Substrate clamp for film stress test

A technology of film stress and substrate clamping, which is applied in the measurement of the change force of optical properties of the material when it is stressed, can solve the problems of poor coating effect, large influence on the coating surface, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

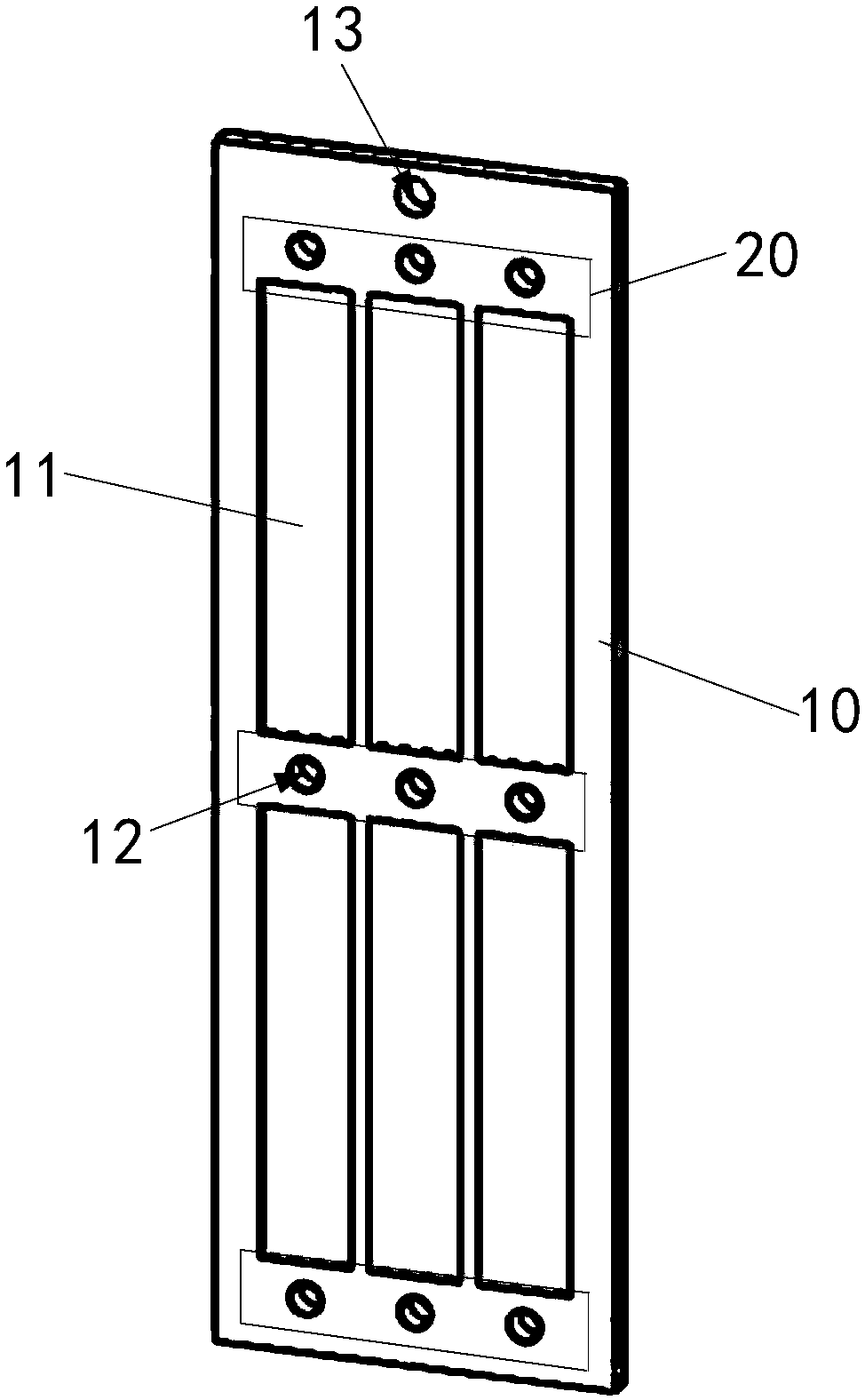

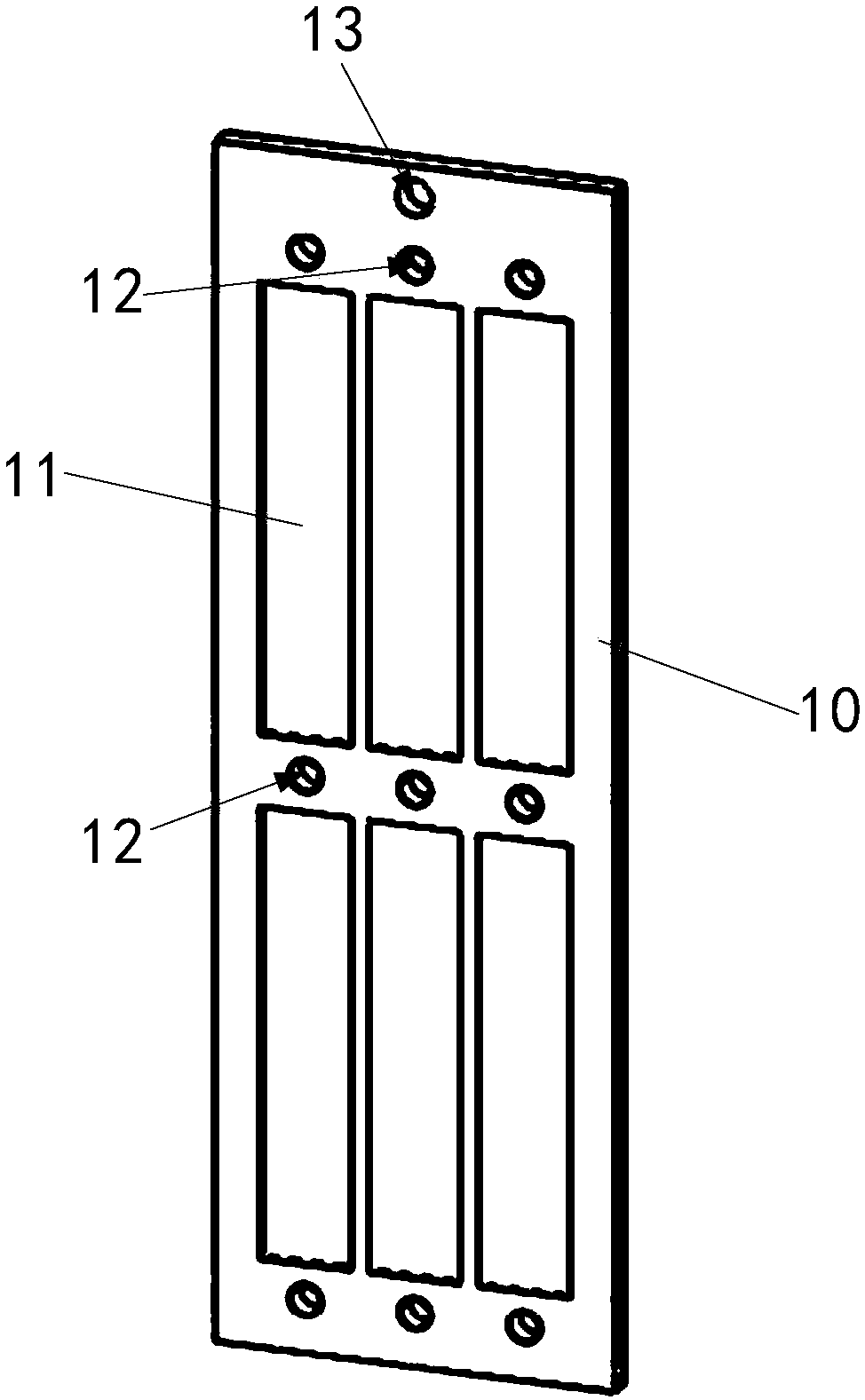

[0037] Such as Figure 1-4 As shown, the substrate fixture for film stress testing provided in this embodiment includes a base 10 and a clip 20;

[0038] The base 10 is provided with a plurality of clamping parts, and two ends of each clamping part are respectively provided with clamping holes 12;

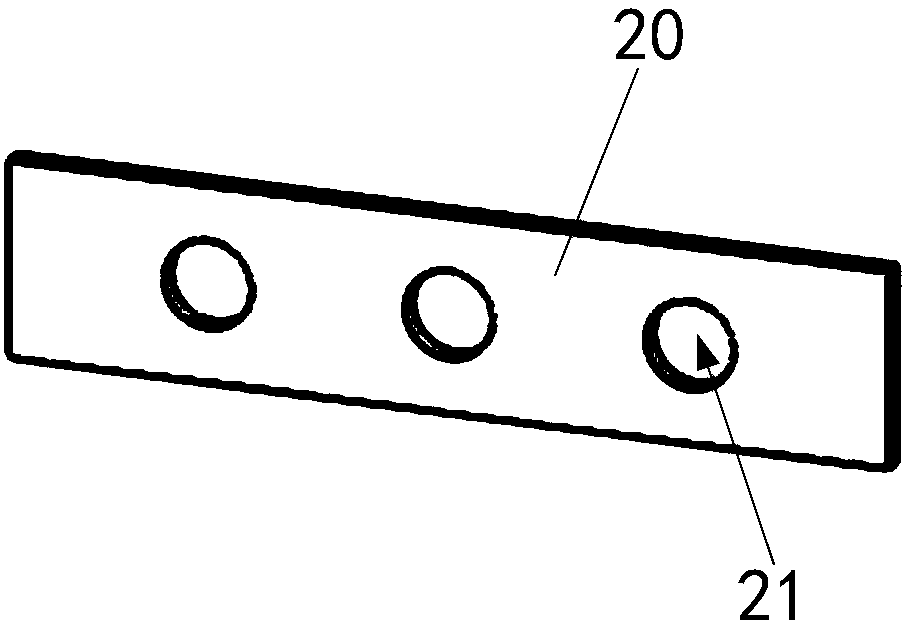

[0039] The clip 20 is provided with a connecting hole 21, and the connector passes through the connecting hole 21 and the clamping hole 12 in turn, so that the sample 30 to be coated is fixed on the clamping part, and one end of the base 10 Hanging holes 13 are also provided.

[0040] In the substrate fixture for film stress testing provided by the embodiment of the present invention, the base 10 is provided with a plurality of clamping parts, the two ends of each clamping part are respectively provided with clamping holes 12, and the clip 20 is provided with The connecting hole 21, the connecting piece passes through the connecting hole 21 and the clamping hole 12 in turn, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com