Shaft radial floating tapping mechanism

A technology of axial radial and fixed mechanism, which is applied in the field of mechanical processing, can solve the problems of tapping taps and low life of taps, and achieve the effects of preventing tapping taps, low manufacturing cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

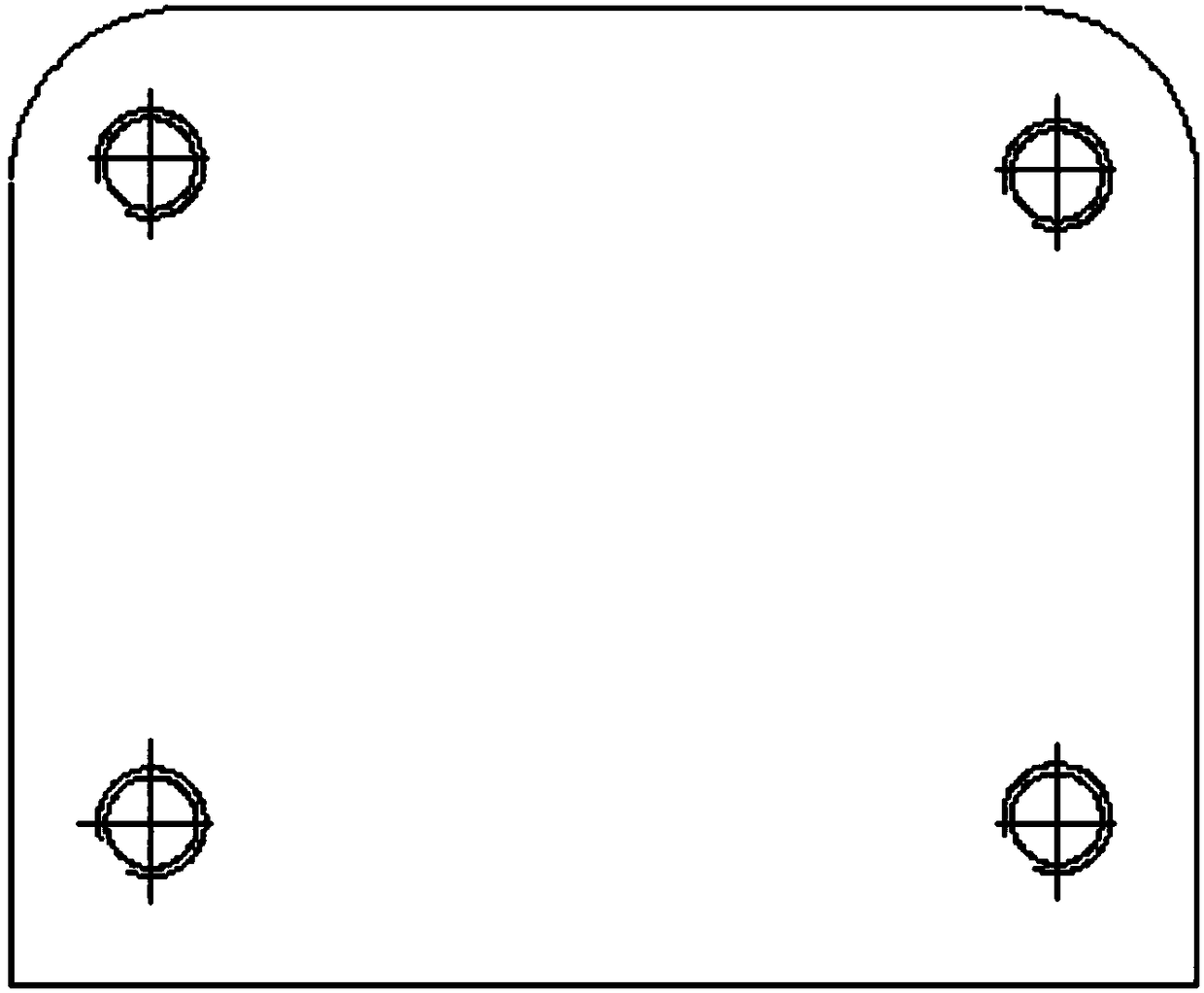

[0042] Such as Figure 2-5 , in this embodiment, the connecting rod kit includes the multi-axis device main shaft 4, the pin hole 13 is opened on the multi-axis device main shaft 4, and the first elastic member and the second elastic member are supported on the multi-axis device main shaft 4, in this embodiment , the floating tapping mechanism is directly connected to the main shaft 4 of the multi-axis device, and only needs to process pin holes on the corresponding positions of the main shaft 4 of the multi-axis device.

