Pneumatic fire extinguishing gun system

A fire extinguishing cannon, pneumatic technology, applied in the field of fire extinguishing cannon system, can solve the problems of potential safety hazards of pyrotechnic products, large size, short range, etc., and achieve the effects of avoiding potential safety hazards, high aiming accuracy, and controllable costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

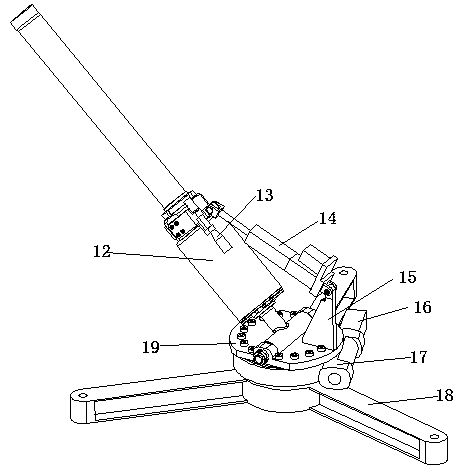

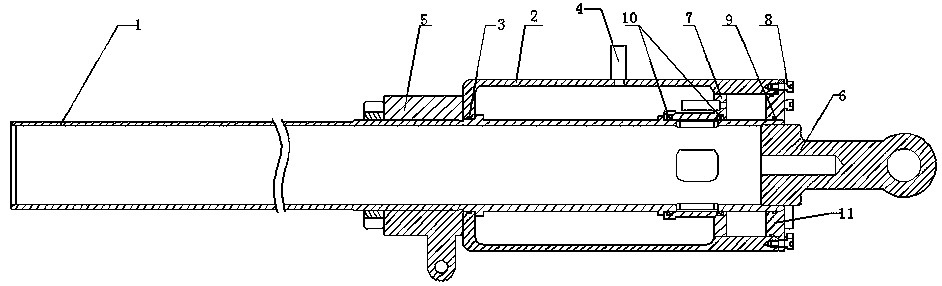

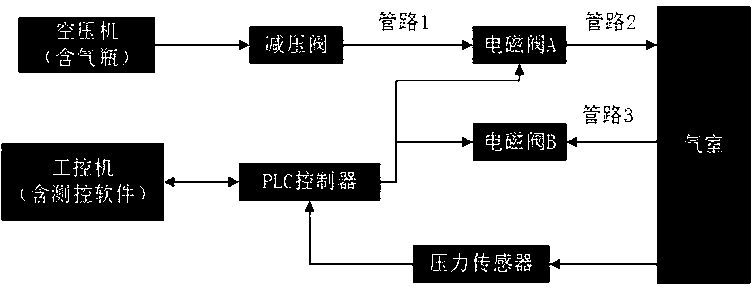

[0014] Such as Figure 1-3 As shown, a pneumatic fire extinguishing cannon system includes an air cannon 12, an electric cylinder 14, a support plate 15, a recoil device 18, a base 19, and an electrical control circuit. The base 19 is fixed on the recoil device 18 through a rotary support 17. The base 19 is provided with a motor 16, and the base 19 is fixed with an air cannon 12 through a support plate 15 and an electric cylinder 14. The air cannon 12 is provided with a sight 13, and the air cannon 12 includes a gun barrel 1, an air chamber 2, and a front trunnion 5 , the rear trunnion 6, the rear end of the gun barrel 1 runs through the air chamber 2 and is fixed with the air chamber, and the end is provided with a rear trunnion 6, the rear end of the air chamber 2 is fixed with an end cover 11, and the front end and the gun barrel 1 are connected. The sealing ring I3, the barrel 1 at the front end of the air chamber 2 is provided with a front trunnion 5, the end of the barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com