Bicycle parking garage mechanical gripper

A technology of mechanical grippers and bicycles, applied to manipulators, buildings where cars are parked, buildings, etc., can solve problems such as many fault points, inability to miniaturize, and high noise, and achieve a reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

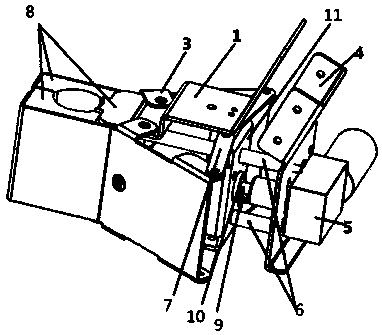

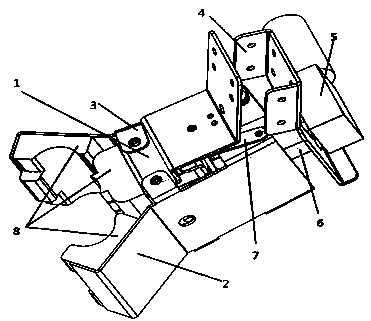

[0012] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] like Figure 1-2 As shown, a mechanical gripper for a bicycle parking garage includes a pair of gripper plates 2 for grabbing the front wheels of bicycles, one side of the gripper plate 2 is extended with a front end shaft 3, and one side of the front end shaft 3 is connected with A fixed plate 1, one end of the fixed plate 1 is connected with a connecting plate 4, a guide rod 6 and a T-shaped screw rod 9 run through the connecting plate 4, and a movable plate 11 is overcoated at one end of the guide rod 6, and the movable plate 11 The slidable direction is the front-to-back direction, the movable plate 11 is provided with a nut 10, and the T-shaped screw 9 runs through the nut 10, and the movable plate 11 is driven to move forward and backward through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com