A risk assessment method for rock burst in a mining area

A rock burst and dangerous technology, applied in the field of mining engineering, can solve the problems of overlying coal pillars and many small kilns, complex mining relations, shallow rock burst occurrence location, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

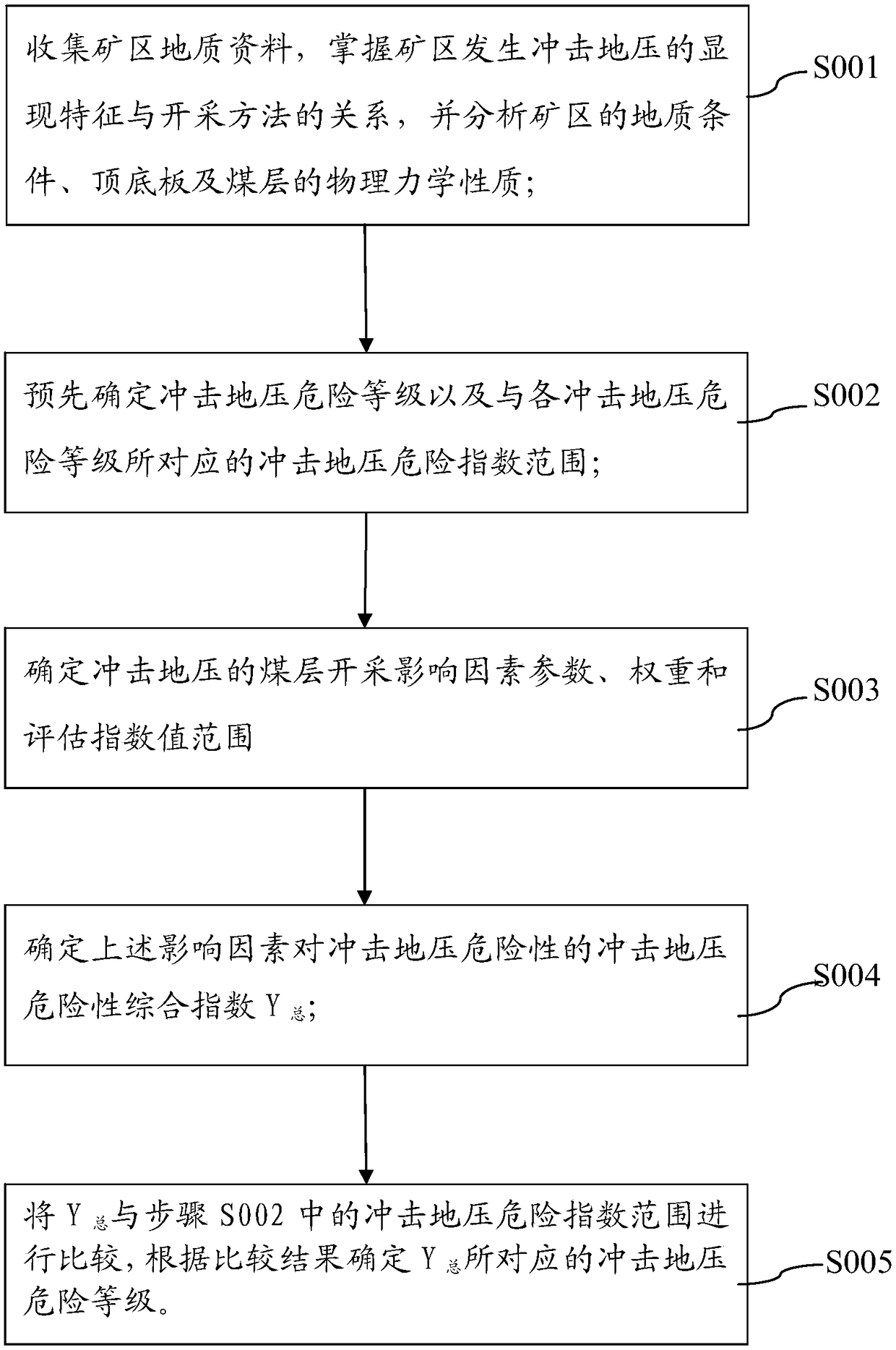

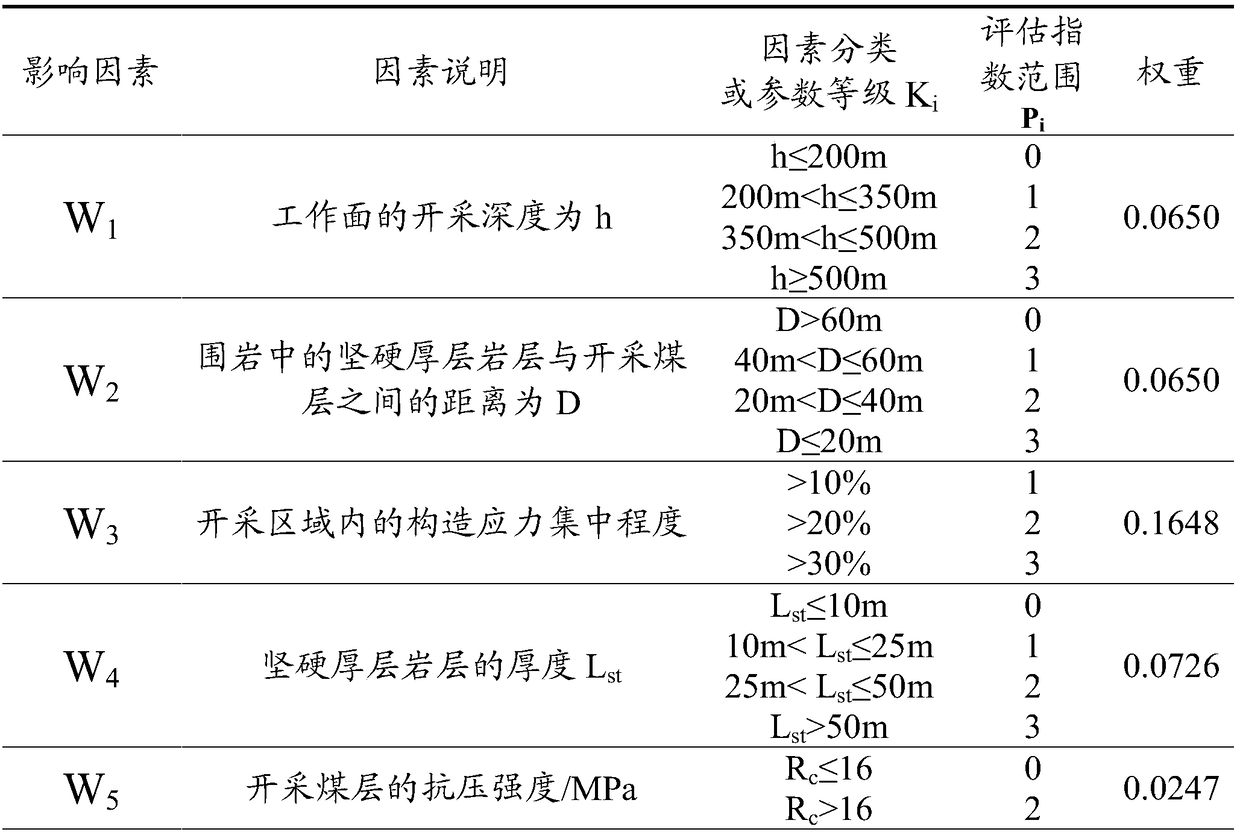

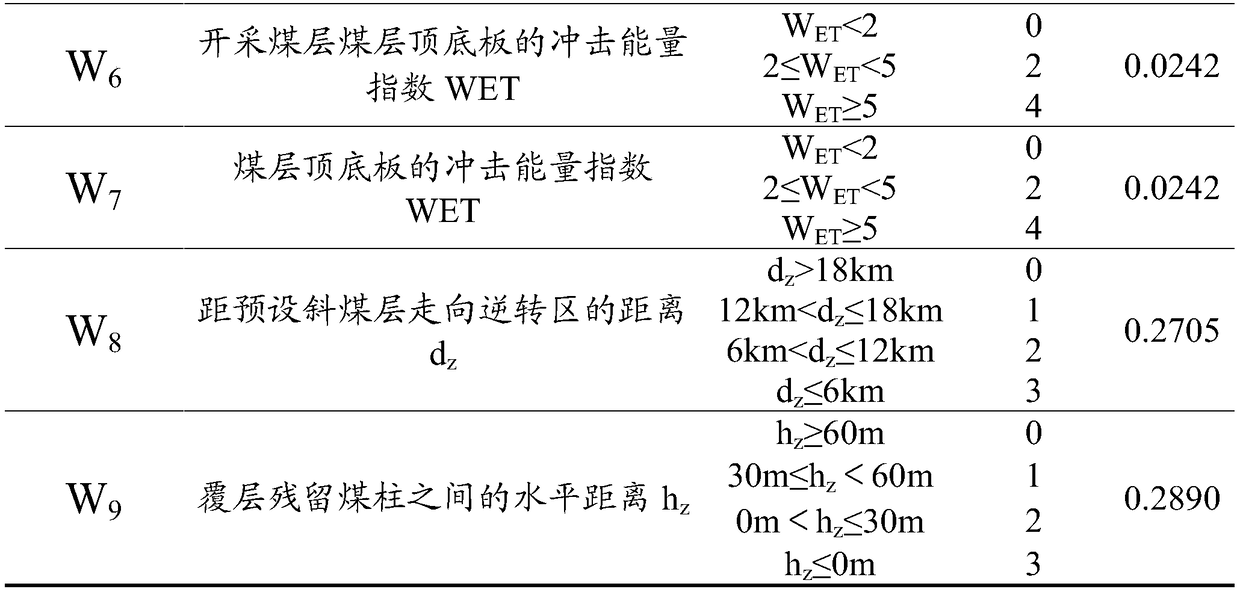

Method used

Image

Examples

Embodiment 1

[0176] Jiangou Coal Mine +469m horizontal east wing B3-6 working face has a strike length of 1871m, a working face width of 50m, a section height of 24m, a coal seam inclination of 87°, and a buried depth of about 330m. The distance between the rock layer and the coal seam is within 10m, the thickness of the roof is 23m, and the thickness of the floor is 21m. The distance within the Badaowan syncline is 13km to 15km, and the area of 798m to 947m in the working face is the overburden residual coal pillar.

[0177] Adopt the risk assessment method of mine area rock burst provided by the present invention, set up a model and carry out the risk assessment of rock burst to this working face, calculate and draw Y in the normal mining area 总 =0.36, it is the risk of weak impact, when the working face enters into the overburden residual coal pillar, Y 总 = 0.64, which is a medium impact risk.

[0178] Through the event analysis of the microseismic monitoring system, the working fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com