Inner channel cleaning device

A technology for cleaning devices and inner passages, applied to measuring devices, cleaning hollow objects, cleaning methods and appliances, etc., can solve problems such as labor and labor, and achieve the effects of saving equipment and operating costs, simplifying installation requirements, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

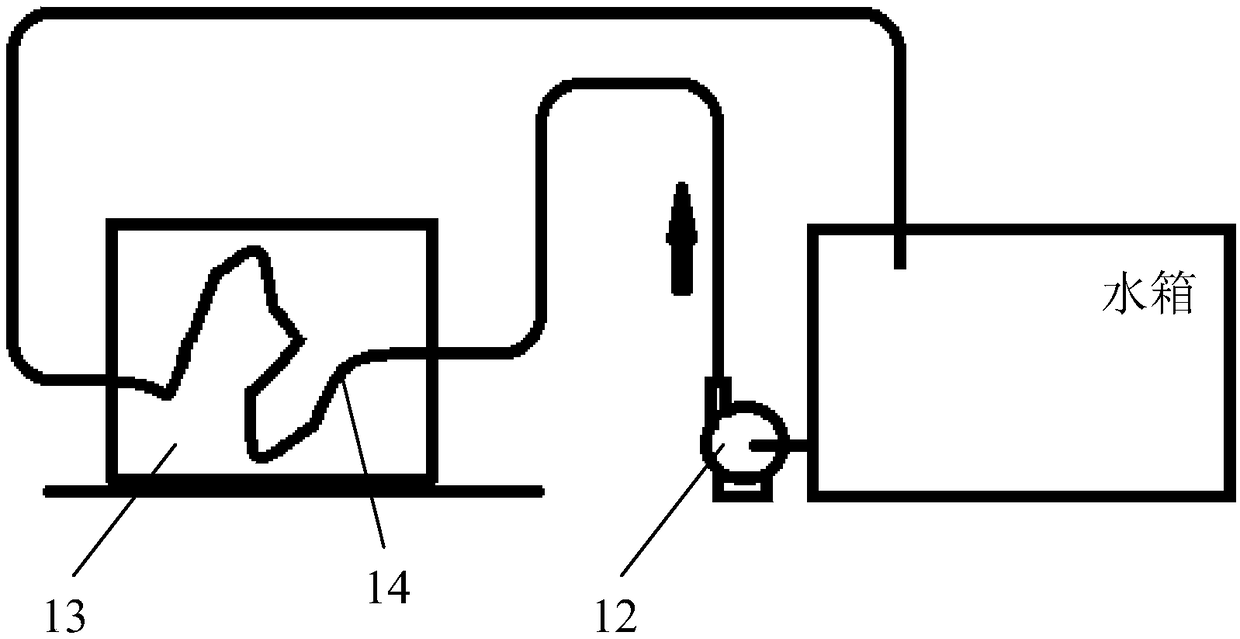

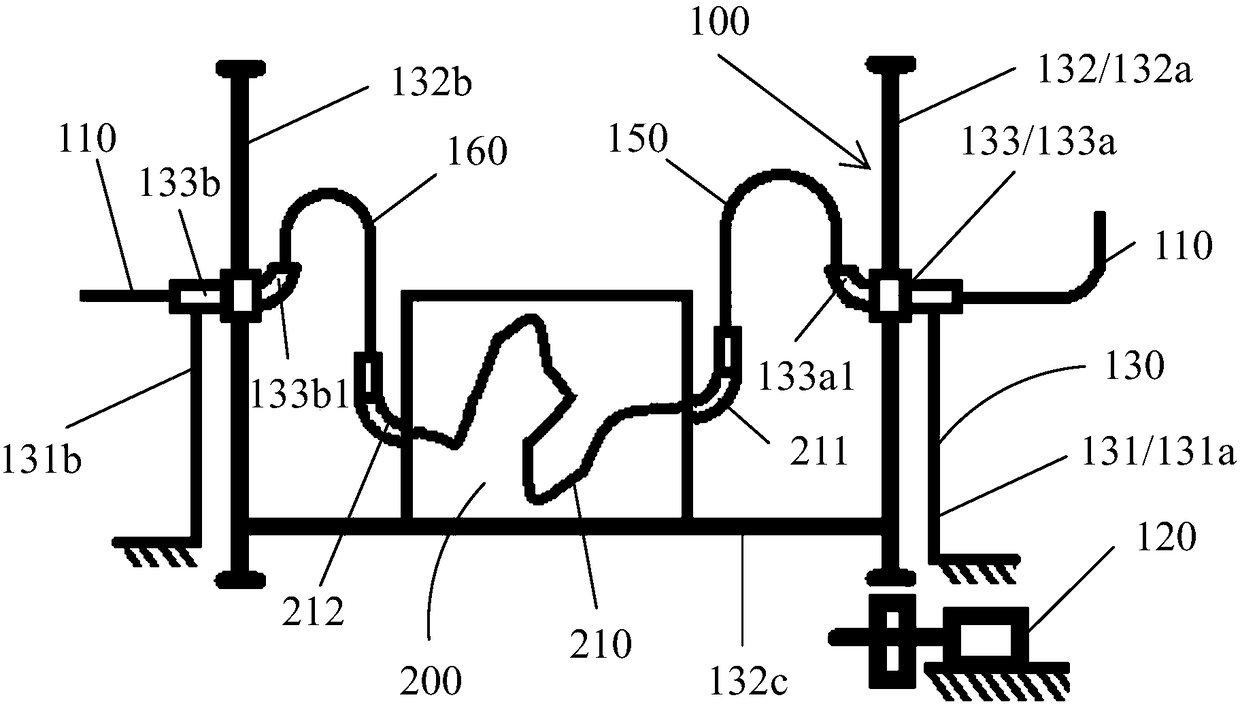

[0061] Such as figure 2 As shown, the inner channel cleaning device 100 of the present invention is connected with a mechanical component 200, and is used for the process steps of cleaning the mechanical component, draining liquid after cleaning, and pressure testing. Through the analysis of the above three processes, the maximum value of the external pressure that the mechanical component that needs to be subjected to the pressure test is the pressure during the pressure test, and under this pressure, the flow rate of the fluid passing through the inner channel is The maximum flow rate that may pass. After the cleaning process, clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com