Driving mechanism of bevel gear transmission pipeline robot

A pipeline robot and driving mechanism technology, applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve the problems of slow speed and low efficiency, and achieve the effect of enhanced driving force and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

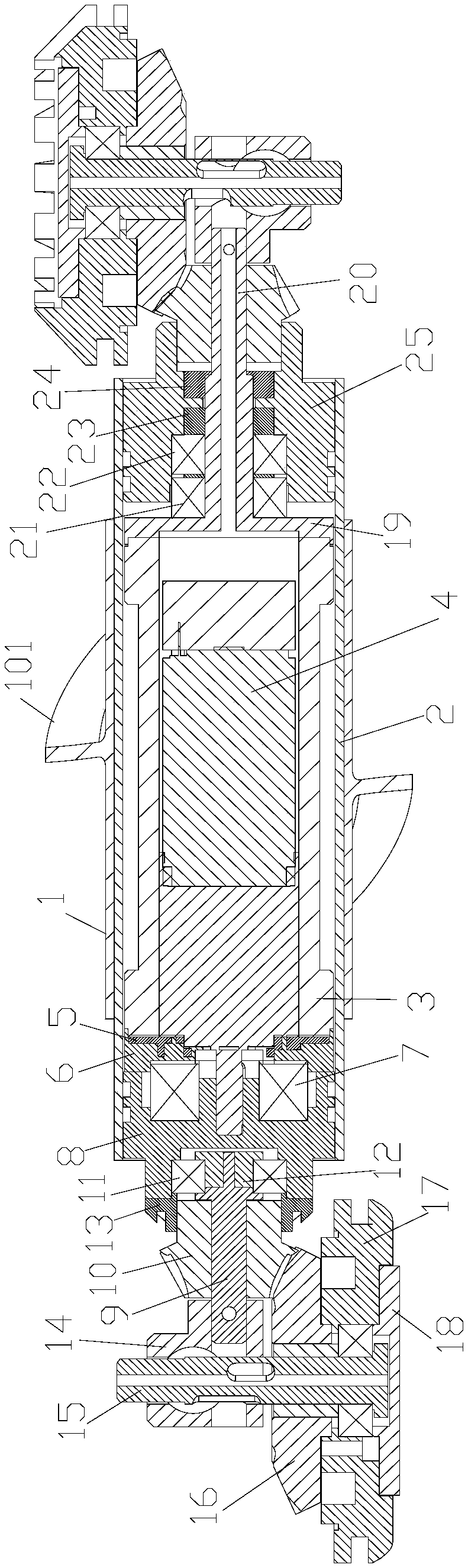

[0047] In order to make the purpose and technical solution of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

