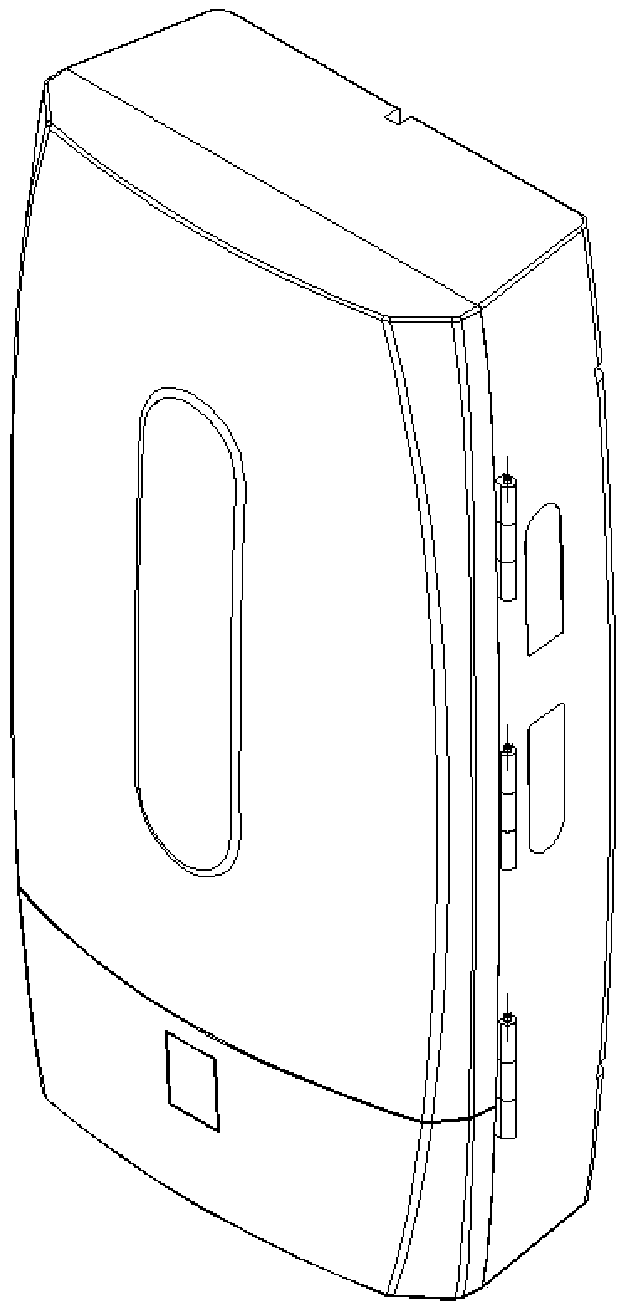

Paper drawing machine with rebound type cutter structure

A technology of paper pumping machine and cutting knife, which can be applied to home appliances, etc. It can solve the problems of difficulty in changing paper rolls and inconvenient paper towels, and achieve the effects of convenient and quick replacement, reduced labor costs, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

