EVOH-based (ethylene vinyl alcohol copolymer-based) thermoplastic vulcanized rubber with high air barrier properties and preparation method thereof

A thermoplastic vulcanizate and gas barrier technology, applied in the field of polymer materials, can solve the problems of poor fatigue durability and non-recyclable products, and achieve the effect of excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

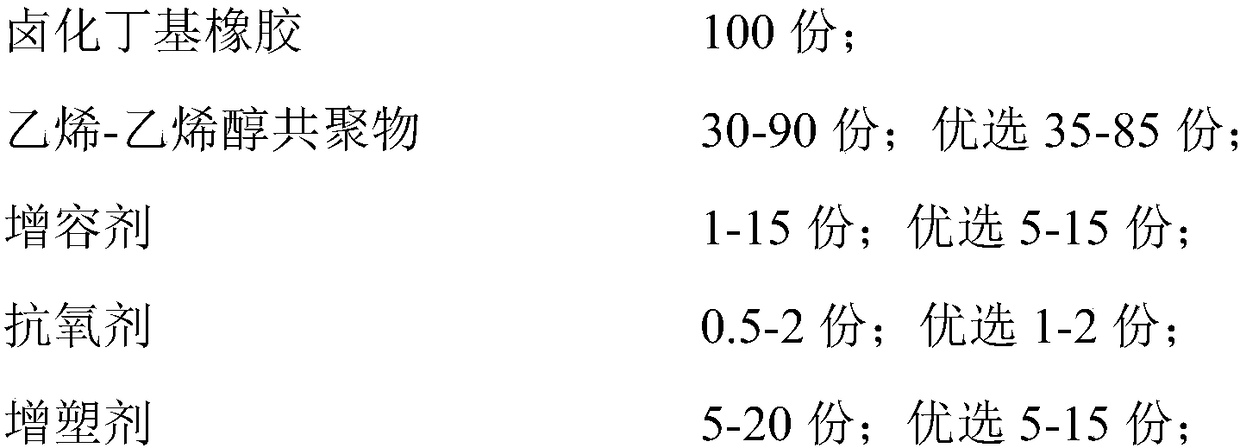

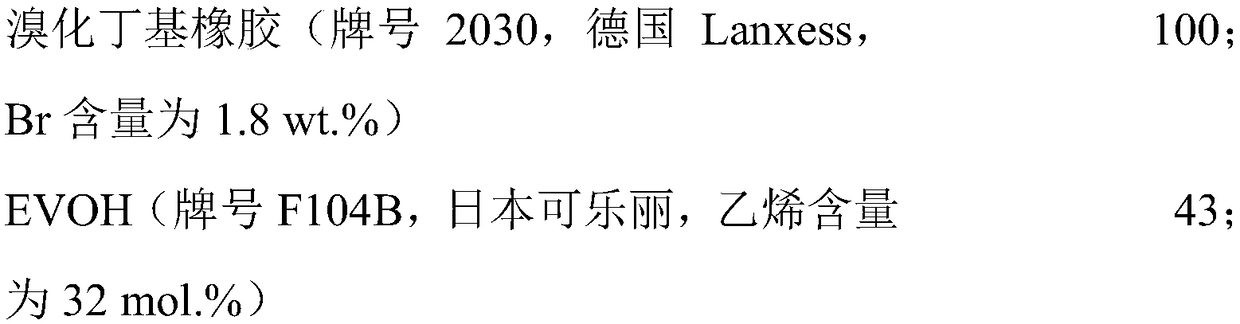

[0025] The basic composition and mass parts of the selected raw materials are as follows:

[0026]

[0027]

[0028] According to the above formula, mix the dried EVOH and bromobutyl rubber at 200°C, add glycidyl methacrylate grafted ethylene-vinyl acetate copolymer (EVA-g-GMA) and antioxidant in proportion, After mixing evenly, discharge the material and cool to room temperature; then mix it with plasticizer and vulcanizing agent at room temperature to obtain a rubber-plastic premix; first, put 1 / 2 of the rubber-plastic premix in a twin-screw extruder, set The screw temperature was 160°C, the rotation speed was 300rpm, dynamic vulcanization was performed for 8 minutes, and then the remaining rubber and plastic premix was added and dynamic vulcanization was performed for 5 minutes to obtain a halogenated butyl rubber / ethylene-vinyl alcohol copolymer thermoplastic vulcanizate. The TPV was pressed into a 2mm thick sheet according to the standard and the performance was tes...

Embodiment 2

[0032] The basic composition and mass parts of the selected raw materials are as follows:

[0033]

[0034]

[0035] According to the above formula, mix the dried EVOH with brominated polyisobutylene-p-methylstyrene rubber at 180°C, and add maleic anhydride grafted ethylene-octene copolymer (POE-g-MAH) and Antioxidant, after being mixed evenly, the material is cooled to room temperature; then mixed with plasticizer and vulcanizing agent at room temperature to obtain a rubber-plastic premix; first, 1 / 3 of the rubber-plastic premix is placed in twin-screw extrusion In the machine, set the screw temperature at 180°C, the rotation speed at 400rpm, dynamic vulcanization for 8 minutes, and then add the remaining rubber-plastic premix and dynamic vulcanization for 7 minutes. The TPV was pressed into a 2mm thick sheet according to the standard and the performance was tested. The performance is shown in Table 1.

Embodiment 3

[0039] The basic composition and mass parts of the selected raw materials are as follows:

[0040]

[0041]

[0042] According to the above formula, mix the dried EVOH and chlorobutyl rubber at 210°C, add glycidyl methacrylate grafted ethylene-vinyl acetate copolymer (EVA-g-GMA) and antioxidant in proportion, After mixing evenly, discharge the material and cool to room temperature; then mix it with plasticizer and vulcanizing agent at room temperature to obtain a rubber-plastic premix; first, put 1 / 4 of the rubber-plastic premix in a twin-screw extruder, set The screw temperature was 190°C, the rotation speed was 500rpm, dynamic vulcanization was performed for 4 minutes, and then the remaining rubber-plastic premix was added and dynamic vulcanization was performed for 8 minutes. The TPV was pressed into a 2mm thick sheet according to the standard and tested for performance. The performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com