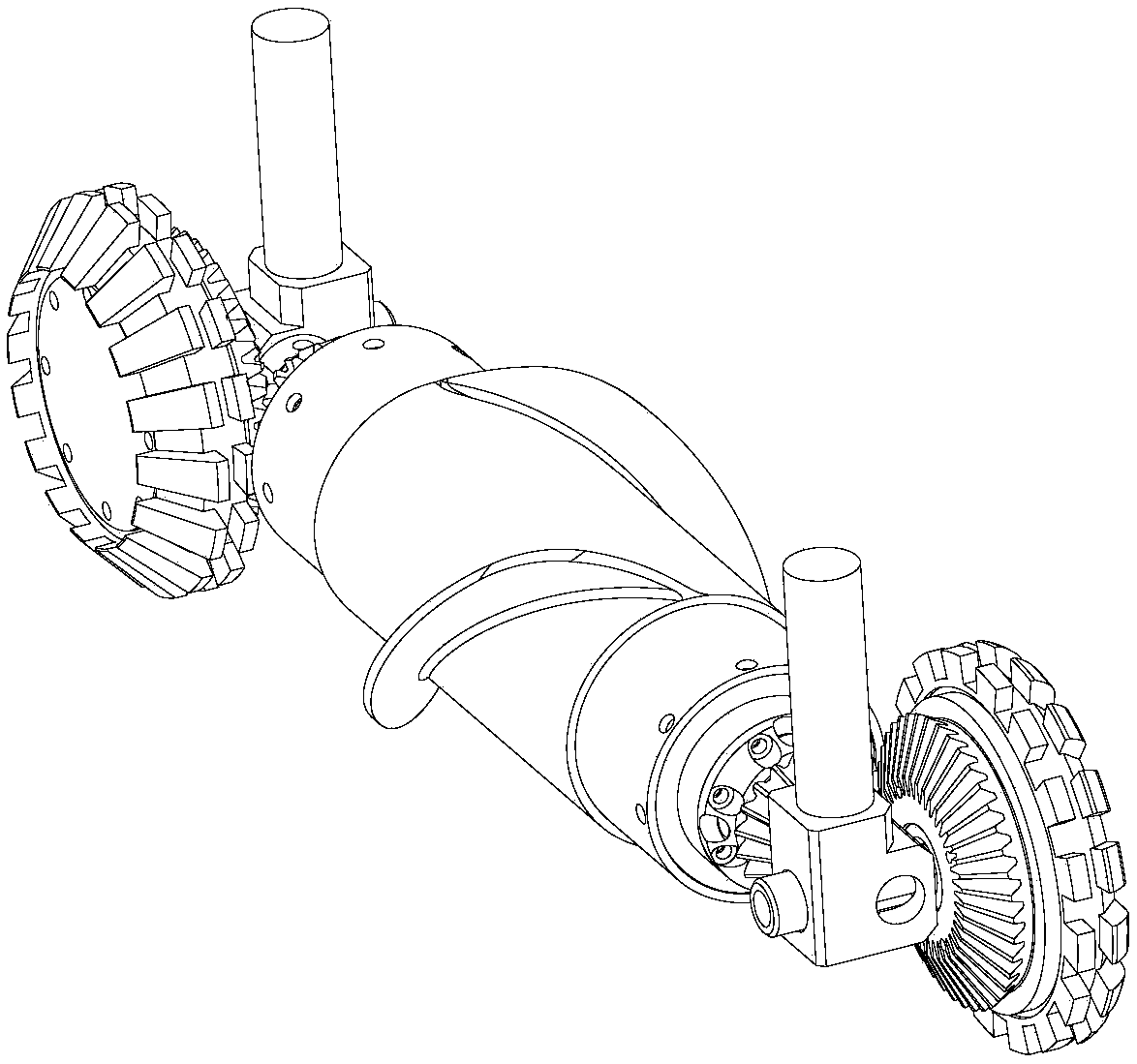

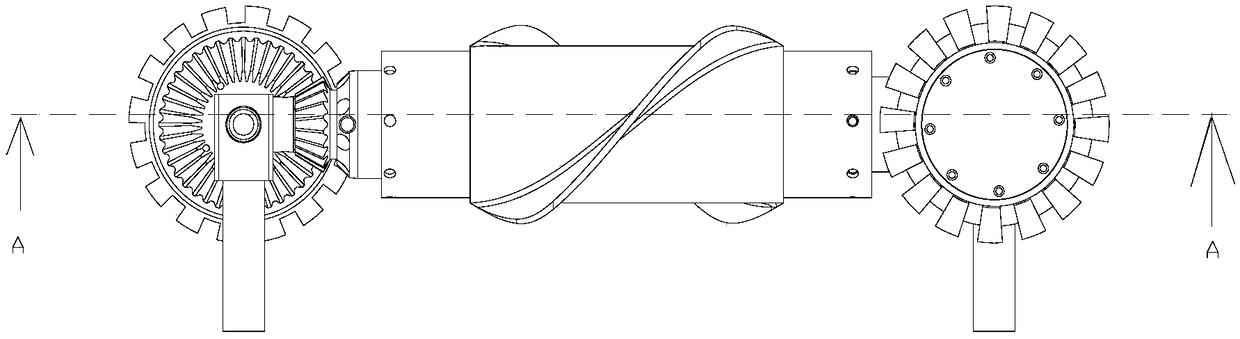

[0048] like Figure 1-12 As shown, a driving mechanism of a bevel gear transmission pipeline robot includes a driving roller and two driving rollers arranged at both ends of the driving roller.

[0049] Each driving roller comprises a first bevel gear 10, a second bevel gear 16, a first connecting piece 14 and a roller 17. One end of the first bevel gear 10 protrudes outward along the axial direction to form a boss 1001, and the center of the boss 1001 There is a first through hole 1002 through the first bevel gear along the axial direction; the first connecting piece 14 is fixedly connected with the first rotating shaft 15, and the second bevel gear 16 and the roller 17 are sleeved on the first rotating shaft 15, and the first b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com