Blower for conveying powder raw materials and manufacturing method thereof

A production method and technology of powder raw materials, which are applied to conveyors, parts of pumping devices for elastic fluids, and conveying bulk materials, etc., can solve the problem of unstable raw material movement, unstable fan pressure, and the impact of raw material purity, etc. problems, to achieve stable wind pressure, reduce existing space, and reduce loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

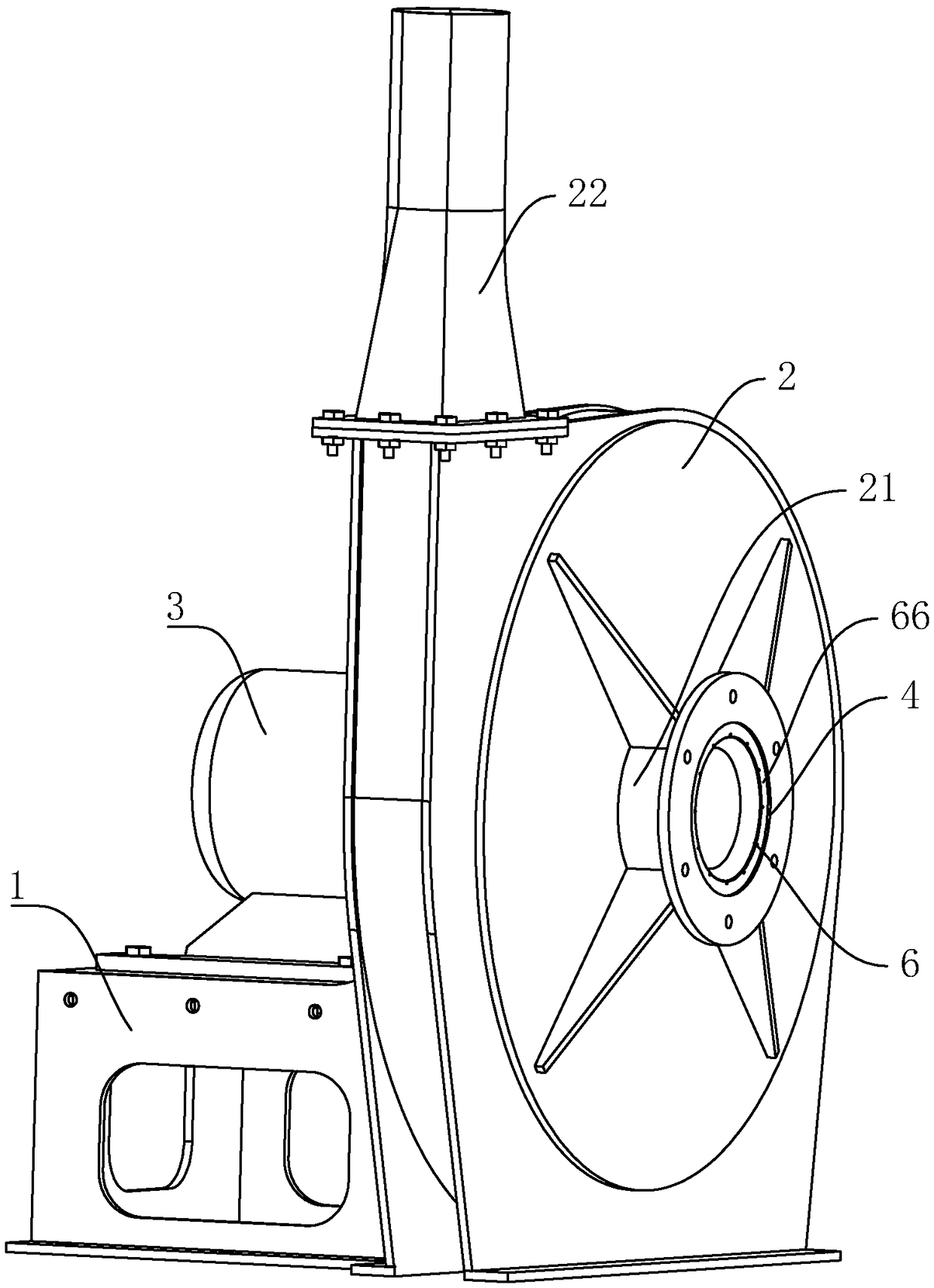

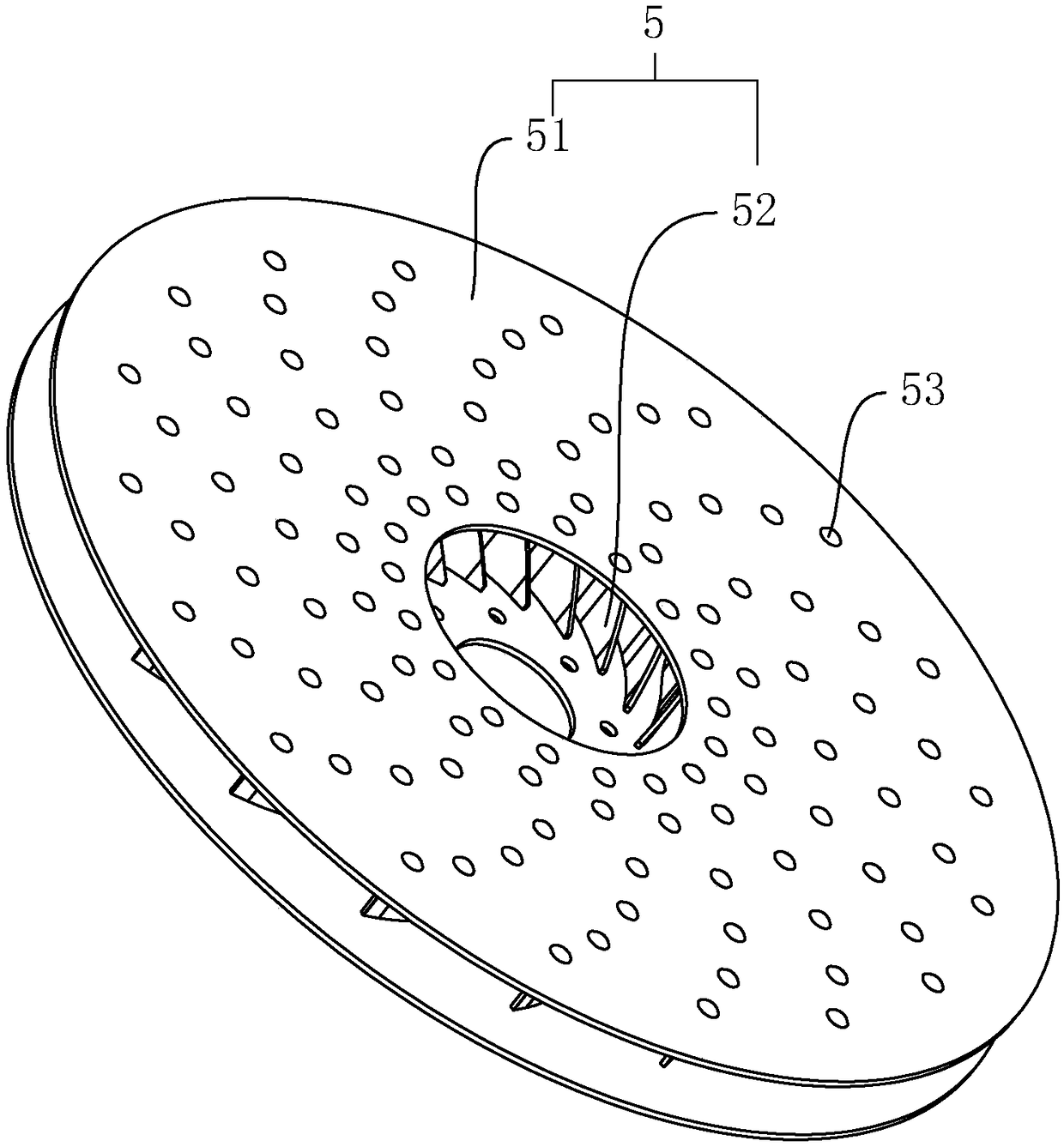

[0043] Embodiment 1: A kind of blower fan and its manufacturing method for conveying powder raw material, refer to figure 1, including a frame 1, a fan box 2, and a driving motor 3, the fan box 2 is connected to one side of the frame 1 through bolts, and the driving motor 3 is connected to the frame 1 through bolts. The output shaft of the drive motor 3 stretches into the fan box 2 and is connected with the fan impeller 5 through a key connection mode (refer to figure 2 ), the fan impeller 5 is located in the fan box 2.

[0044] refer to figure 1 , The side of the fan box 2 facing away from the frame 1 is provided with an air inlet 21 , and the top of the fan box 2 is provided with an air outlet 22 . During the working process, the drive motor 3 drives the fan impeller 5 (refer to figure 2 ) rotation, the fan impeller 5 generates a strong attractive force during the rotation process, and through the air flow guidance of the fan impeller 5, the material generates a moving ...

