Accelerated test method for simulating atmospheric corrosion of aluminum alloy in coastal ventilation room

A technique for atmospheric corrosion and accelerated testing, used in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

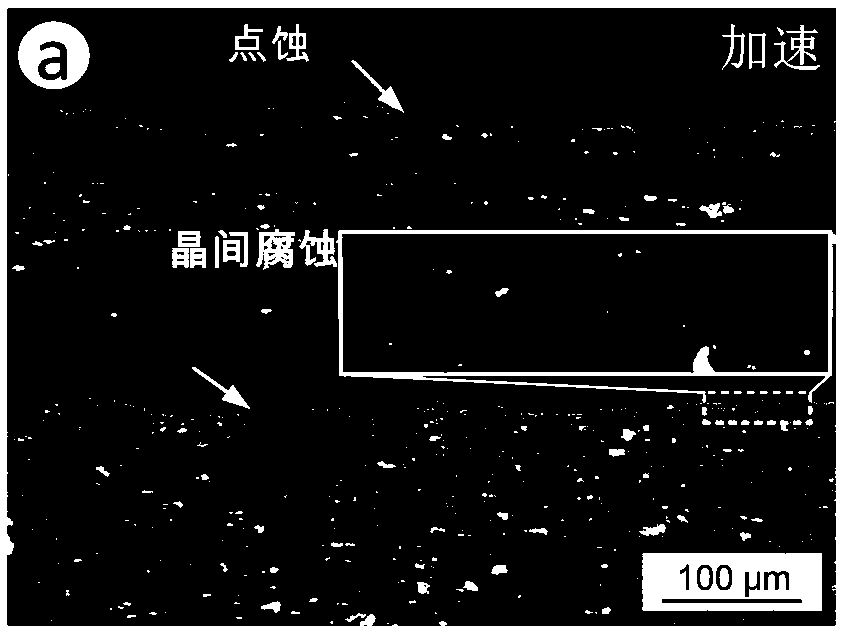

[0040] In order to make the above-mentioned technical solution of the present invention more obvious and easy to understand, the present invention will be described in detail below by taking the example of simulating the atmospheric corrosion of aluminum alloy in a ventilation room in the coastal environment of Wanning, Hainan, China.

[0041] 1. Making test pieces

[0042] The material of the test piece is 2A12-T4 aluminum alloy, and the material composition is shown in Table 1.

[0043] Table 1 Chemical composition of test piece materials

[0044]

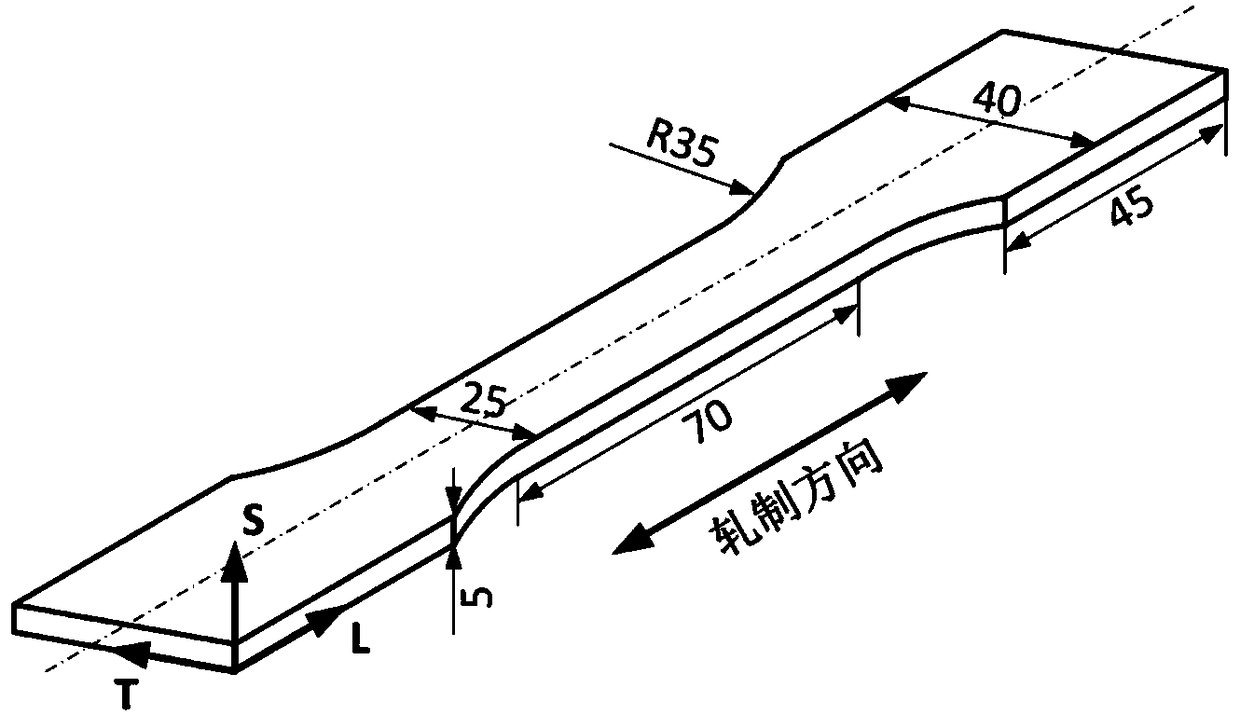

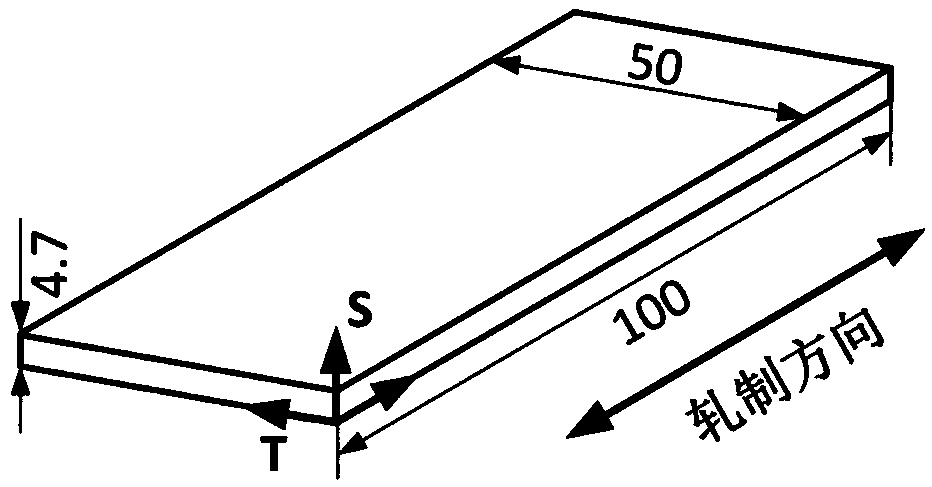

[0045] The test pieces and the accelerated corrosion test pieces exposed in the ventilation room in the coastal environment of Wanning, Hainan Province are dog-bone-shaped and flat-plate-shaped respectively, as shown in Figure 1(a) and Figure 1(b), the surfaces of these two test pieces are not Contains an aluminum clad layer.

[0046] For the test pieces exposed in the ventilated room in the coastal environment of Wanning, H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com