Diesel engine closed-cylinder circulation system

A circulatory system, diesel engine technology, applied in mechanical equipment, engine control, machine/engine, etc., can solve the problem that the load rate of the main engine of the ship is not so high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

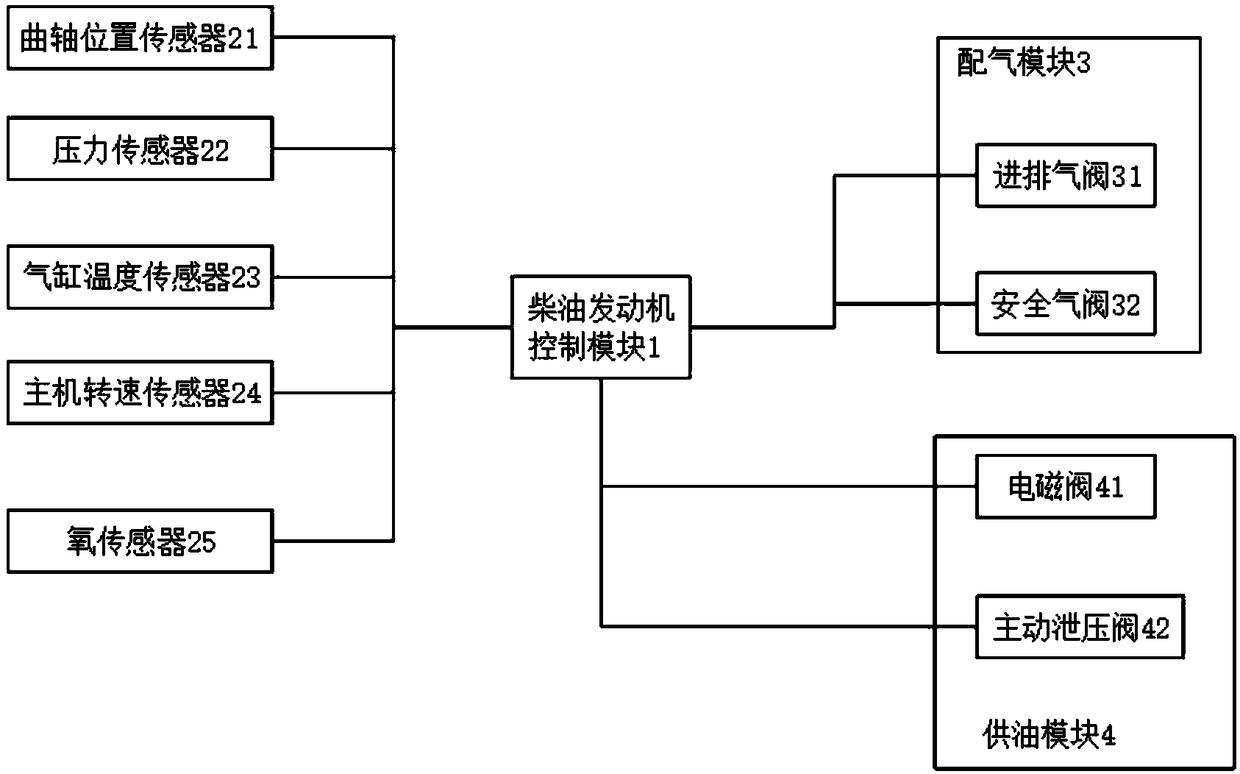

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0021] The invention provides a diesel engine cylinder closed cycle system, whose working principle is to replace the mechanical camshaft system and its transmission mechanism to control the opening and closing of the fuel injection port and the air injection port through ECM electronic control, so as to stop the work of this cylinder, so that The other cylinders work at a higher load rate, which improves the emission performance of the fuel consumption rate of the main engine, improves the emission performance of the fuel consumption rate, realizes precise timing control of the cylinders, and improves the utilization rate of the main engine Purpose.

[0022] The present invention will be described in further detail below in conjunction with examples and specific implementatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com