A logistics sorting device

A sorting device and logistics technology, which is applied in sorting and other directions, can solve the problems of the bottom surface of the goods being worn or worn out, and the goods are damaged, and achieve the effects of quality assurance, small friction, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

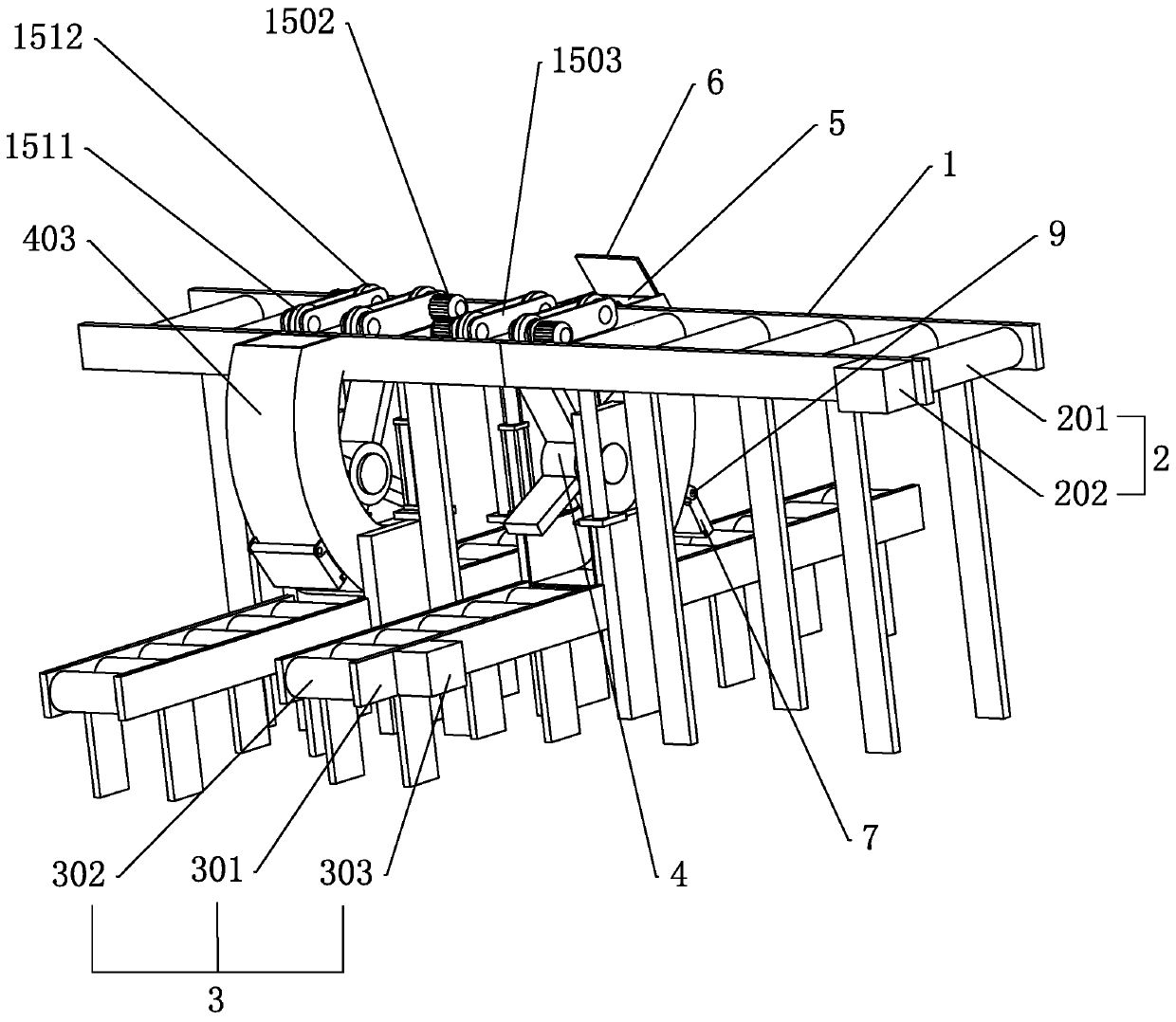

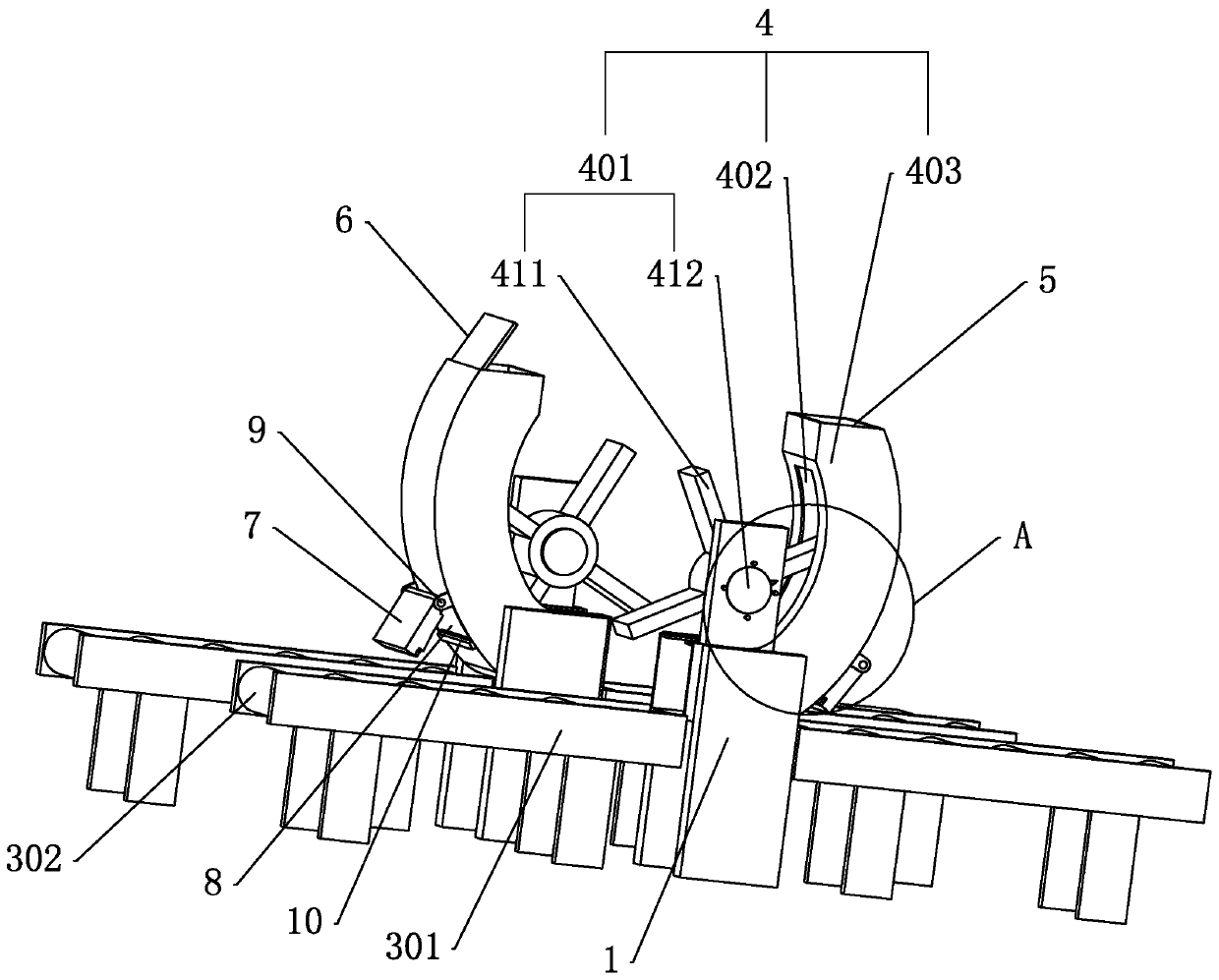

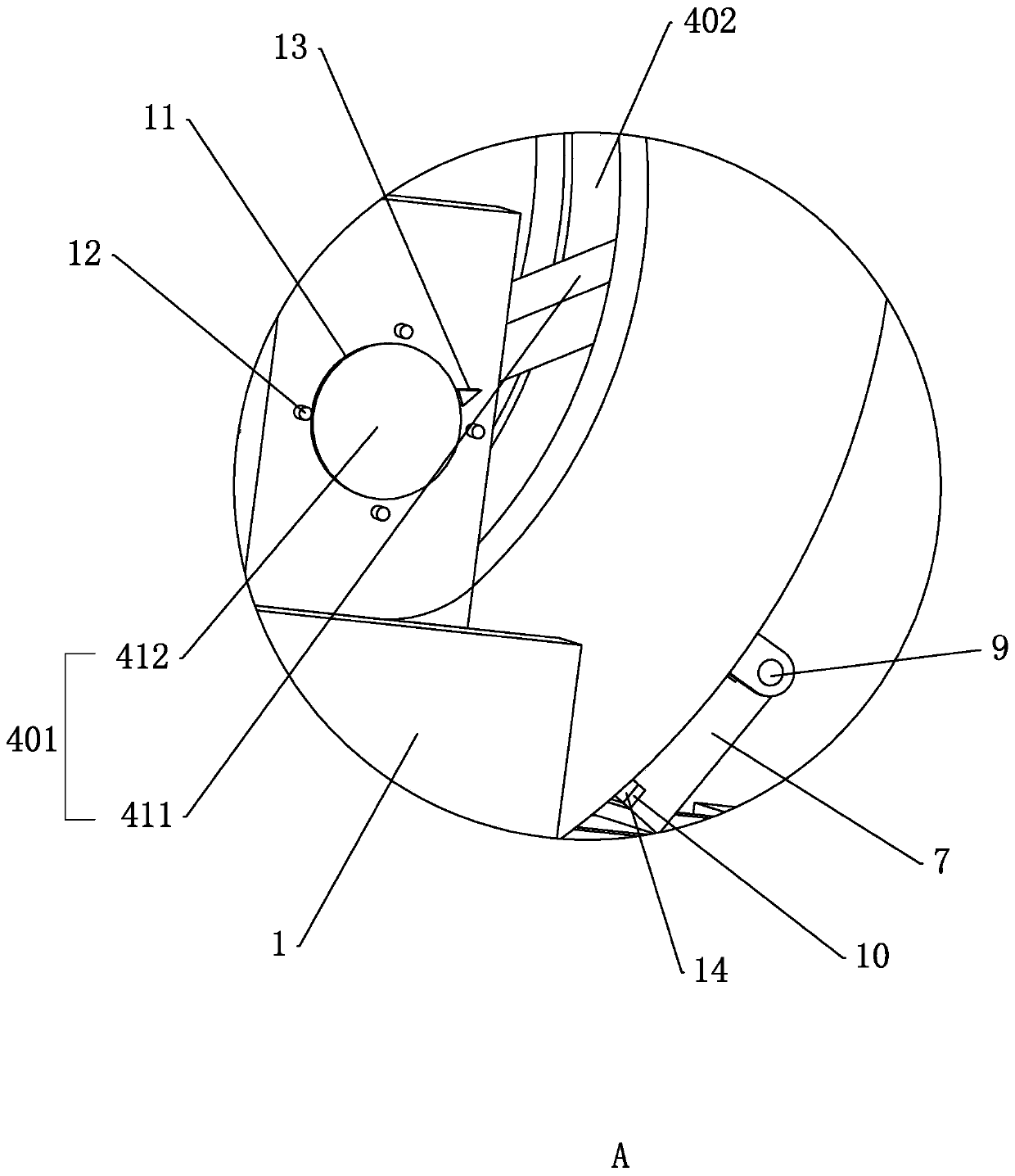

[0036] Embodiment: a kind of logistics sorting device, such as figure 1 Shown, comprise frame 1, be provided with first conveying roller mechanism 2 and be positioned at the second conveying roller mechanism 3 below first conveying roller mechanism 2 on frame 1; The first roller 201 and the first drive motor 202 distributed in the length direction, the first roller 201 is rotatably arranged on the frame 1, the first drive motor 202 is installed on one side of the frame 1, each first roller 201 A first driving motor 202 is connected to the top, and the first driving motor 202 works to drive the first roller 201 to rotate, so as to drive the goods to be conveyed along the length direction of the frame 1 .

[0037] The second conveying roller mechanism 3 includes a roller frame 301 extending along the width direction of the frame 1, a plurality of second rollers 302 and a second drive motor 303, the second rollers 302 are rotatably arranged on the roller frame 301, and along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com