Light-emitting casing

A technology of housing and light-emitting unit, which is applied to semiconductor devices, light sources, plane light sources, etc. of light-emitting elements, can solve the problems of increasing the number and thickness of components in the housing and increasing the number of LED light bars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

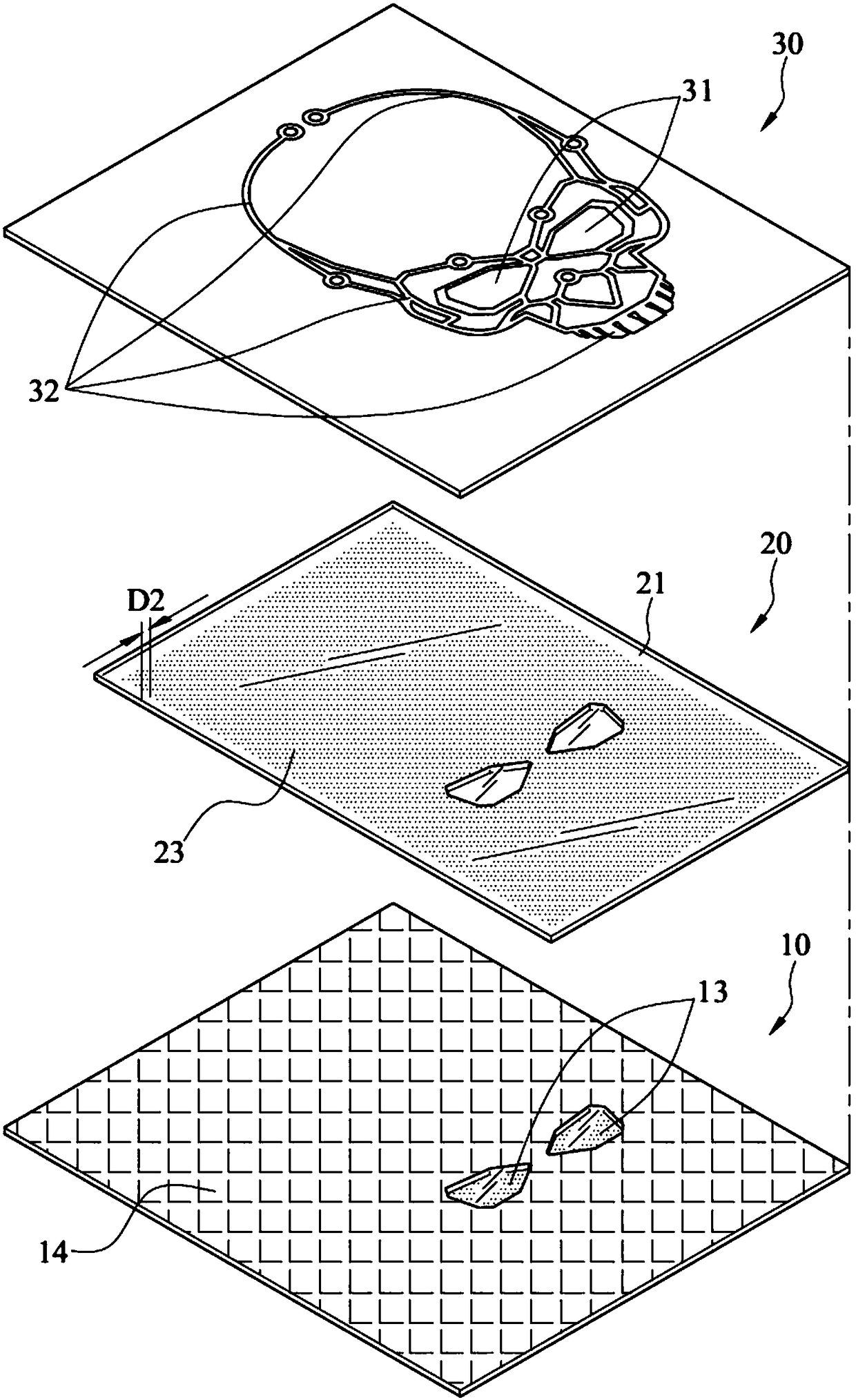

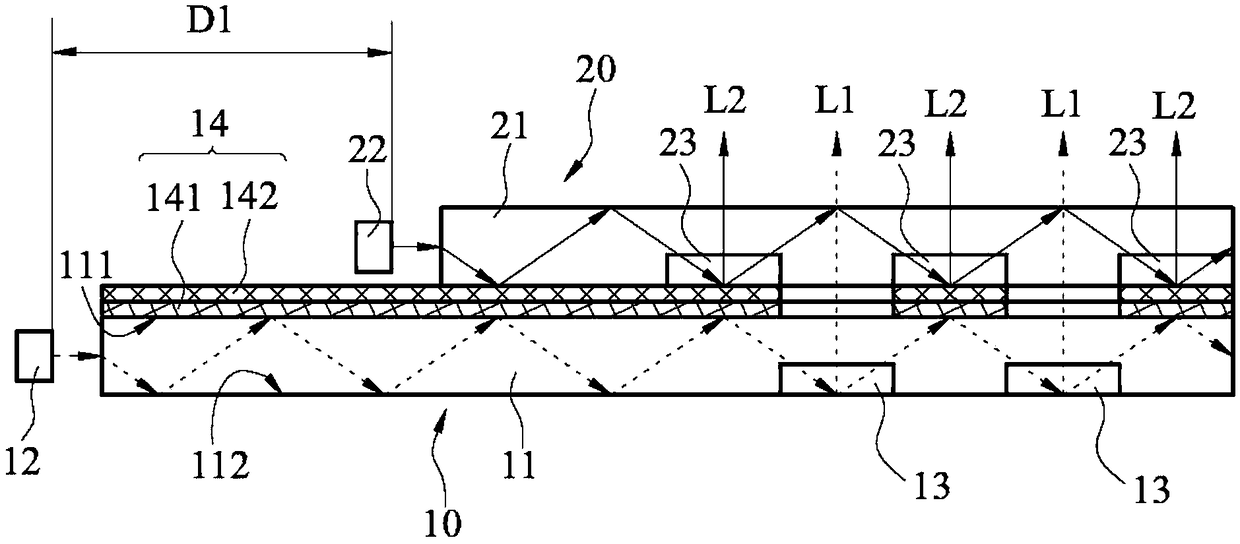

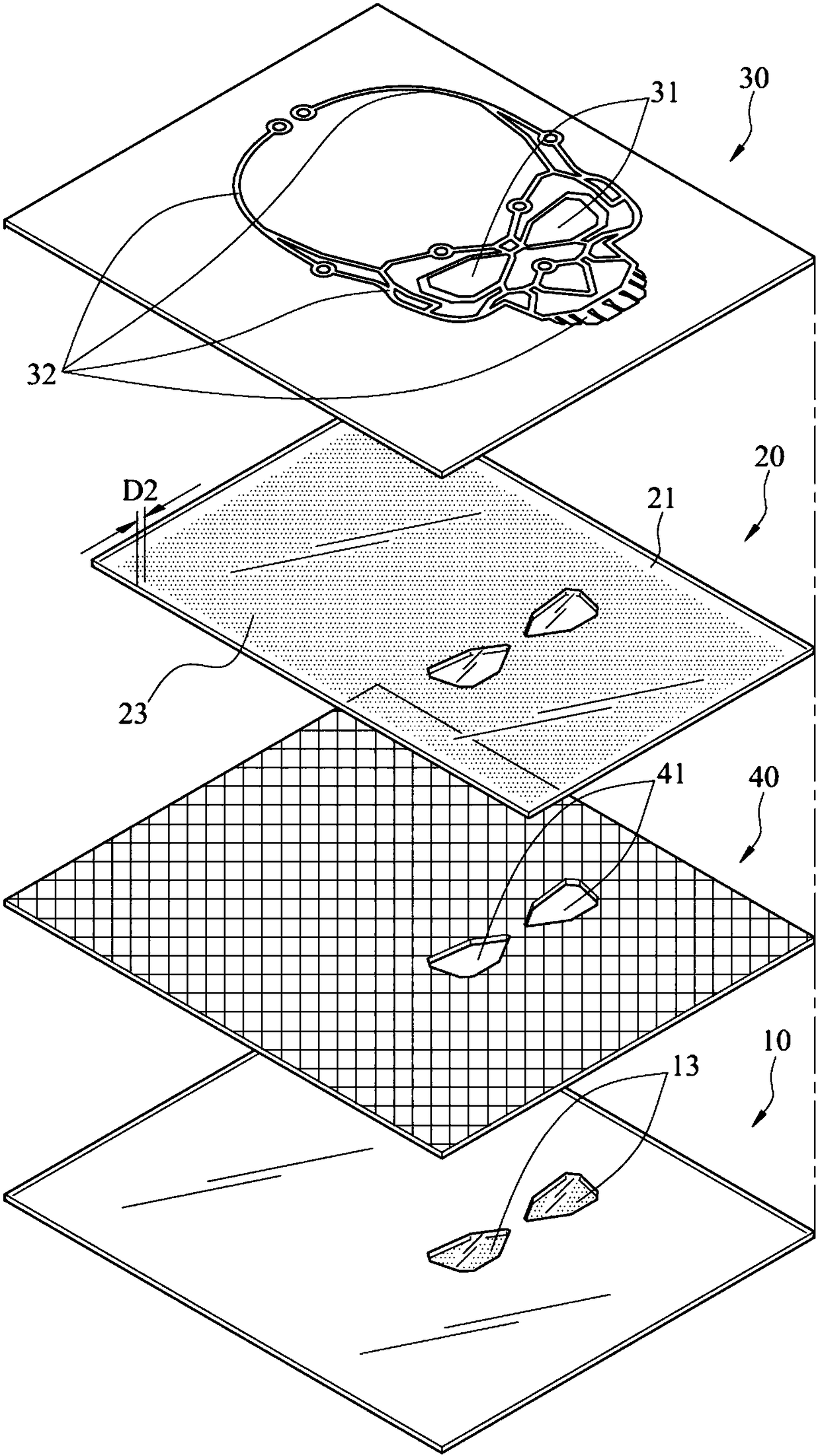

[0025] Please also see figure 1 and figure 2 , figure 1 It is an exploded view of the first embodiment of the light-emitting housing of the present invention, figure 2 It is a partial sectional view of this embodiment. Such as figure 1 As shown, the light-emitting housing of this embodiment includes a first light-emitting module 10 , a second light-emitting module 20 , a shield and a housing 30 . The second light emitting module 20 is disposed above the first light emitting module 10 , the shielding member is disposed between the first light emitting module 10 and the second light emitting module 20 , and the housing 30 is further disposed above the second light emitting module 20 . exist figure 2 The uppermost housing 30 is omitted. The casing 30 can be a casing of any electronic component, such as a display screen, a laptop, or a tablet, and its size and shape are not limited. The casing shown in this embodiment is only an example.

[0026] Such as figure 1 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com