Solar cell and preparation method thereof

A technology of solar cells and solar cells, applied in the field of solar cells, can solve the problems of carrier generation, recombination centers, and limited effects, and achieve the effects of low cost, simple manufacturing process, and increased thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

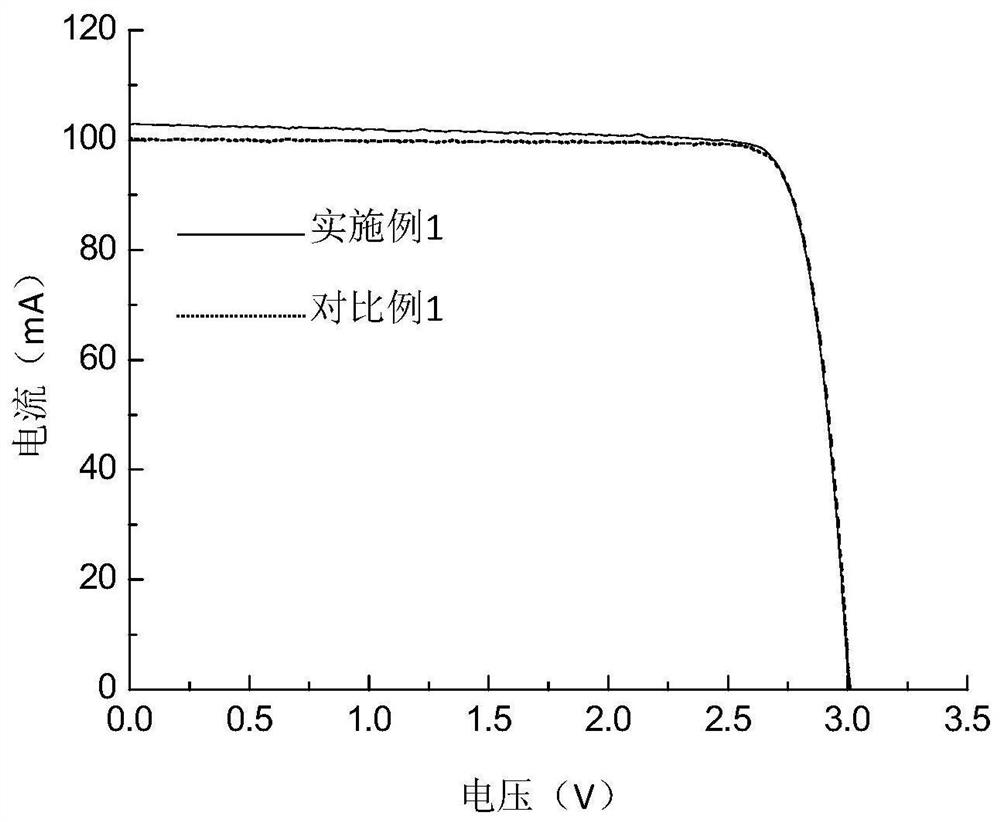

Embodiment 1

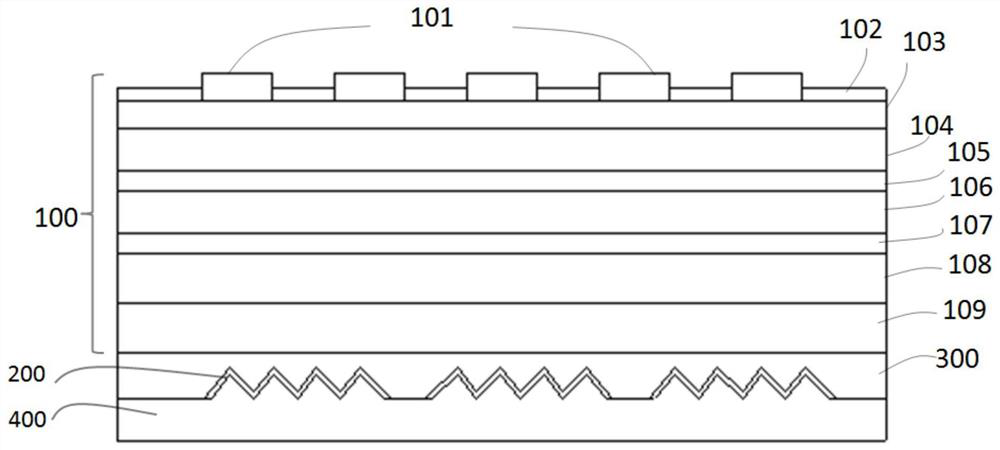

[0084] In this embodiment, a solar cell is prepared, and the specific process is as follows:

[0085] S1. Epitaxially grow AlAs sacrificial layer, N-type GaAs contact layer, GaInP battery, first tunnel junction, GaAs battery layer, second tunnel junction, lattice buffer layer, GaInAs battery and P-type GaInAs contact layer on GaAs substrate in sequence ;

[0086] S2. On the surface of the P-type GaInAs contact layer, use photolithography to make a trench pattern in the shape of an isosceles triangle with a base angle of 15°, and protect the area outside the trench pattern; then dry-etch the P-type GaInAs Contact layer, get groove, clean and remove photoresist;

[0087] S3. Photolithographic protection of the surface of the component obtained in step S2, the area outside the groove, the material in the area where the groove is located is silicon dioxide, the thickness is 150nm back insulating layer, the setting method is evaporation, and then the photoresist is removed by clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com