Beam feeding method suitable for small-curve-radius girder erection

A technology of small radius curve and beam feeding, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems such as the inability to meet the working conditions of ultra-small radius prefabricated bridge structures, and achieve good results, convenient operation, and equipment. low cost construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

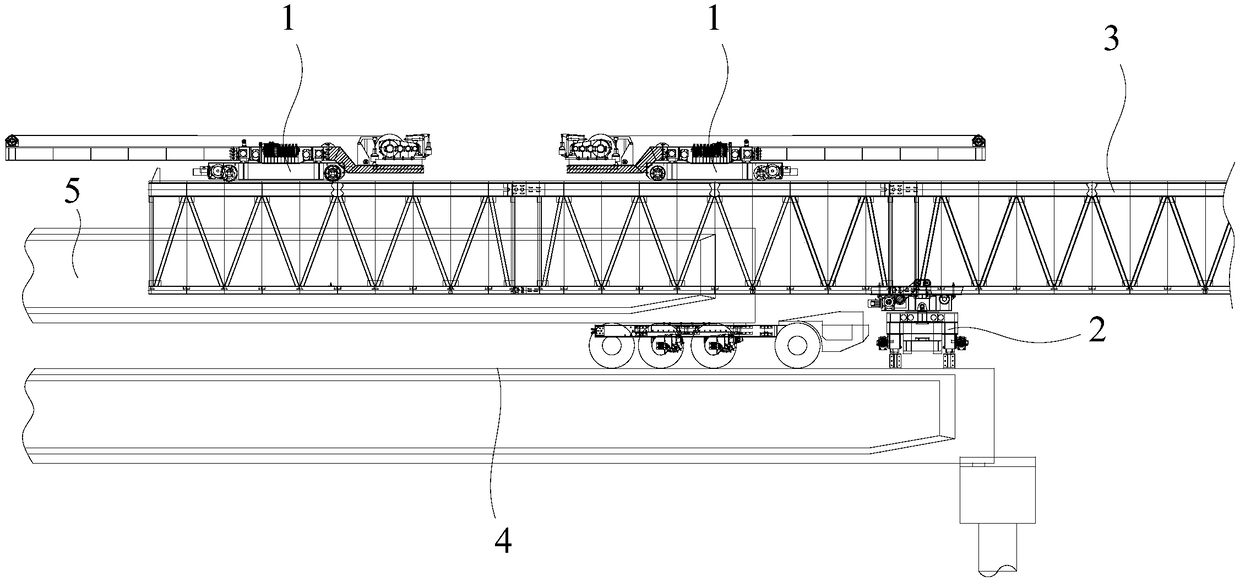

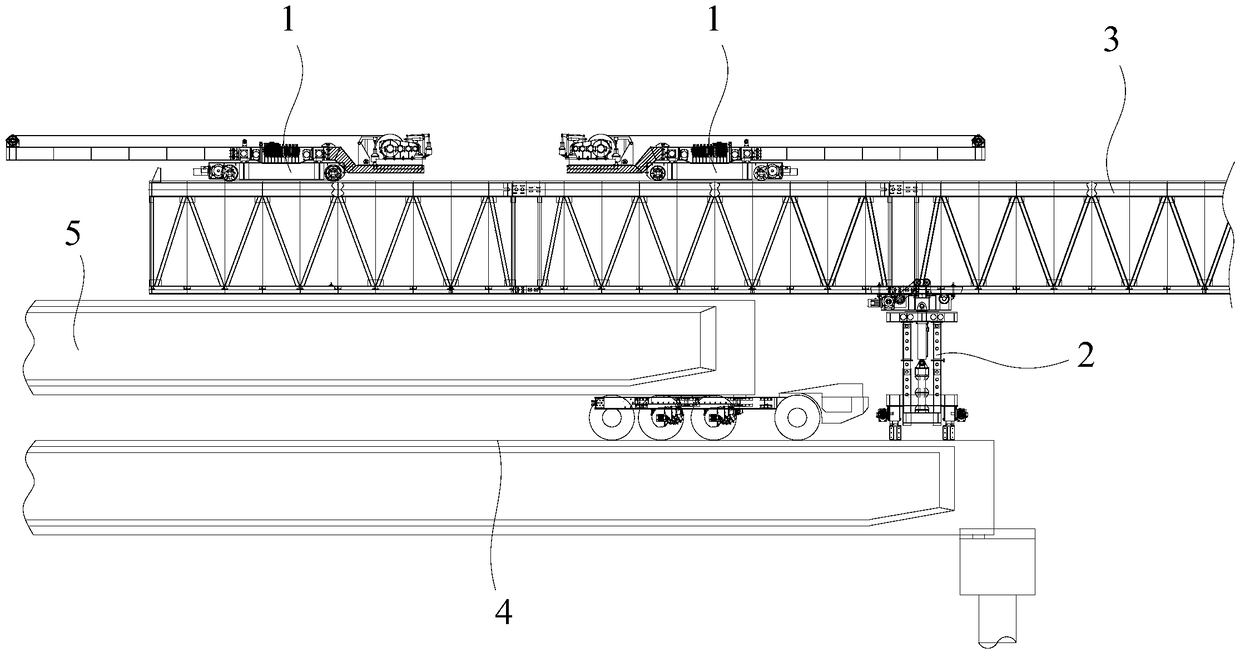

[0032] Such as Figure 1-2 As shown, a kind of beam feeding method suitable for small-radius curved girders according to the present invention comprises the following steps:

[0033] A. The double guide girder bridge erecting machine is in place, and the beam transport vehicle transports the beam part 5 to be erected on the bridge deck 4 to the area between the two main beams 3 at the end of the bridge erecting machine;

[0034] B. Lifting the front main legs and rear main legs 2 of the bridge erecting machine makes the main girder 3 rise relative to the bridge deck 4, and the distance from the bottom of the main girder 3 to the bridge deck 4 satisfies the beam to be erected Part 5 cross bridge to transport clearance;

[0035] C. The two hoisting trolleys 1 of the bridge erecting machine hoist the beam portion 5 to be erected, and there is a gap between the top of the beam portion 5 to be erected and the bottom of the main beam 3;

[0036] D. One of the hoisting carts 1 lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com