Rapid turning machining technology method of rubber structural member

A technology of rubber structure and processing technology, used in turning equipment, metal processing equipment, workpieces, etc., can solve the problems of limited shape and low efficiency, achieve breakthrough limitations, improve processing efficiency, and solve problems with limited shape and low efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

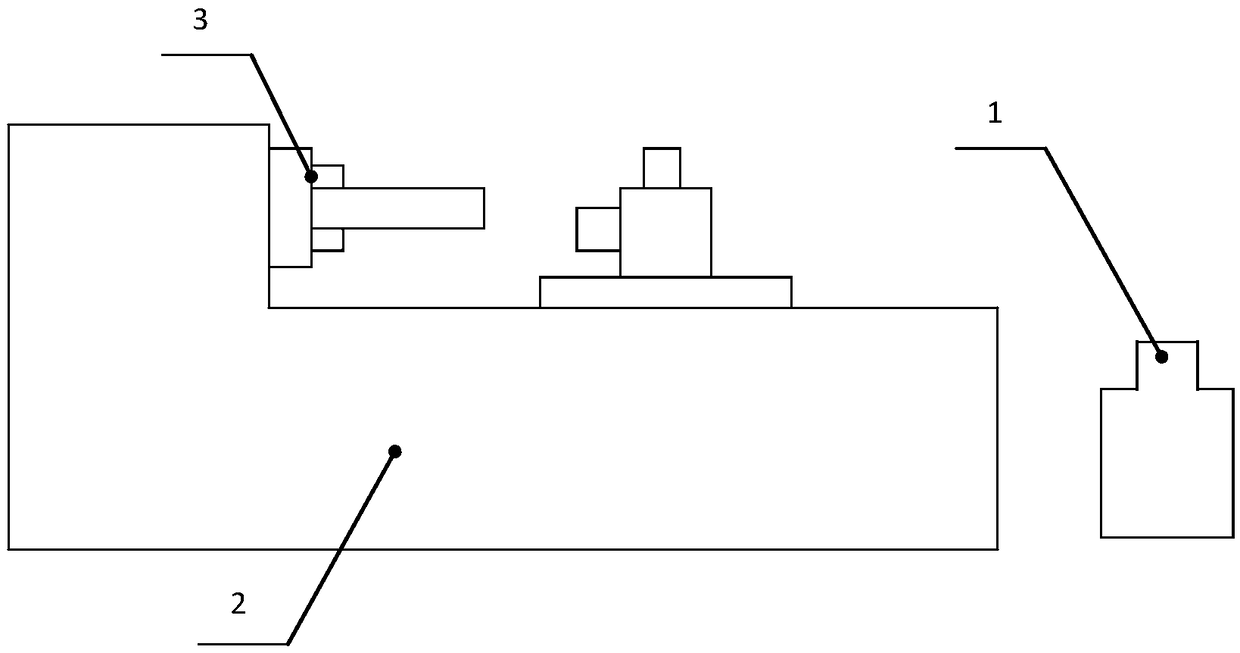

[0020] The specific steps of a rapid turning process method for rubber structural parts are:

[0021] The first step is to freeze the raw materials of the rubber structural part 6

[0022] Put the raw material 1 for processing into the rubber structural part 6 into the liquid nitrogen tank 1, and take it out after freezing for two minutes.

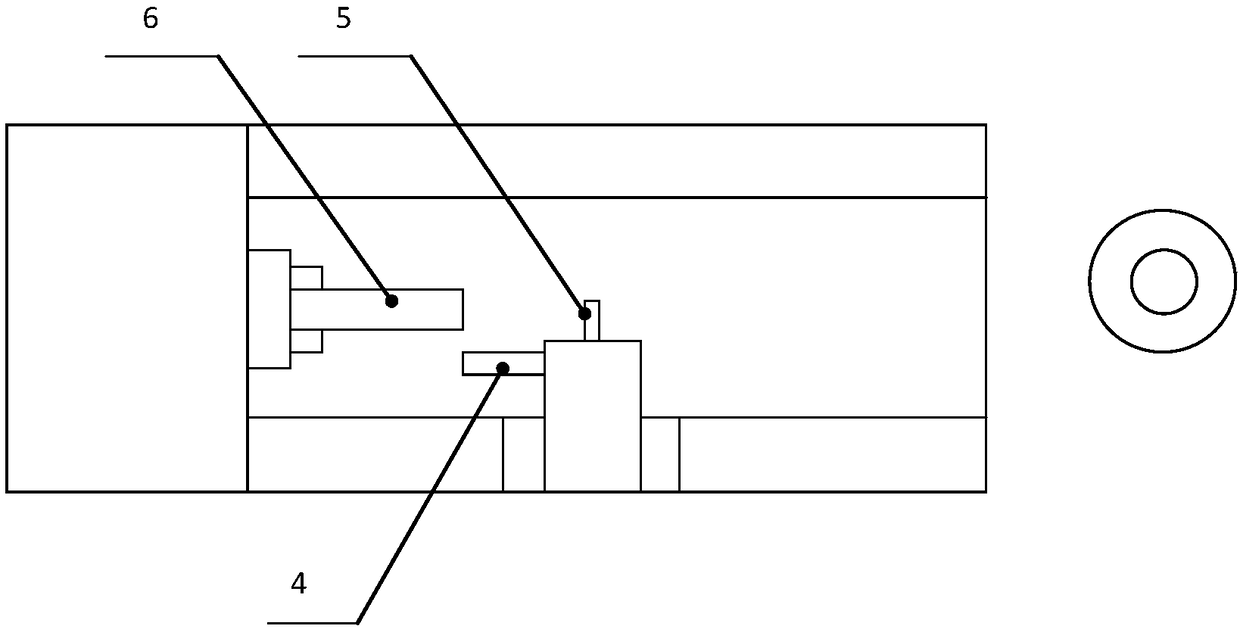

[0023] The second step is turning the raw material of the rubber structural part 6

[0024] Install the raw material of the rubber structural part 6 on the three jaws 3 of the lathe 2, turn on the power of the machine tool, turn the raw material of the rubber structural part 6 with the turning tool 4, and process the end face, outer circle and inner hole of the rubber structural part 6.

[0025] The third step is to collect the rubber structural parts 6

[0026] Use the grooving knife 5 to cut off the raw material of the rubber structure 6, take off the rubber structure 6, turn around and re-clamp with the three claws 3, process the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com