Centrifugal pump with double-layer guide vane blades

A technology of guide vanes and centrifugal pumps, applied in the parts, pumps, pump components of pumping devices for elastic fluids, etc., can solve problems such as difficulty in meeting customer requirements, reducing pump service life, etc., to improve the whole machine. performance, extended service life, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

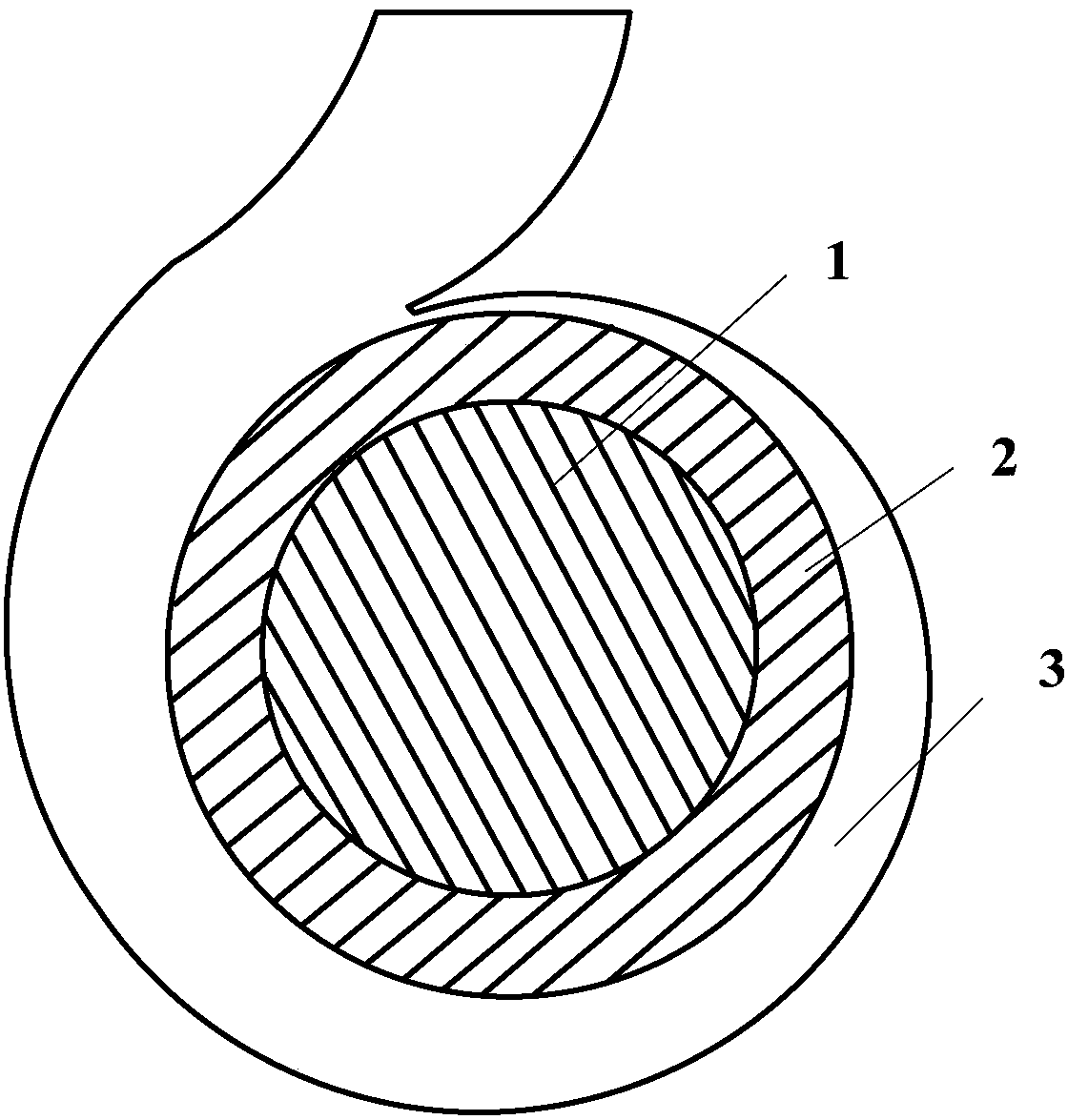

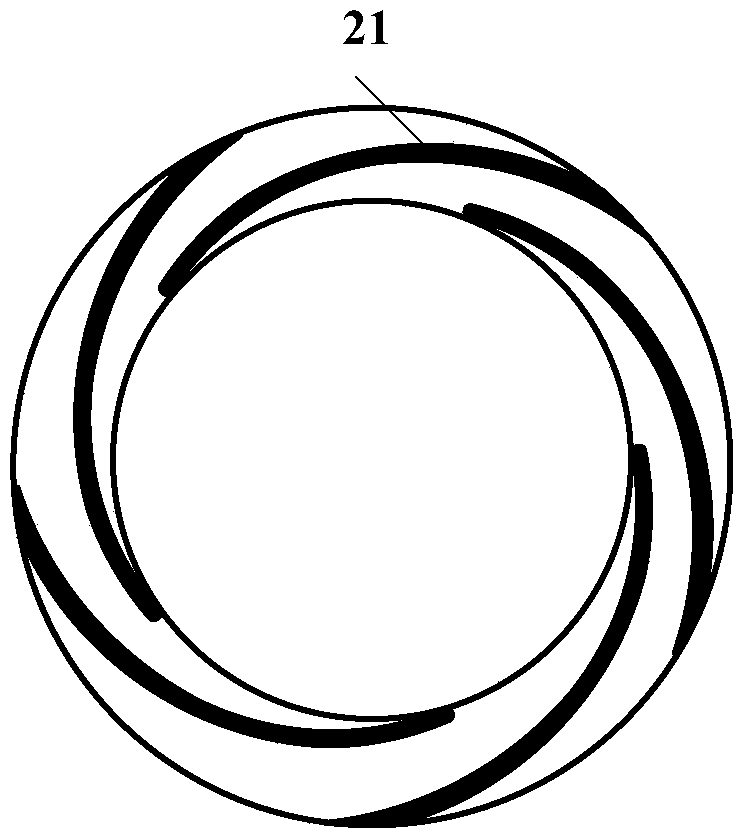

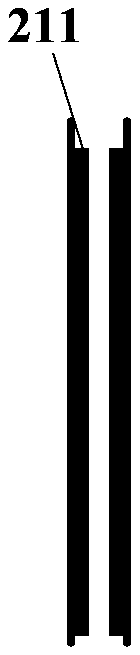

[0016] Such as figure 1 , figure 2 and image 3 As shown, a centrifugal pump using double-layer guide vane blades in the present invention is mainly composed of impeller 1, guide vane 2 and volute 3 from inside to outside, and the guide vane 2 includes several groups of double-layer guide vane blades 21; Each group of double-layer guide vane blades 21 is composed of two layers of guide vane blades 211 arranged in parallel, one layer is attached to the front cover plate of the guide vane, and the other layer is attached to the rear cover plate of the guide vane, and a certain gap is left between the two layers of guide vane blades .

[0017] As a preferred embodiment of the present invention, the number of the double-layer guide vane blades 21 is 4-8 groups.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com