Weight reducing device

A technology of decelerating stepper motor and spring box, applied in the field of medical rehabilitation, can solve the problems of lack of a larger adjustable range, difficult to adjust the demand for more variable, motor noise response speed, etc., so as to increase the use continuity, Low cost, lightweight and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

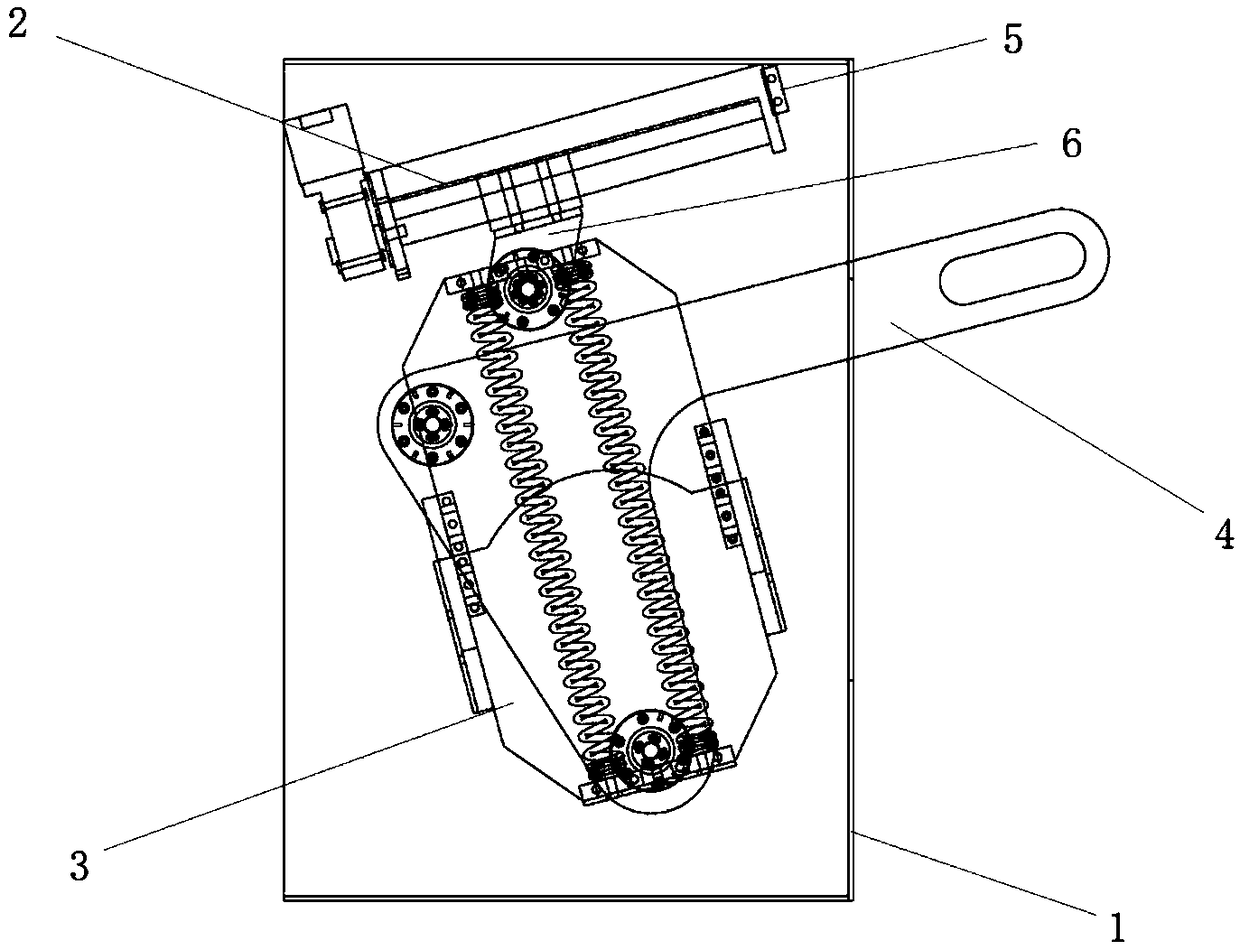

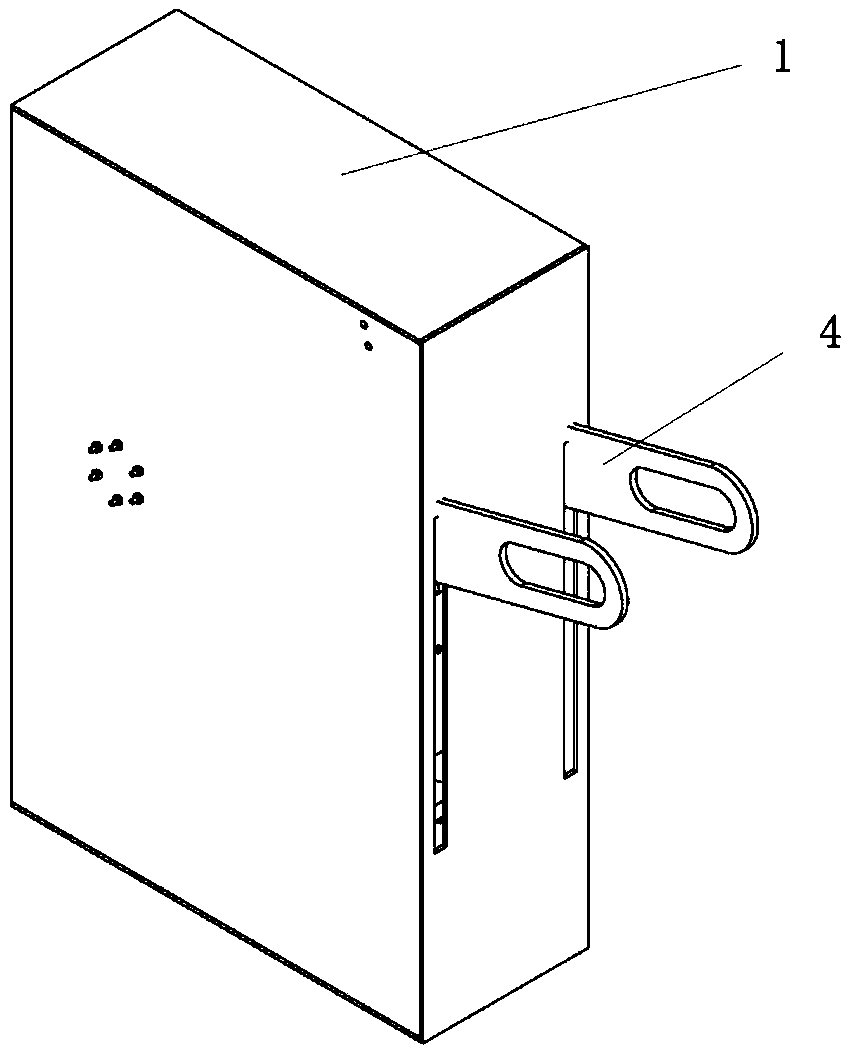

[0028] A weight reduction device design, as shown in 1 and 2, consists of a housing 1, a linear guide 2, a spring box 3, and a force arm 4.

