Injection molding equipment with hot nozzle twice ejection-free structure hot nozzle die

A technology without ejection and structural heat, applied in the field of injection mold mechanism design, it can solve the problems of difficult fully automated production, no obvious traces, and high appearance requirements, shortening the production cycle, reducing the production of nozzle materials and appearance. demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

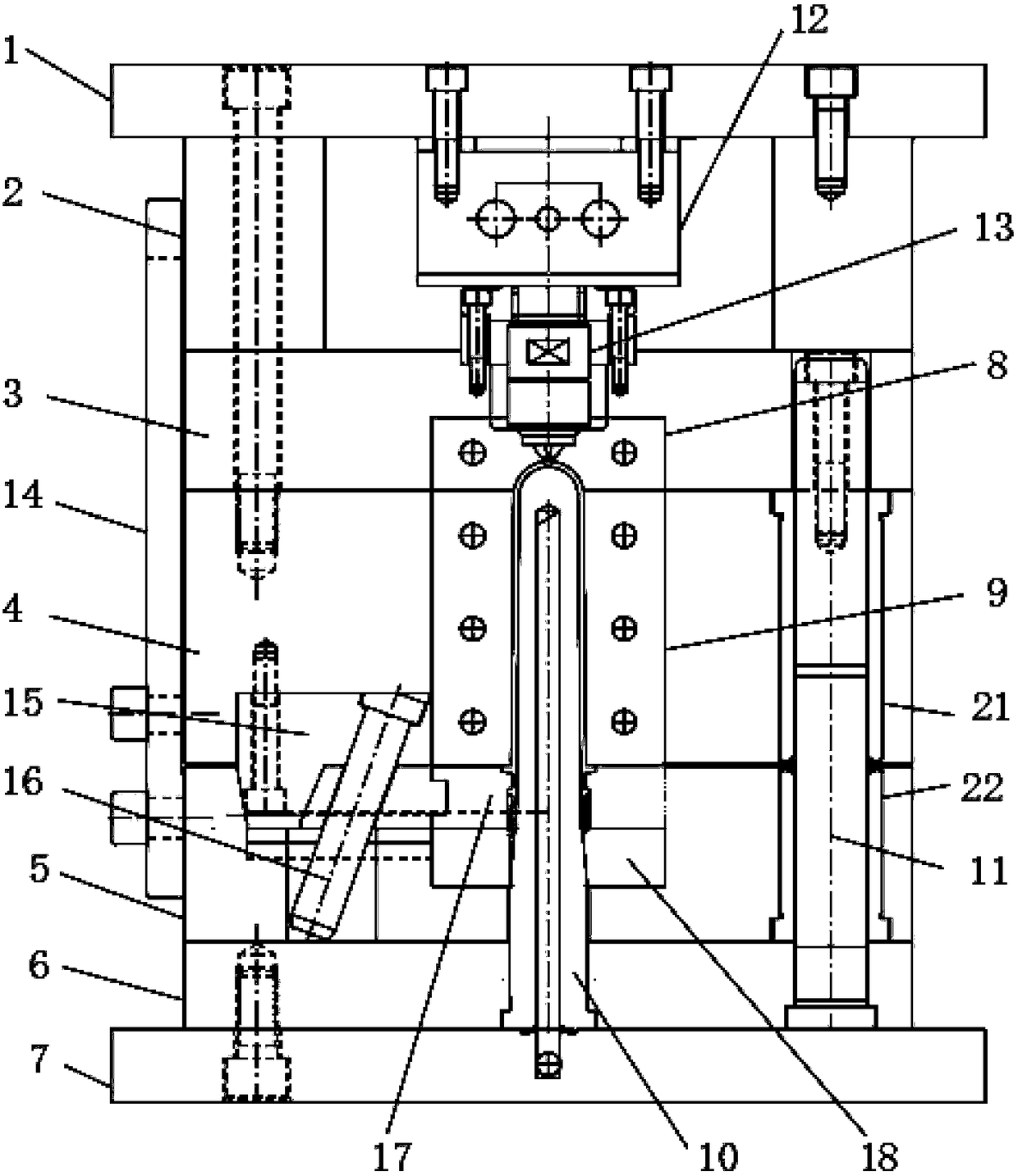

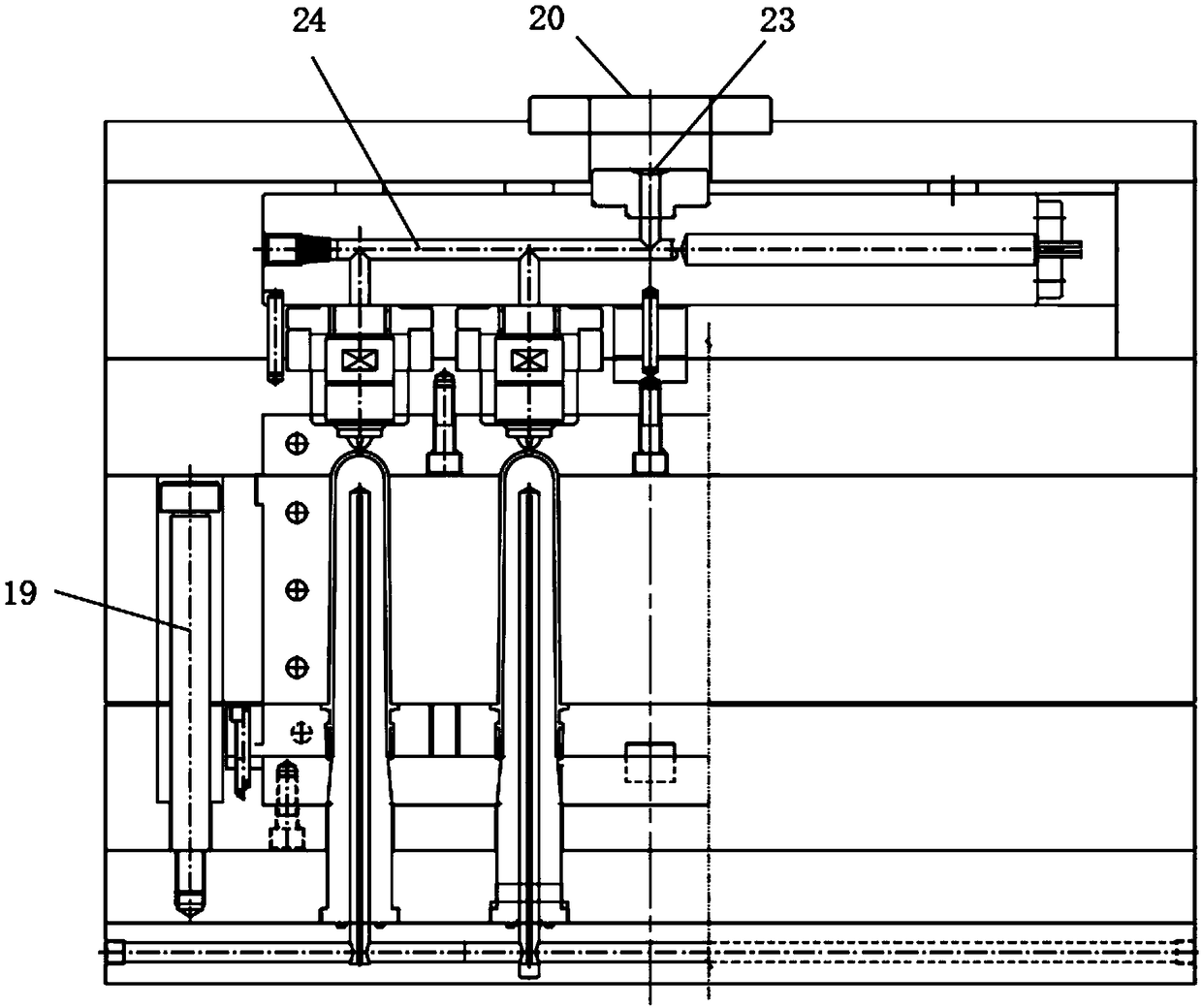

[0013] Figure 1-2 Shown is the relevant explanatory figure of the present invention; The specific embodiment is, as figure 1 , figure 2 As shown, a hot nozzle mold with double ejection structure, including a panel 1, a runner plate 2, a first fixed plate 3, a second fixed plate 4, a push plate 5, a core fixed plate 6, and a bottom plate 7 , the first fixed mold core 8, the second fixed mold core 9, the movable mold core 10, the mold guide pillar 11, the diverter plate 12, the hot nozzle 13, the limit puller 14, the shovel chicken 15, the inclined guide pillar 16, the sliding Block 17, push plate insert 18, limit pull bar 19, positioning ring 20, second fixed mold guide sleeve 21, push plate guide sleeve 22, sprue cover 23, hot runner 24.

[0014] The mold runner assembly includes a sprue sleeve 23, a positioning ring 20, a runner plate 2, a manifold 12, a hot runner 24, and a hot nozzle 13, and the sprue sleeve 23 is fastened on the panel 1 by screws for The molten plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com