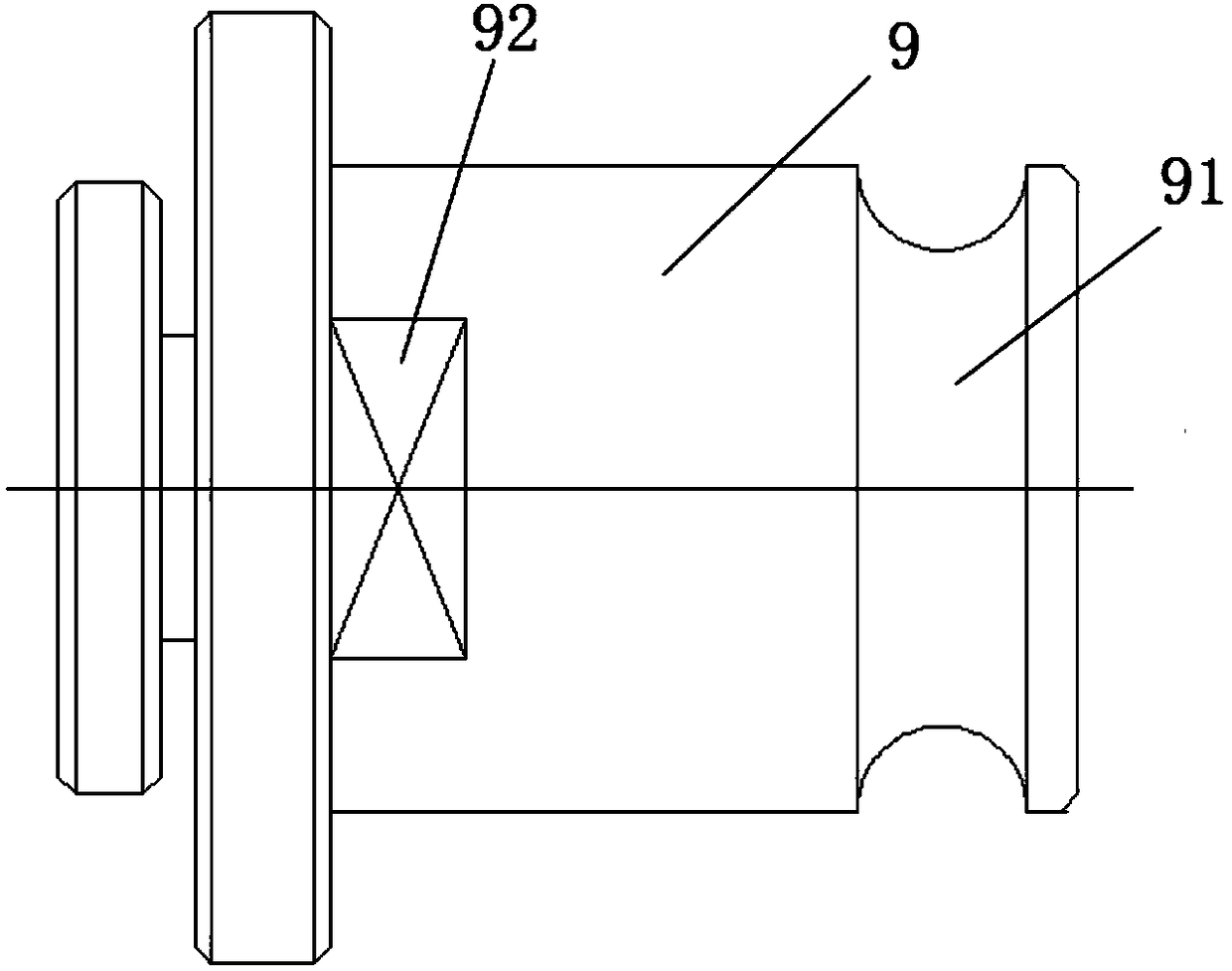

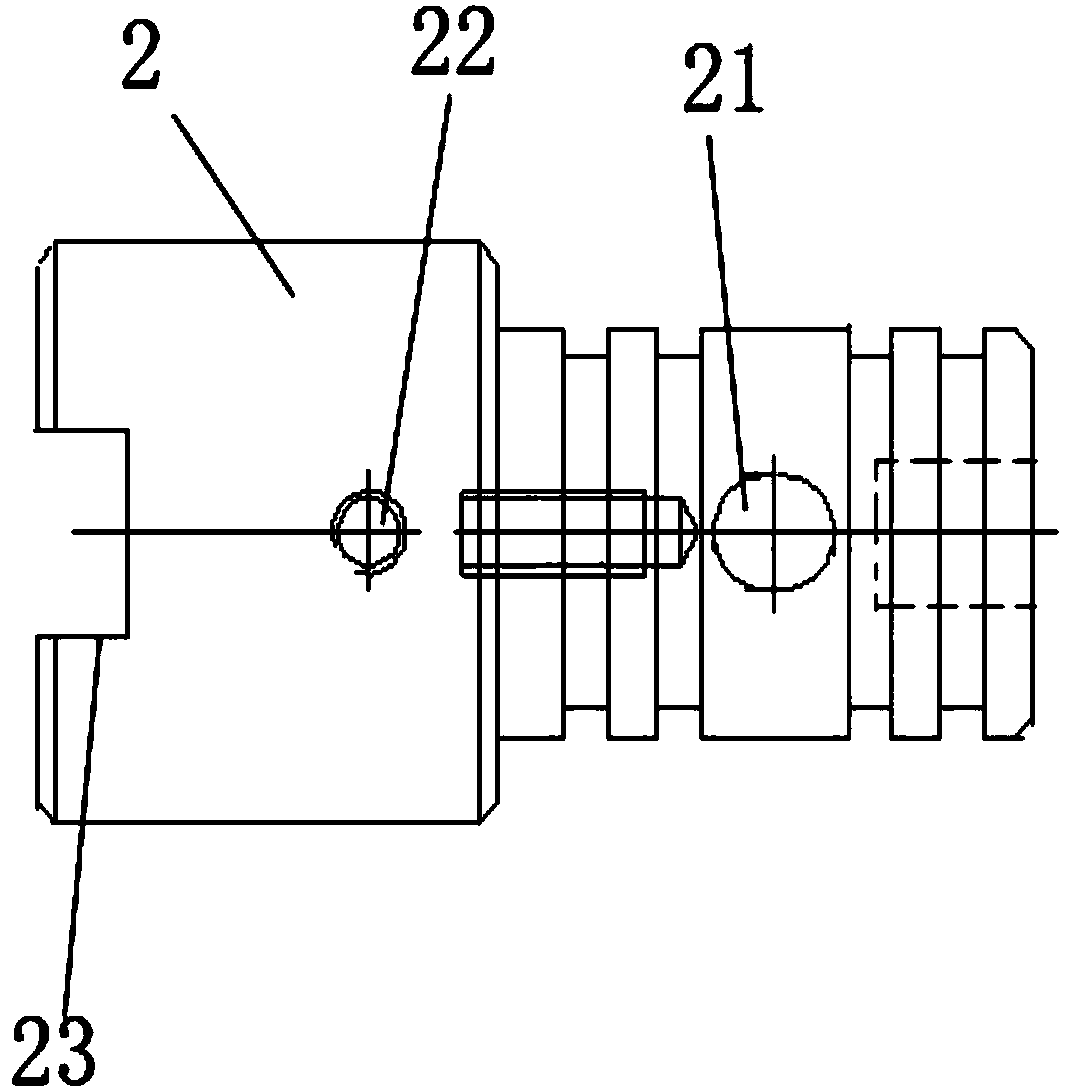

[0043] In this embodiment, the tap fixing mechanism is a quick-insert tap collet 9, an arc-shaped groove 91 is provided on the circumferential surface of the quick-insert tap collet 9, and a screw hole 22 is provided in the radial direction of the floating post 2, and the screw hole 22 The middle thread is fitted with a tap set screw 12, the tap set screw 12 is placed on the arc groove 91, the quick-insert tap collet 9 is provided with a stopper 92, and one ...

Embodiment 2

[0045] Such as Figure 6-10, the post kit includes a floating tapping sleeve 5 and a multi-axis device main shaft 4, the pin hole 13 is opened on the floating tapping sleeve 5, the first elastic member and the second elastic member are supported on the floating tapping sleeve 5, and the multi-axis device The main shaft 4 and the floating tapping sleeve 5 are fixedly connected. In this embodiment, there is no need to process the main shaft 4 of the multi-axis device, and the floating tapping sleeve 5 is used to make an integral floating mechanism, and then fixedly installed with the main shaft 4 of the multi-axis device.

[0046] In this embodiment, the tap fixing mechanism includes an ER collet 10 for installing the tap 1 and a nut 11 for locking the ER collet 10, and the floating post 2 is provided with a slot matching the shape of the ER collet 10 , the nut 11 is sleeved on the floating connecting rod 2 and is threadedly connected with the floating connecting rod 2 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com