LED point-source lamp

A technology for spot lights and lamps, applied in the direction of light source, electric light source, light source fixation, etc., can solve the problems of high assembly cost, poor waterproof, yellowing resistance, etc., to achieve convenient production and assembly, easy maintenance, replacement, extension The effect of lamp life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

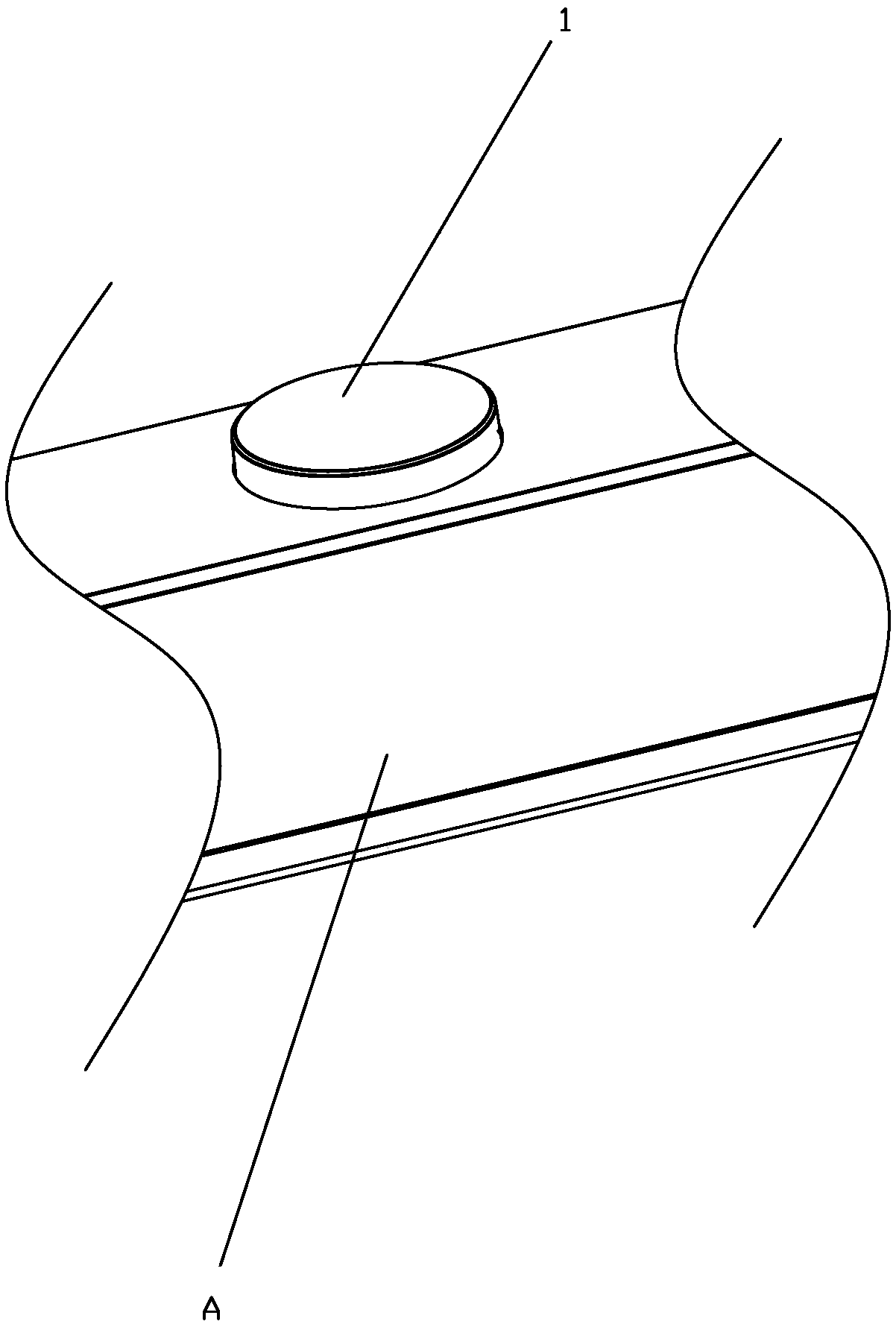

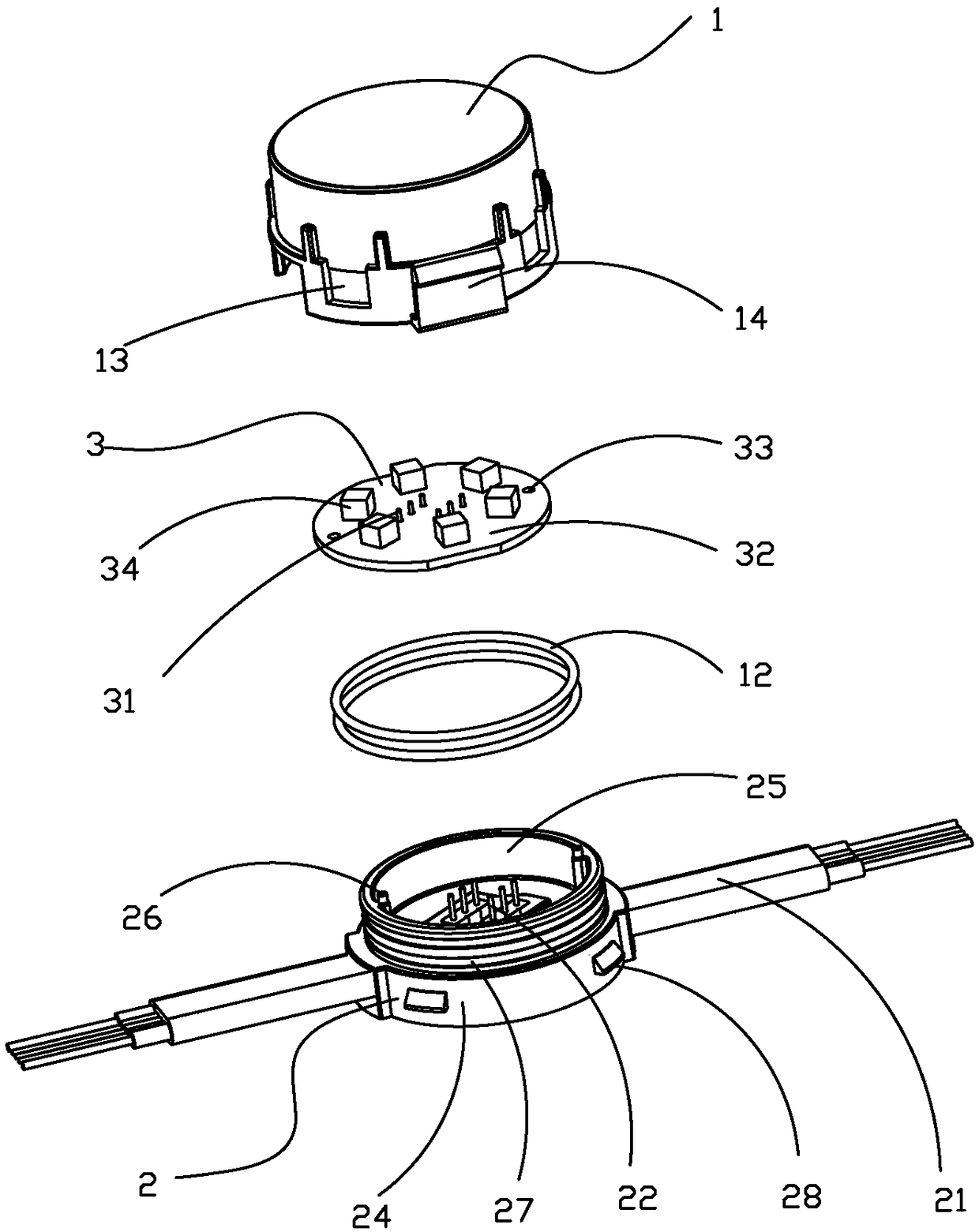

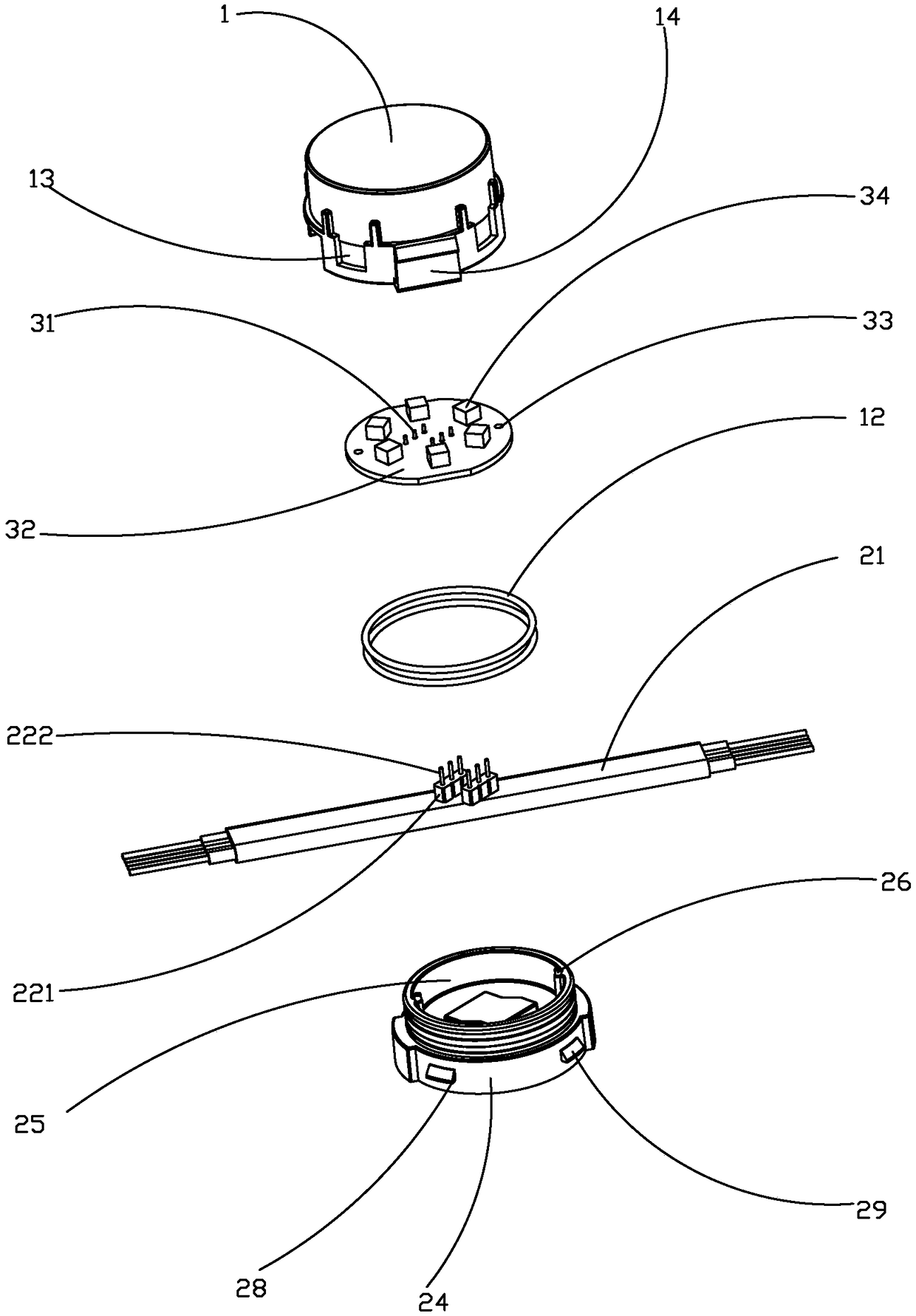

[0025] like Figure 1-5 The shown LED spotlight includes a lamp shell 1 that is clamped on the decorative aluminum groove A, and a lamp base 2 is provided inside the lamp shell 1, and the sealed space between the lamp shell 1 and the lamp base 2 is A light source board 3 is provided, and the lamp base 2 is provided with a wire 21 and a power supply male pin 22 conducting with the wire 21. slot 31 , when the male power supply pin 22 is inserted into the female power supply slot 31 , the circuit between the wire 21 and the light source board 3 is conducted. The spot light is stuck in the hole on the decorative aluminum slot, and the aluminum slot can be punched arbitrarily to expose the lamp shell of the spot light, while the power line is hidden inside the decorative aluminum slot, the exterior of the decorative aluminum slot is beautiful and tidy, and the lamp The shell covers the lamp base, and a closed space is set between the lamp shell and the lamp base to accommodate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com