Prefabricated Greenhouse Structures

A structure and assembly technology, applied in greenhouse cultivation, botany equipment and methods, horticulture, etc., can solve problems such as rupture of interconnected parts, airtightness damage of greenhouse structures, etc., and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

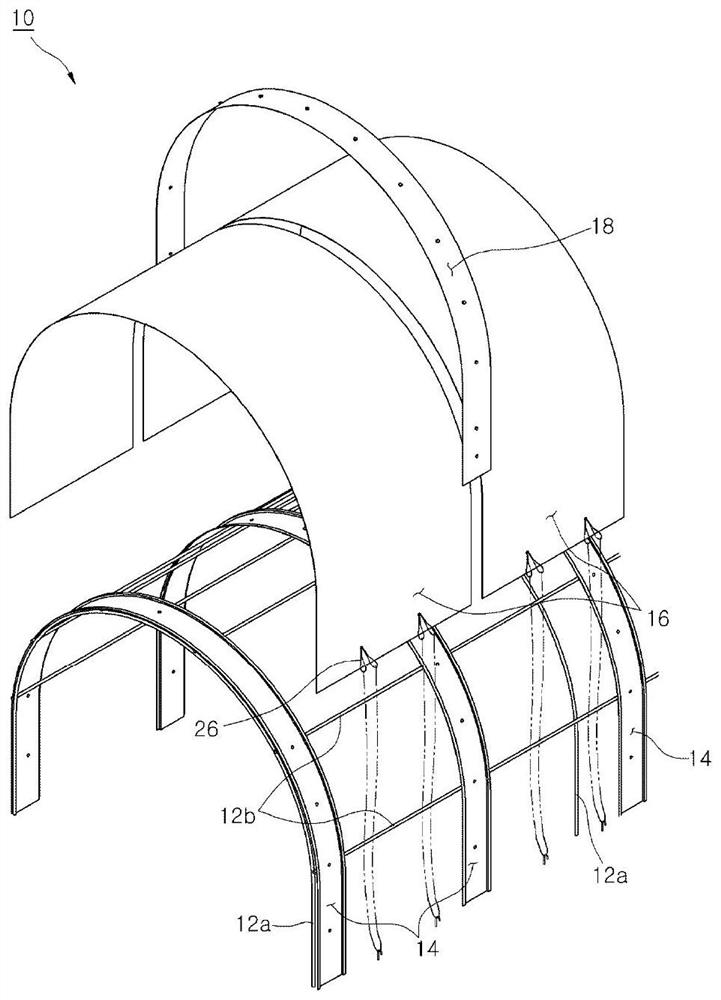

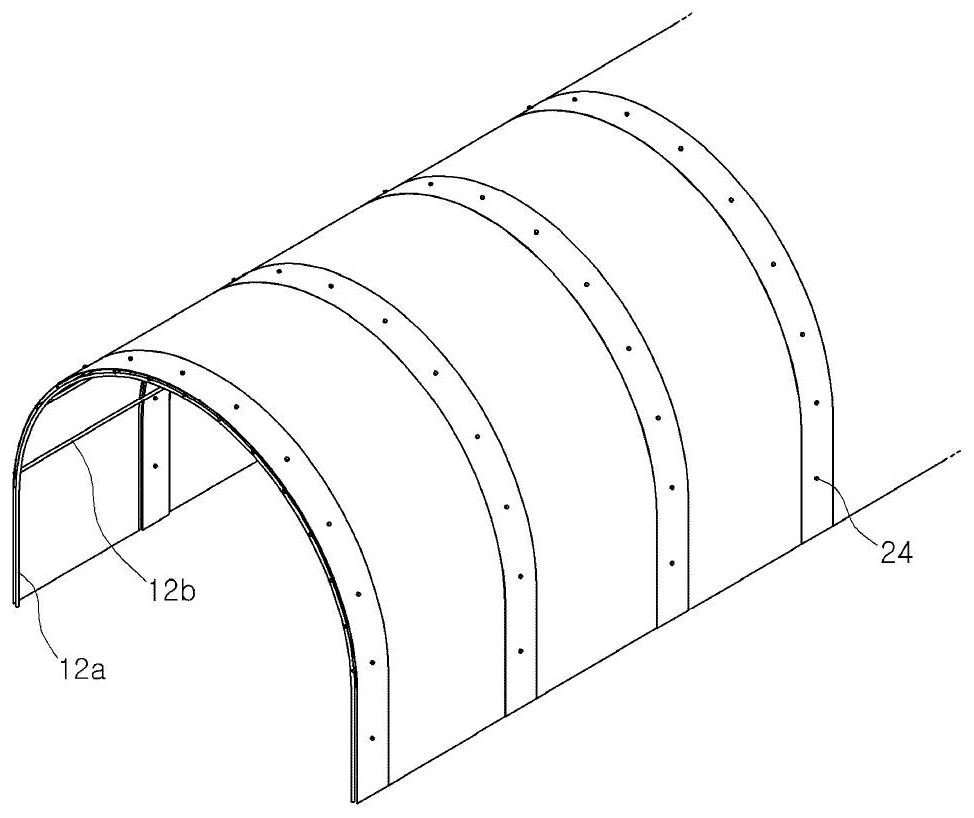

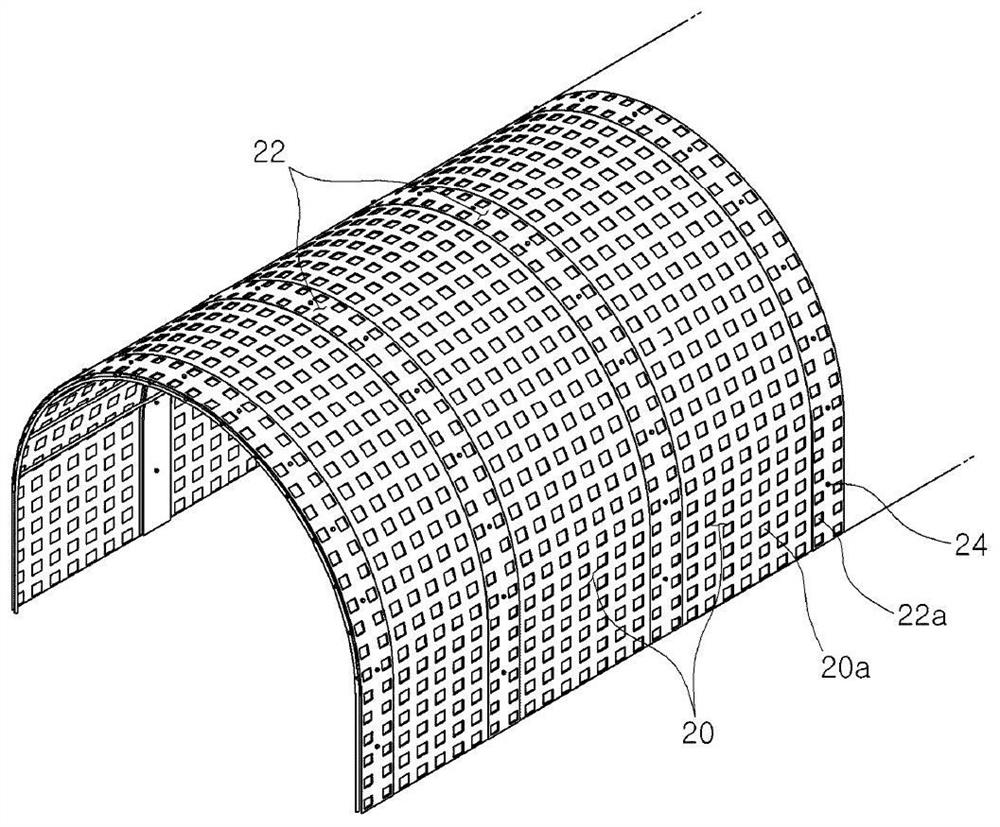

[0056] The best embodiment of the present invention is to provide the following prefabricated greenhouse structure, that is, the prefabricated greenhouse structure of the present invention includes: a supporting structure, which passes through the cultivated field in a manner corresponding to the set width and length; Formed by connecting a plurality of formworks and brackets; and a covering material, used to cover the periphery of the supporting structure, the above-mentioned assembled greenhouse structure is characterized in that the above-mentioned covering material includes: a base plate, as having a set width and length The strip-shaped plate is set by being supported by the above-mentioned formwork and / or bracket; the cover plate, as a plate with different widths and different lengths that have been set, is placed on the backing plate with a part of the edge of the bottom surface overlapping. The edge parts in the width direction are arranged; the cover plate, as a strip-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com