RG rotary guider and using method thereof

A guider and anti-rotation pin technology, applied in drilling equipment and methods, directional drilling, earth-moving drilling, etc., to achieve the effect of ensuring tool life, simple and fast use, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

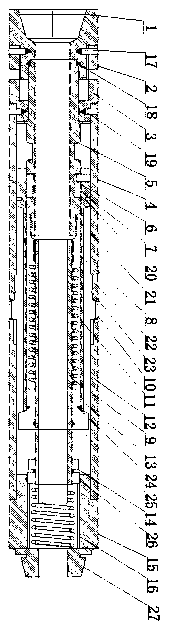

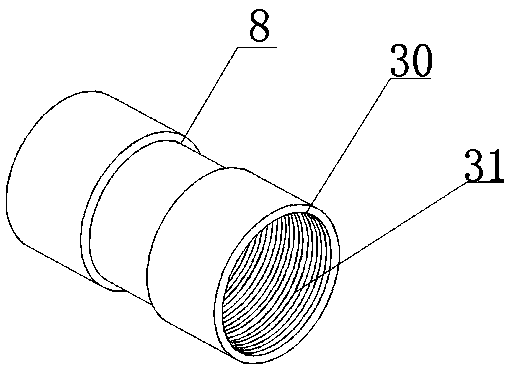

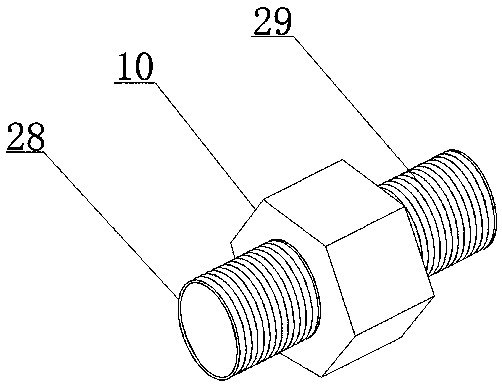

[0023] This RG rotary guide includes a rotary guide body, the rotary guide body includes a joint, a seal, a spring, a transposition mandrel 5, a splined piston 13 and a splined outer cylinder 12, and the joint includes an upper joint 1 and the lower joint 15, the seal includes a sealing outer cylinder 4, the spring includes an upper spring 11 and a lower spring 16, one end of the transposition mandrel 5 is fixedly connected to the upper joint 1, and the transposition mandrel 5 is connected to the upper A first O-ring 18 is connected between the joints 1, a double female joint 8 is connected to the other end of the transposition mandrel 5, and a third O-ring 18 is connected between the transposition mandrel 5 and the double female joint 8. O-ring 21, the lower mandrel 9 is connected to the right end of the double female joint 8, the fourth O-ring 22 is connected between the lower mandrel 9 and the double female joint 8, the right end of the lower mandrel 9 A pressure transmissi...

Embodiment 2

[0024] Embodiment 2: On the basis of Embodiment 1, the sealing outer cylinder 4 is a hollow cylindrical structure, and the inner upper spring 11 protects the lower mandrel 9 through the above structure.

Embodiment 3

[0025] Embodiment 3: On the basis of Embodiment 1, the number of anti-rotation pin 1 17 and anti-rotation pin 2 19 is 2, and the anti-rotation pin 1 17 is symmetrically distributed in the connection between the upper joint 1 and the uploading twist sleeve 2 The anti-rotation pins 2 19 are symmetrically distributed at the junction of the lower transmission twist sleeve 2 and the sealing outer cylinder 4, so as to ensure normal operation during use and effectively improve work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com