Electric conduction type shoe film wearing device

A wearable device, power-on technology, applied in clothing, applications, hangers, etc., can solve the problems of cumbersome operation steps, complex action mechanism, difficult operation, etc., and achieve the effect of high precision, low precision, and pollution avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

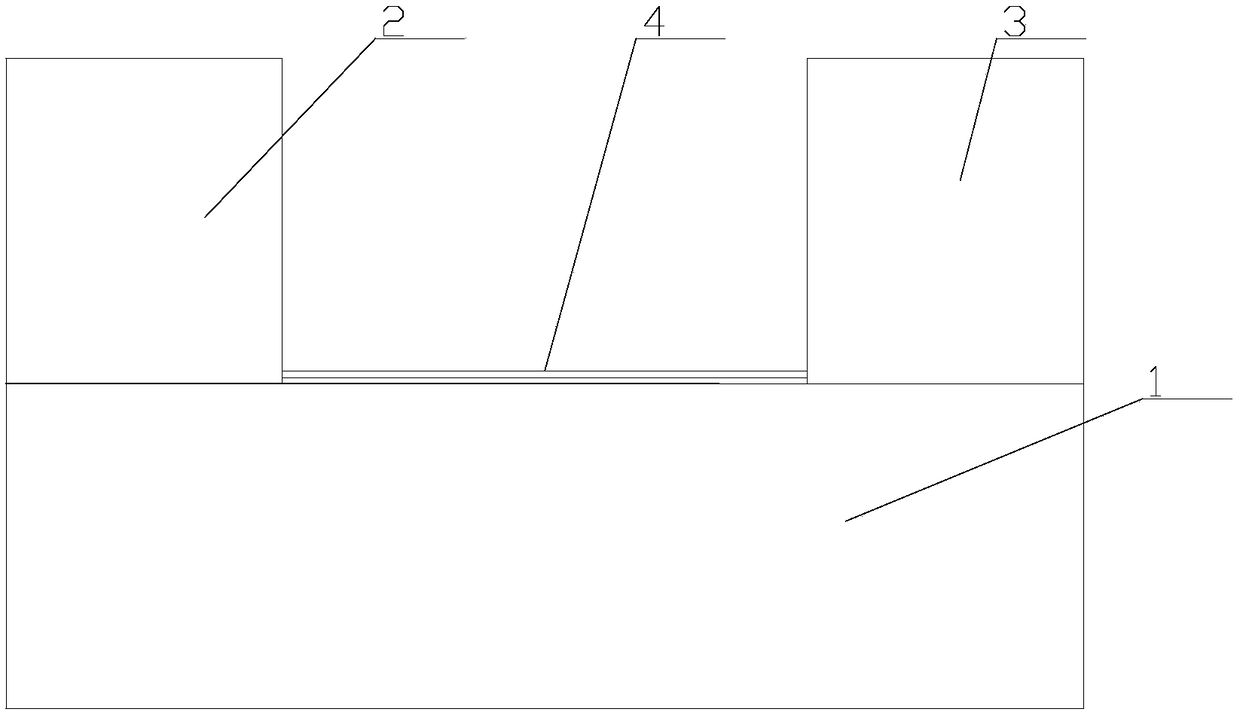

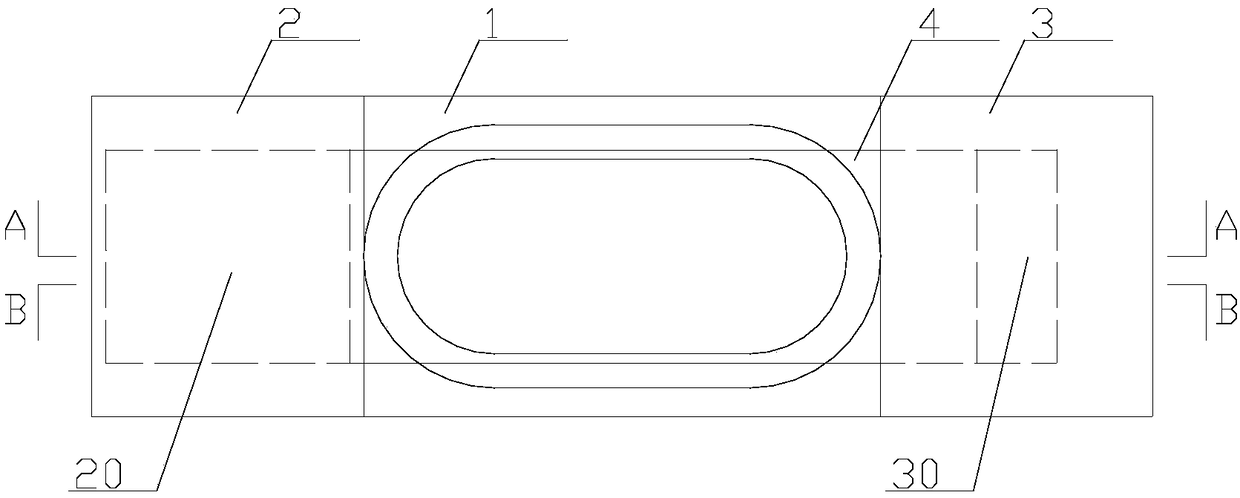

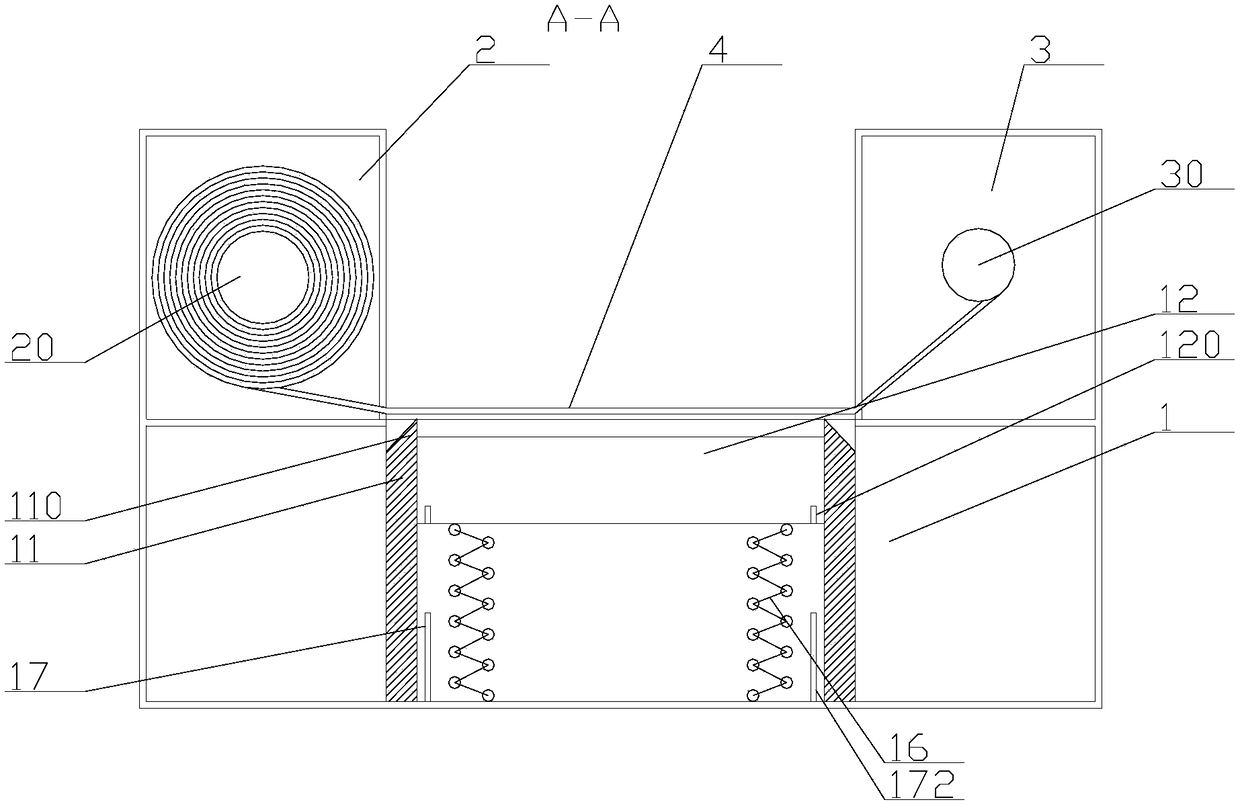

[0015] The present invention as Figure 1-4 As shown, it includes a base 1, a new material bin 2, a waste material bin 3 and an adhesive film 4, and the new material bin 2 and the waste material bin 3 are respectively fixedly connected to both sides of the top surface of the base 1, and the new material bin A new material winding roller 20 is hinged in 2, a waste material winding roller 30 is hinged in the waste bin 3, one side of the adhesive film 4 is fixedly connected to the new material winding roller 20, and the new material winding roller 20 is wound around it, The other side of described adhesive film 4 is fixedly connected on the scrap winding roller 30;

[0016] The base 1 is provided with a guide ring 11, a supporting plate 12, at least one support spring 16 and a heating assembly 17. The guide ring 11 is fixedly connected in the base 1 and is located in the new bin 2 and the waste bin 3. Between, the top of described guide ring 11 is open-shaped, and the inner edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com