Embodiment 2

[0055] Embodiment 2: a kind of fan for conveying powder raw material and its manufacturing method of manufacturing method, its specific steps are as follows:

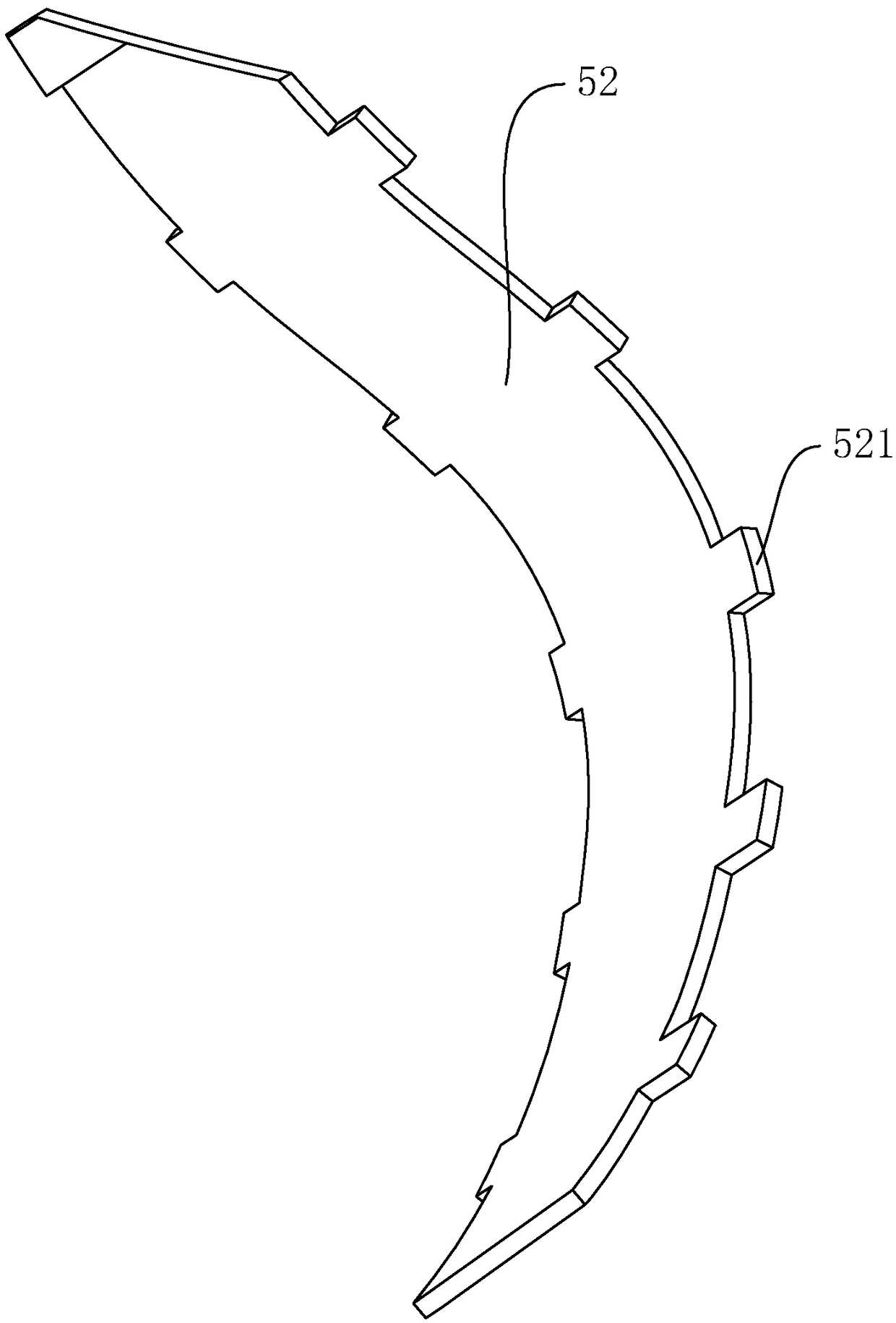

[0056] First, draw a guide line on the impeller cover 51 according to the shape of the blade 52 , and draw the opening position of the riveting hole 511 according to the position of the riveting piece 521 on the blade 52 . Then, according to the drawn position of the riveting hole 511, the staff uses a punch to punch out the riveting hole 511, and at the same time, the two sides of the riveting hole 511 are smoothed with sandpaper. Take out an impeller cover 51 and put it on the installation platform, insert the riveting piece 521 on the blade 52 into the riveting hole 511, and bend the riveting piece 521 at the same time, so that the riveting piece 521 is pressed on the impeller cover 51.

[0057] Weld the position where the riveting piece 521 is in contact with the impeller cover 51, then fill and weld the gap between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com