Pipe shed construction method adopting three-arm drill jumbo

A technology of a rock drilling rig and a construction method, which is applied to earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of easy-to-collapse holes, poor hole-forming quality, and large environmental pollution, so as to prevent the collapse of the holes and improve the The effect of drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

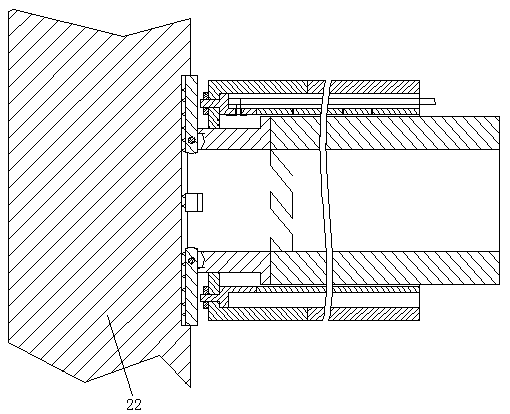

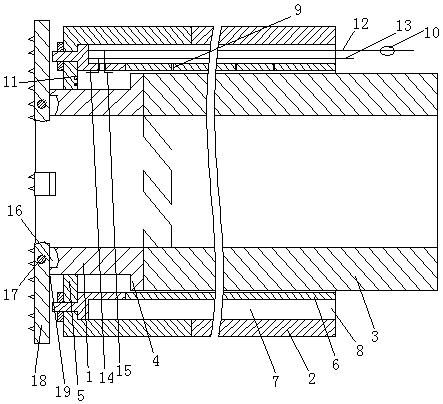

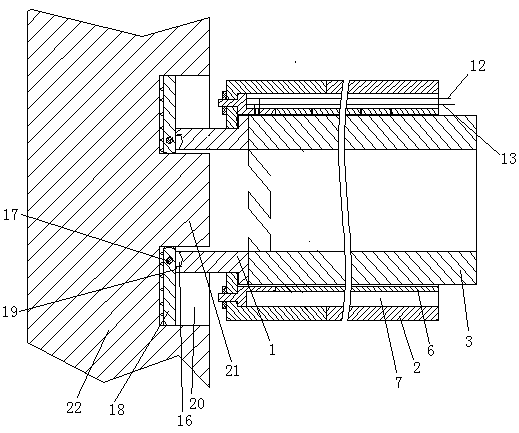

[0020] Example 1, see figure 1 with figure 2 , A three-arm rock drilling rig pipe shed construction method. The drilling mechanism is driven by the three-arm rock drilling rig to form holes in the mountain according to the following steps. The drilling mechanism includes an annular drill bit 1. The metal sheathed at the end of the annular brick The pipe 2 and the drill rod 3 of the pipe body structure connected with the tail end of the drill bit and penetrated in the metal pipe. The tail end of the ring bit is provided with an outer flange 4. The front end of the metal tube is provided with an inner flange 5 capable of abutting on the outer flange. An inner tube 6 is also passed through the metal tube. A shaped cavity 7 between the inner tube, the inner flange and the metal tube. The end of the cavity away from the drill bit is fully opened to form an opening 8. The inner tube is connected with the inner flange. The inner tube is provided with a number of water seepage hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com