Fracturing gas production wellhead device

A wellhead device and fracturing technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of high potential risk and easy leakage, etc., and achieve convenient operation, simplified operation steps and high safety. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

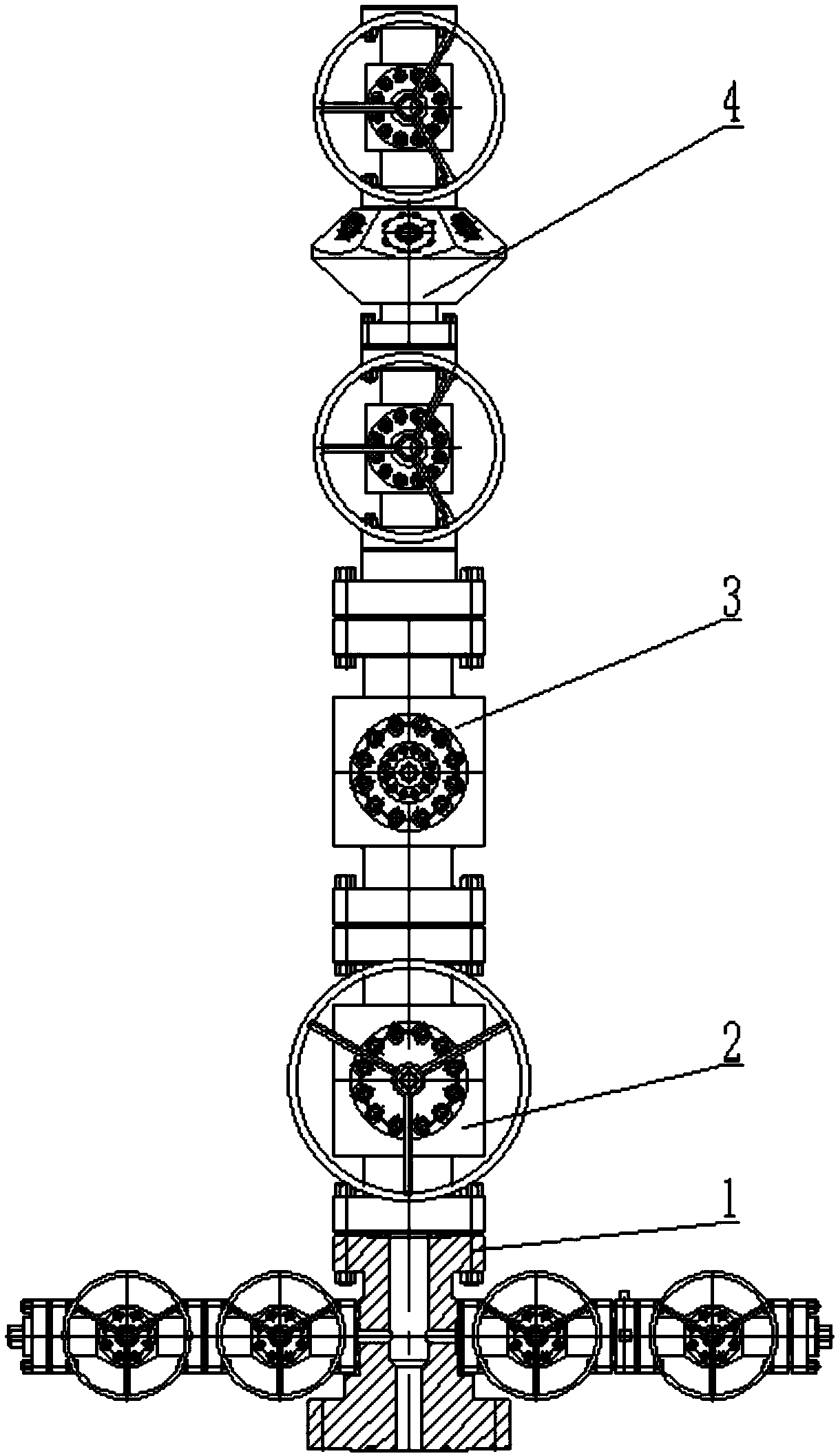

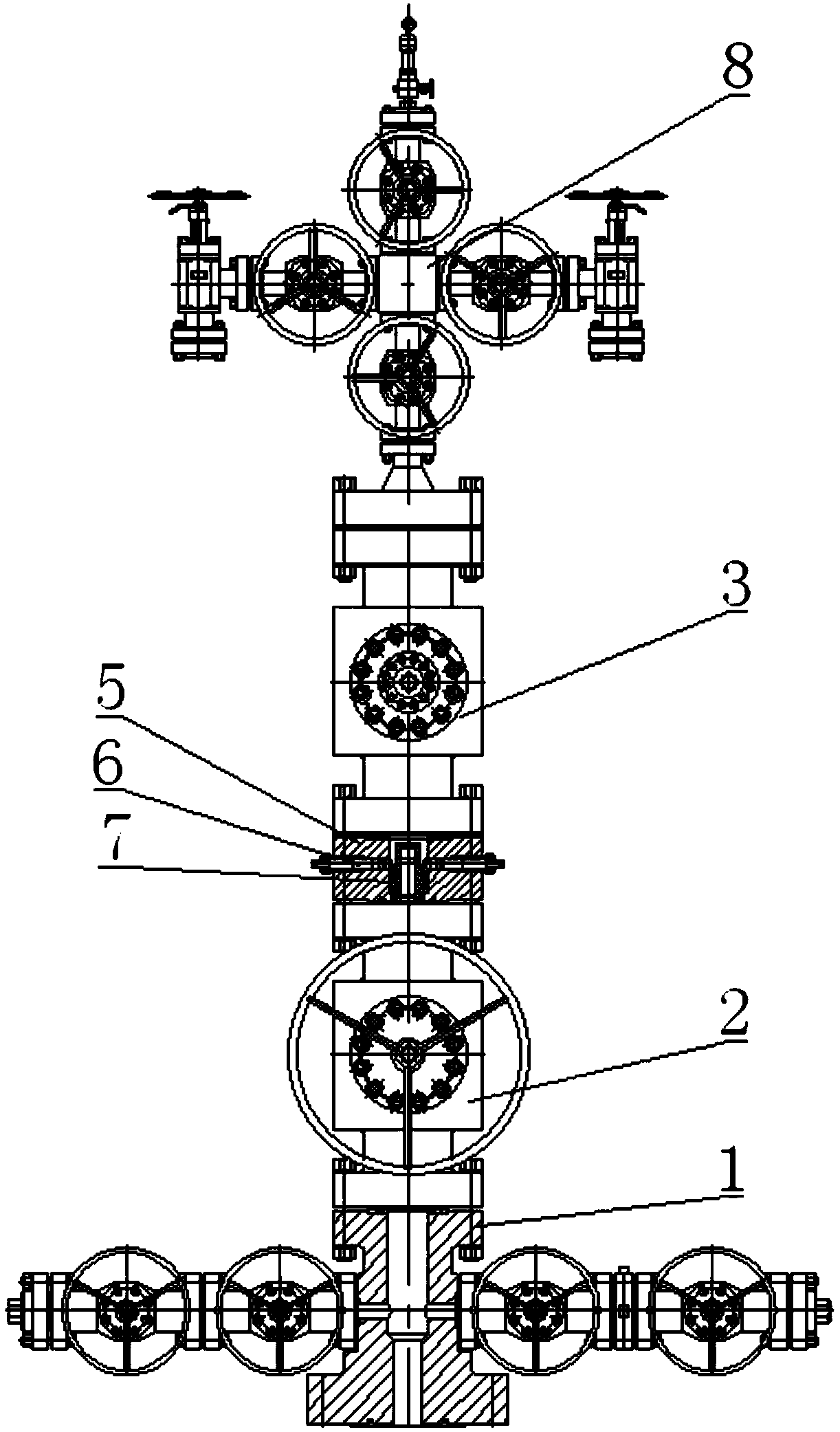

[0010] Such as figure 1 , figure 2 As shown, a fracturing gas production wellhead device includes a tubing head assembly 1; it also includes a fracturing device and a gas production device, and the fracturing device includes a main valve I2 that can be connected to the upper end of the tubing head The main valve II3 at the upper end of the valve I2 is connected to the fracturing tree 4 at the upper end of the main valve II3;

[0011] The fracturing device is installed on the tubing head assembly 1 under fracturing conditions, and the fracturing device is not connected to the suspension flange and jack wire, which greatly improves the sealing reliability of the fracturing channel, completely eliminates the hidden danger of jack wire leakage, and improves the Operating efficiency and service life of jackscrew seals.

[0012] The gas production device includes a main valve I2 that can be connected to the upper end of the tubing head assembly 1, a suspension flange 5 that is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com