Heliostat bracket

The technology of heliostat and mirror frame is applied in the field of small solar thermal power generation, which can solve the problems of low stability of mirror frame structure, low reflection accuracy of heliostat, easy deformation, etc., so as to reduce the risk of deformation and improve the supporting capacity. , the effect of increasing the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

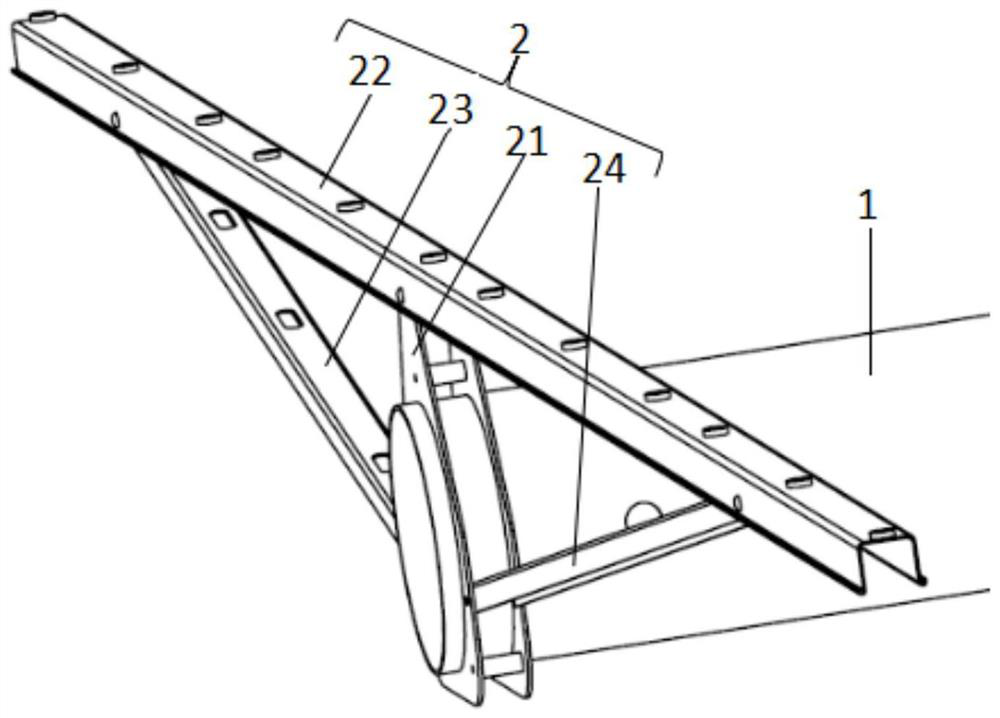

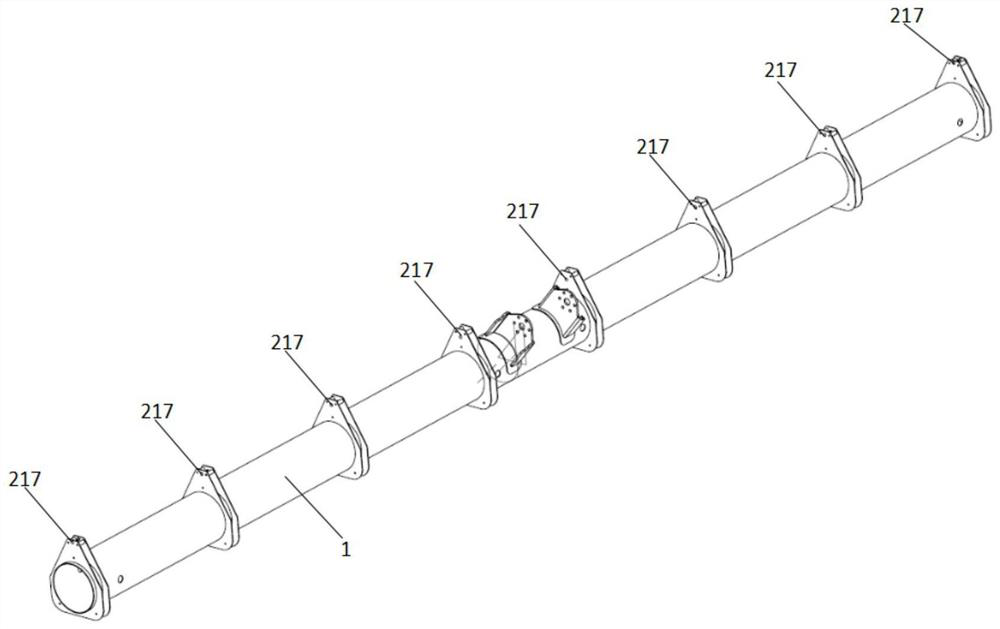

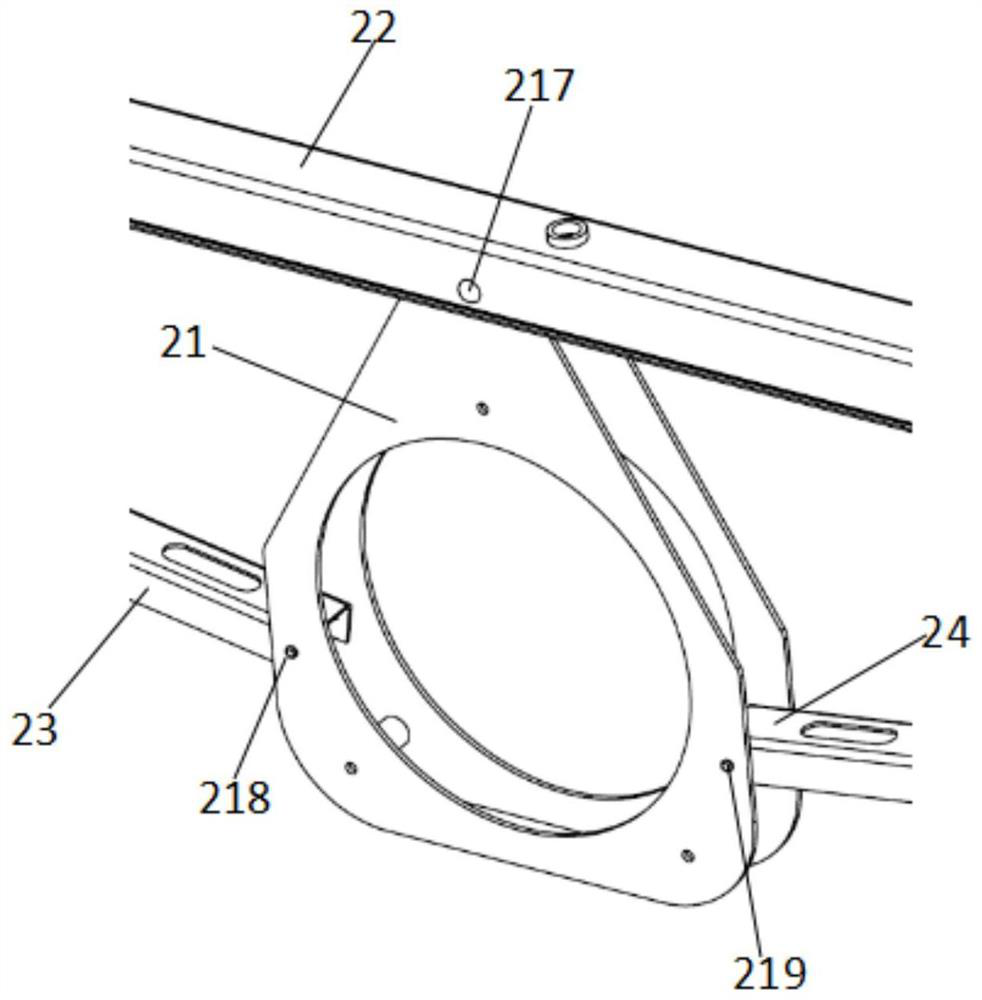

[0045] A heliostat frame, see figure 1 , figure 2 , comprising a main beam 1 and several support units 2 arranged at intervals on the main beam 1, the support units 2 are fixed on the main beam 1 along the extension direction of the central axis of the main beam, wherein each support unit 2 includes a fixed A central support 21 sleeved on the main beam 1, a secondary beam 22 connected to the main beam 1 through the central support 21,

[0046] The central bracket 21 includes a first support piece 211 and a second support piece 212 arranged in parallel and spaced apart from each other, and the first support piece 211 and the second support piece 212 are fixedly connected by at least one support member between them. ; Wherein, the first support piece 211 is provided with a first through hole, and the second support piece is provided with a second through hole, and the first through hole and the second through hole form a central bracket through hole 214;

[0047] The central ...

Embodiment 2

[0067] A heliostat, comprising: a reflective surface of the heliostat, a heliostat frame connected to the reflective surface, the heliostat frame is the heliostat mirror described in any one of embodiment 1 shelf.

[0068] A field of heliostats, including the above-mentioned heliostats.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com