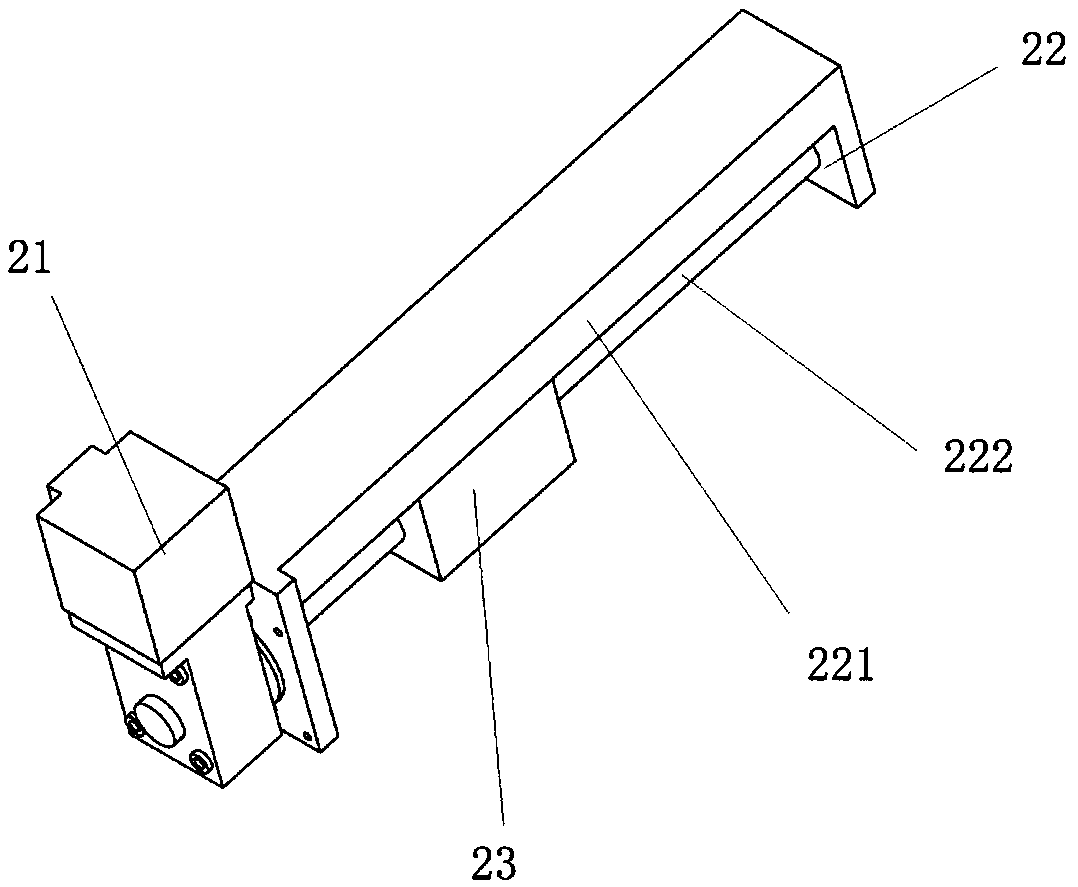

[0029] Such as image 3 As shown, the linear guide rail 2 is composed of a deceleration stepping motor 21, a screw slide 22, and a slider 23. The screw slide 22 is composed of a screw slide 221 and a screw 222. The slider 23 is mounted on the screw 222 and can move along the screw rod 222. The deceleration stepper motor 21 is installed on a side wall of the screw slide rail 221 by screws. The screw rod 222 passes through the side wall and is connected to the deceleration stepper motor 21. The deceleration stepper motor 21 Drive the screw 222 to rotate, and the screw 222 drives the slider 23 to move, combining figure 1 As shown, the other side wall of the screw slide rail 221 is connected to the housing 1 through the connecting plate 5. Specifically, the side wall is connected to the connecting plate 5 through screws, and the connecting plate...

Embodiment 2

[0033] The general structure is consistent with the embodiment, the difference is that the housing is made into a hollow design except where the force is concentrated.

[0034] The working principle of the weight reduction device design described in the above embodiment is: Image 6 Shown, F 1 For weight reduction, L 1 Is the length of the arm, F 2 Is the spring preload, L 2 Is the length of arm two, L 3 Is the spring arm, x is the adjustment stroke, L is the initial length of the spring, L′ is the total length of the spring after stretching, ΔL is the spring extension, and K is the spring stiffness coefficient. When designing the weight reduction device, specify the screw and vertical The straight direction is at an angle α, and the angle formed by the force arm one and the force arm two is also α, the angle between the spring and the force arm two is β, and the offset between the force arm fulcrum and the screw rod is a. It can be seen from the figure that the sliding block is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com