A Dynamic Process Monitoring Method Based on Dynamic Orthogonal Component Analysis

A dynamic process and component analysis technology, applied in the direction of program control, electrical program control, comprehensive factory control, etc., can solve problems such as sequence correlation considerations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific examples of implementation.

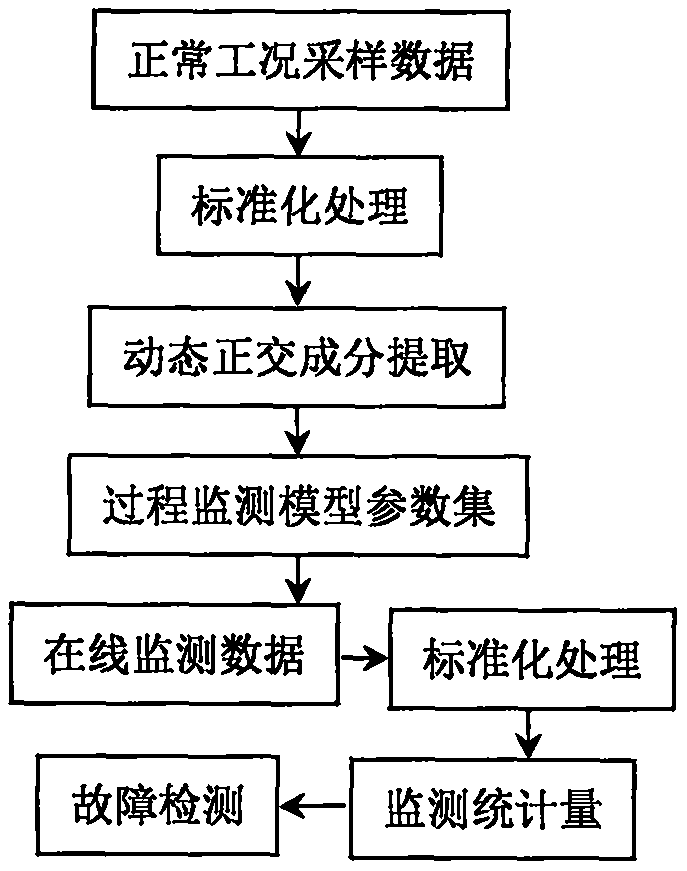

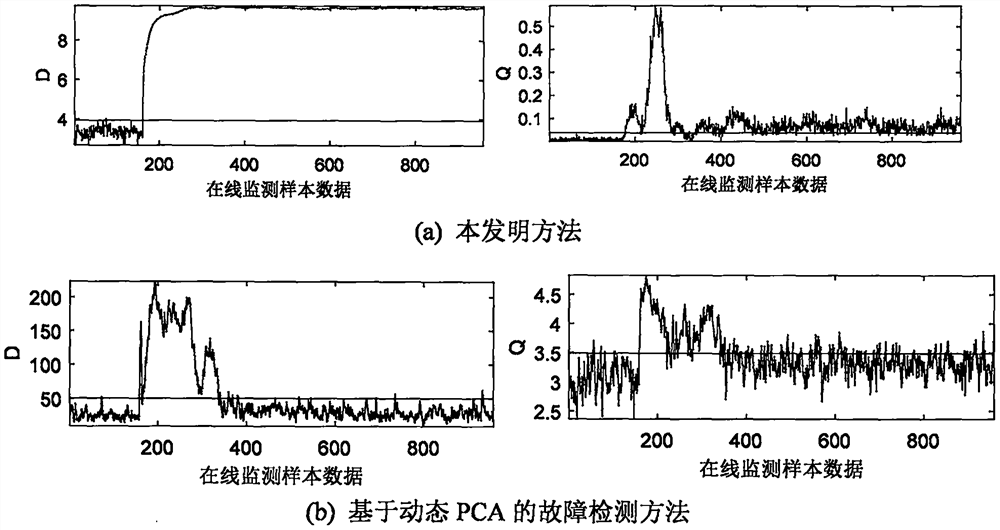

[0034] Such as figure 1 As shown, the present invention discloses a dynamic process monitoring method based on dynamic orthogonal component analysis. The specific implementation process of the method of the present invention and its advantages over the existing methods will be described below in conjunction with an example of a specific industrial process.

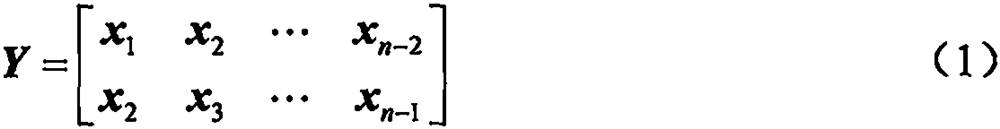

[0035] The application object is from Tennessee-Eastman (TE) chemical process experiment, and the prototype is an actual process flow of Eastman chemical production workshop. Currently, the TE process has been widely used in fault detection research as a standard experimental platform due to its complexity. The whole TE process includes 22 measured variables, 12 manipulated variables, and 19 component measured variables. The collected data are divided into 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com