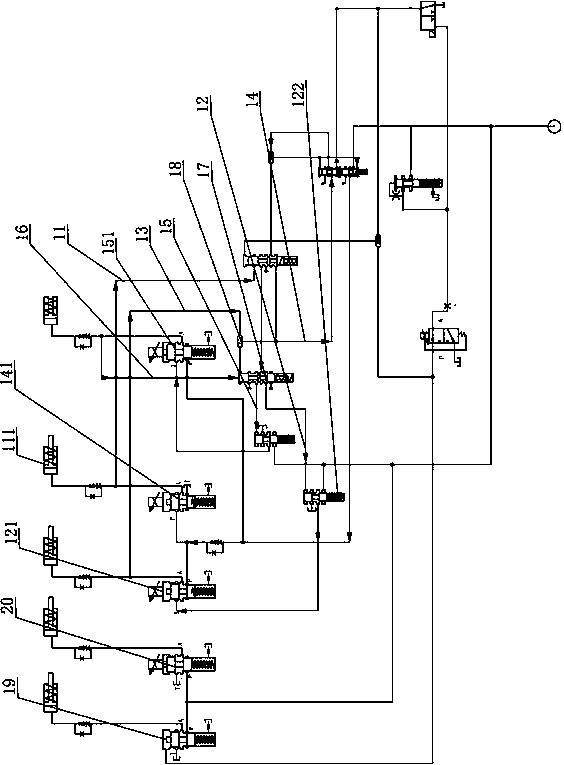

[0061] like Figure 4 As shown, in this embodiment, the difference between the gear holding hydraulic control system and the first embodiment is that it also includes the second brake control valve 19, the third brake control valve 20 and the fourth brake 21; the first clutch 111, the second brake The first brake, the second brake, the third brake, the fourth brake 21 and the second clutch form eight gears of the gearbox.

[0062] The first clutch 111, the first brake, the second brake, the third brake, the fourth brake 21 and the second clutch form the eight gears of the gearbox, and the cooperation between the fixed actuators forms the gearbox output gear to ensure that the vehicle runs in eight gears.

[0063]Further, the first brake can sequentially form the output of five gears in the first gear interval of the gearbox with the second brake, the fourth brake, the third brake, the first clutch 111, and the second clutch respectively; The second clutch can form three gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com