Constant-pressure type centrifugal pump

A centrifugal pump and formula calculation technology, which is applied in the field of constant pressure centrifugal pumps and fire pumps for high-rise buildings, can solve the problems of high failure rate, complicated control, and many equipments, and achieve head reduction, flow head curve flatness, expansion and high efficiency zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

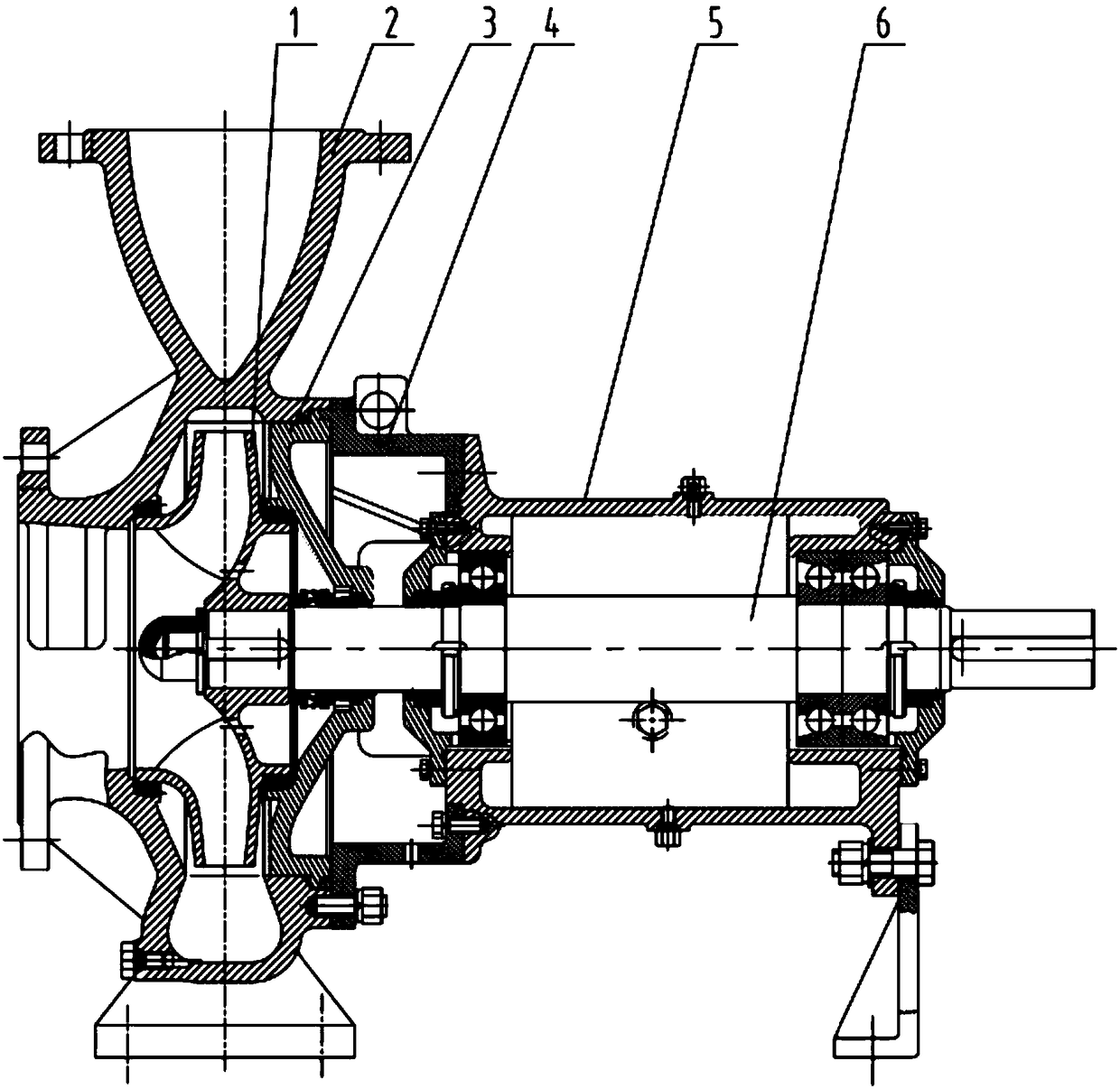

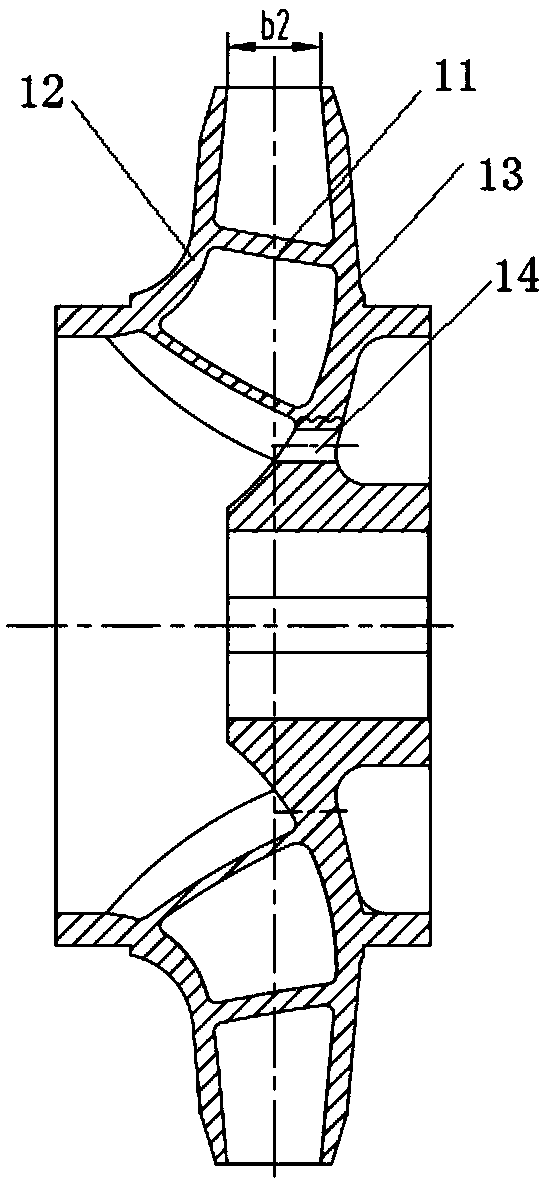

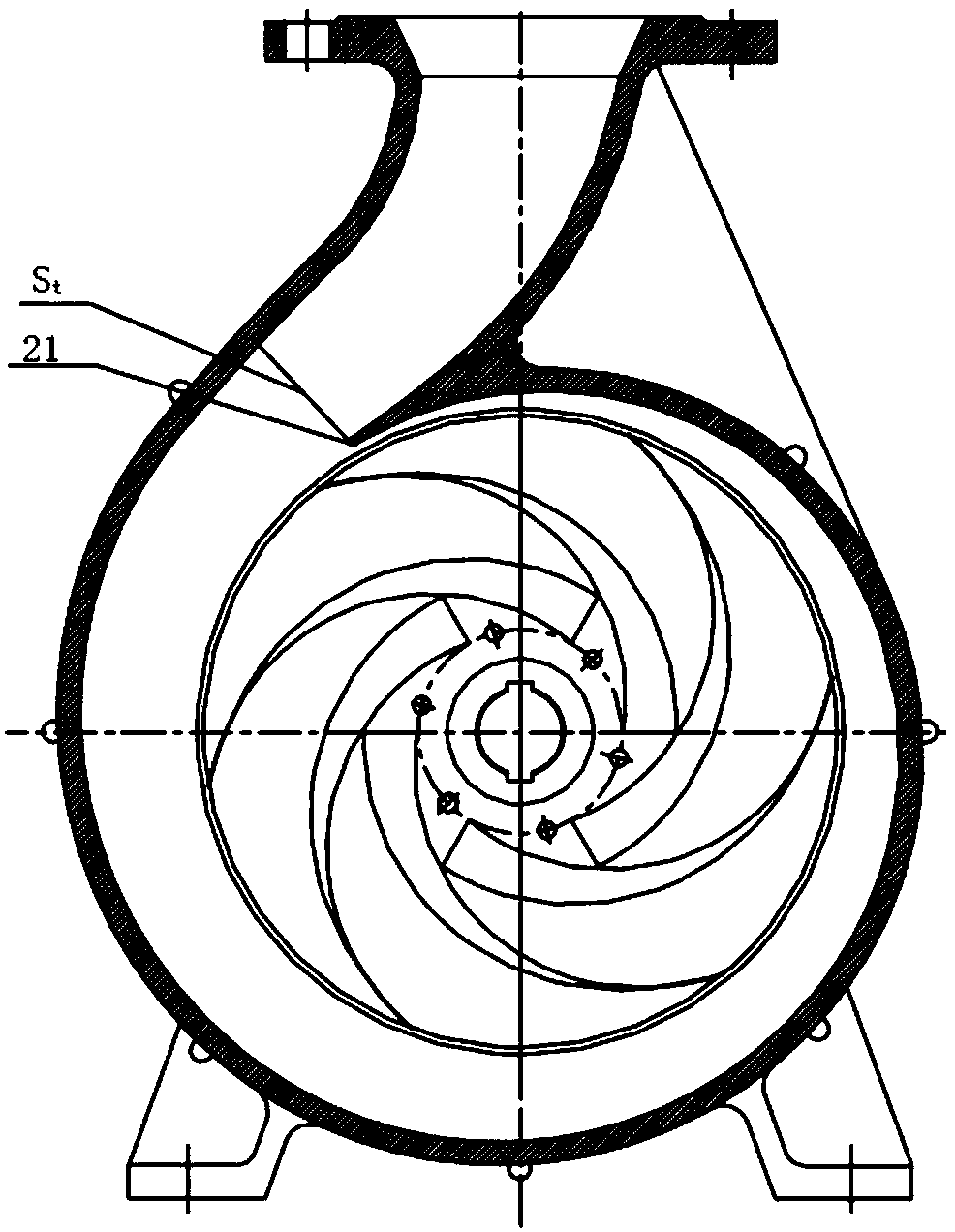

[0048] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a constant pressure centrifugal pump of the present invention includes an impeller 1, a housing 2, a seal seat 3, a bracket 4, a bearing body part 5 and a main shaft 6; the impeller 1 is a centrifugal impeller, and the impeller in this embodiment The impeller 1 is a closed impeller, and the center of one side of the impeller 1 has an impeller axial water inlet coaxial with the impeller 1. The impeller 1 is installed on the main shaft 6 and is located in the casing 2. The impeller 1 and the drive shaft of the centrifugal pump Connected by a coupling; the shell 2 is a spiral shell structure, the spiral shell structure is composed of a spiral flow channel and a diffuser tube with a gradually increasing cross-sectional area, the impeller 1 is installed in the spiral flow chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com