Steel sheet

一种钢板、化学组成的技术,应用在高强度钢板领域,能够解决兼顾强度成型性的提高困难、无法得到充分的特性、成型性扩孔性困难等问题,达到优异外观、优异强度及成型性、抑制表面缺陷的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

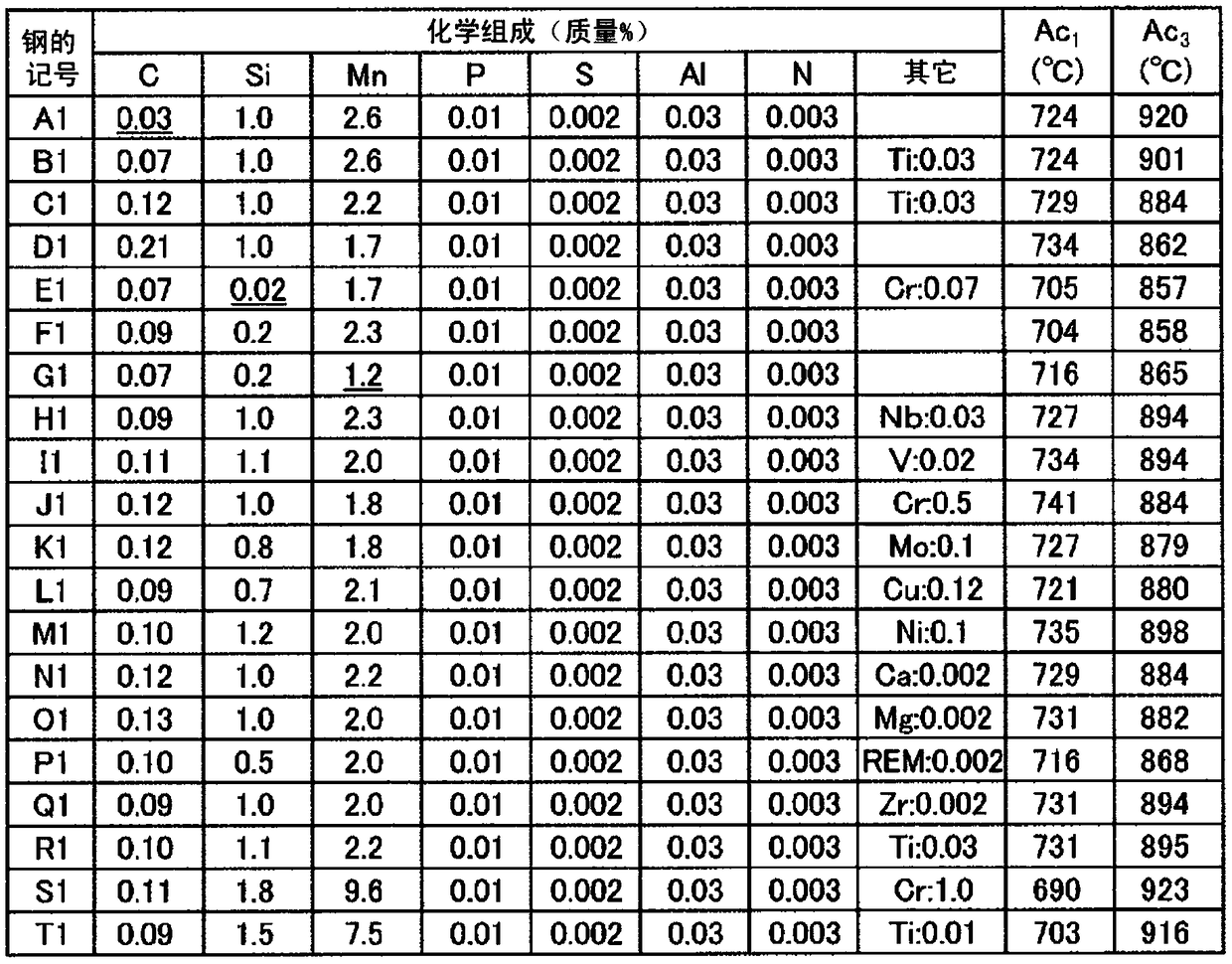

[0153] Next, examples of the present invention will be described. The conditions in the examples are an example of conditions adopted for confirming the feasibility and effects of the present invention, and the present invention is not limited to the examples of conditions. The present invention can adopt various conditions as long as the object of the present invention is achieved without departing from the gist of the present invention.

no. 1 Embodiment

[0155] Slabs having the chemical compositions shown in Table 1 were produced, and after heating the slabs to 1250° C. for 1 hour, multiaxial compression processing was performed under the conditions shown in Table 2. Next, the slab was reheated to 1250° C., and rough rolled to obtain a rough rolled sheet. Thereafter, the rough-rolled steel sheet was reheated at 1250° C. for 1 hour, and finish-rolled under the conditions shown in Table 2 to obtain a hot-rolled steel sheet. It should be noted that, in this experiment, in the arrangement of the experimental equipment, since the temperature of the slab had to be lowered, reheating was carried out. heating. In the finish rolling, the first rolling was performed in 4 steps, the second rolling was performed in 2 steps, and after coiling, it was kept at the coiling temperature for 1 hour. Thereafter, the hot-rolled steel sheets were pickled, and cold-rolled at the rolling reductions shown in Table 2 to obtain cold-rolled steel sheet...

no. 2 Embodiment

[0171] Slabs having the chemical compositions shown in Table 5 were produced, and after heating the slabs to 1250° C. for 1 hour, multiaxial compression processing was performed under the conditions shown in Table 6. Next, the slab was reheated to 1250° C. and rough-rolled to obtain a rough-rolled sheet. Thereafter, the rough-rolled steel sheet was reheated at 1250° C. for 1 hour, and finish-rolled under the conditions shown in Table 6 to obtain a hot-rolled steel sheet. It should be noted that, in this experiment, in the arrangement of the experimental equipment, since the temperature of the slab had to be lowered, reheating was carried out. heating. In the finish rolling, the first rolling was performed in 4 steps, the second rolling was performed in 2 steps, and after coiling, it was kept at the coiling temperature for 1 hour. Thereafter, the hot-rolled steel sheets were pickled, and cold-rolled at the rolling reductions shown in Table 6 to obtain cold-rolled steel sheets...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| area ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com