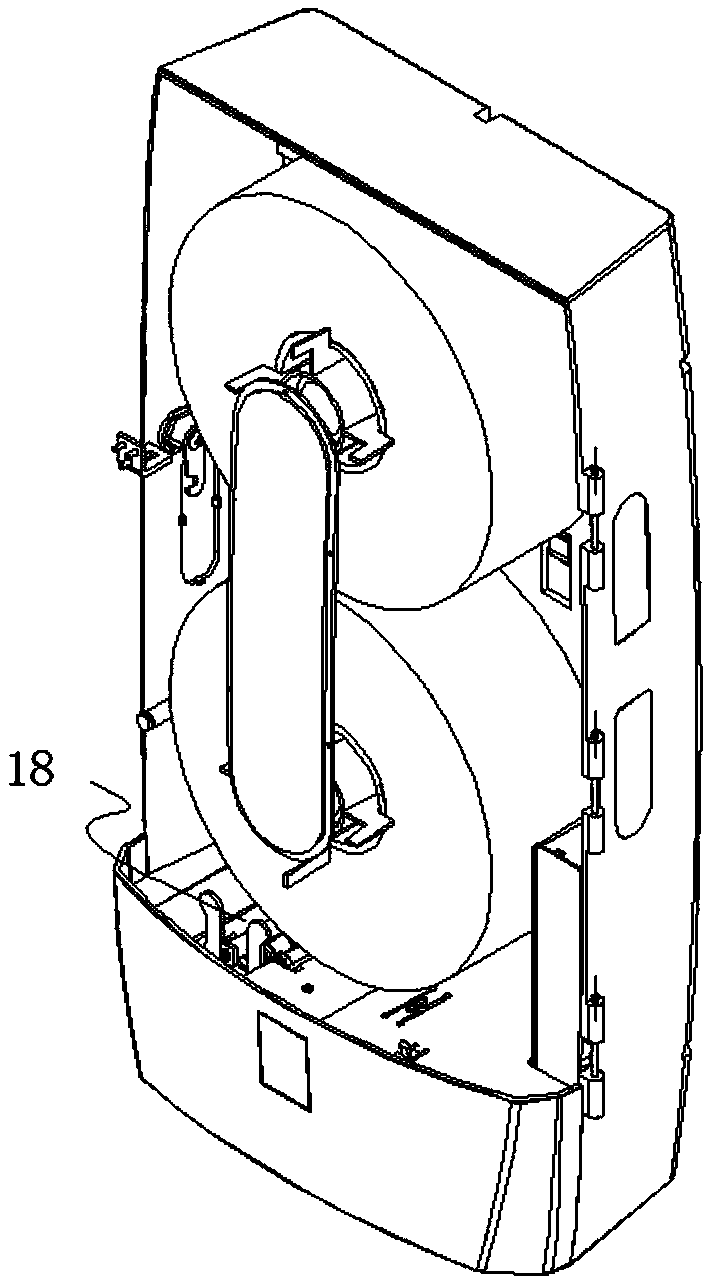

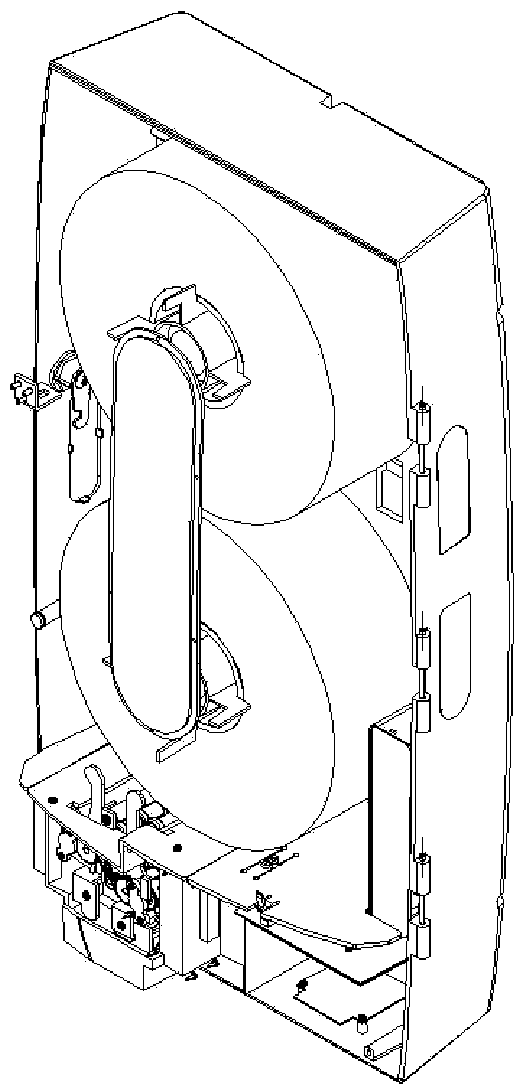

Embodiment 1

[0045] A paper pumping machine with a rebound cutter structure, comprising a body 10, a paper towel chamber is arranged on the upper part of the body 10, a movement is arranged on the lower part of the body, and the movement includes a placing frame 1 fixed on the body 10, placed Both sides of the upper end of the frame 1 are provided with support plates 2, and between the two support plates 2 are provided with a first roller shaft 310 and a third roller shaft 320 below the first roller shaft 310, and the left and right sides of the support plate 2 The two sides are respectively provided with a first rotating plate 410 and a second rotating plate 420, both ends of the first rotating plate 410 and the second rotating plate 420 are bent downward to form a bending part 5, and the bending part 5 is connected with the placing frame. The outer wall of 1 is rotationally connected, and the upper ends of the first rotating plate 410 and the second rotating plate 420 are respectively pro...

Embodiment 2

[0048] On the basis of Embodiment 1, one end of the first roller shaft 310 and the third roller shaft 320 are respectively sleeved with the first gear 311 and the third gear 321 after passing through the support plate 2, and one end of the second roller shaft 330 After passing through the left support plate 210, a second gear 331 engaged with the first gear 311 is sleeved, and one end of the fourth roller shaft 340 passes through the right support plate 220, and a fourth gear 331 engaged with the third gear 321 is sleeved. gear341.

[0049] In this embodiment, through gear meshing transmission, the first gear 311 meshes with the second gear 321, and the third gear 331 meshes with the fourth gear 341. When the driving device drives one gear to rotate, the two meshed gears rotate in opposite directions, driving The paper moves downward, and the paper is conveyed by a paper output unit through a driving mechanism, and the structure is simple and reasonable.

Embodiment 3

[0051] On the basis of Embodiment 1, the other ends of the first roller shaft 310 and the third roller shaft 320 respectively pass through the support plate 2 and the left support plate 210 and are connected with the first spring 710, the second roller shaft 320 and the fourth The other end of the roller shaft 340 respectively passes through the support plate 2 and is connected with the second spring 720 after the support plate 2 .

[0052] In this embodiment, through the first spring 710 and the second spring 720, the tight connection between the first roller shaft 310 and the second roller shaft 320, between the third roller shaft 330 and the fourth roller shaft 340 is ensured respectively, so that through After manually rotating the first rotating plate 410 and the second rotating plate 420, when restoring the first rotating plate 410 and the second rotating plate 420, ensure that the first roller shaft 310 and the second roller shaft 320, the third roller shaft 330 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com