Monascus fermented antifatigue oat and buckwheat and preparation method thereof

An anti-fatigue and monascus technology, applied in the field of anti-fatigue nutritional products, can solve the problems of low added value and lack of nutrient elements, and achieve the effects of diverse functional components, improving health problems and obvious effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

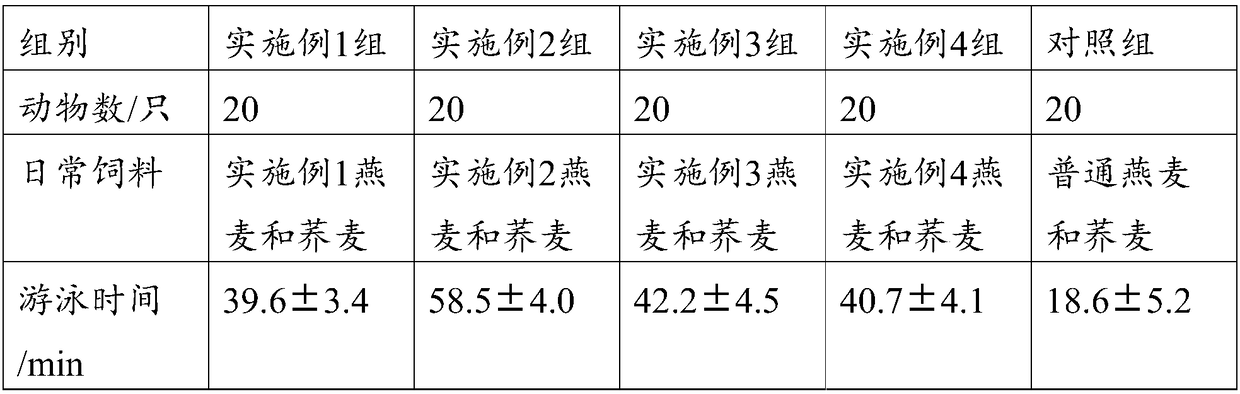

Examples

preparation example Construction

[0034] The invention provides a preparation method of anti-fatigue oats and buckwheat fermented by Monascus, comprising:

[0035] 1. Mix oats and buckwheat according to the addition ratio of (50-90): (10-50), and perform high-pressure cooking or sterilization;

[0036] Preferably, oats and buckwheat are mixed according to the addition ratio of (60-90):(10-40). More preferably, oats and buckwheat are mixed according to the addition ratio of (70-80):(20-30).

[0037] Specifically, oats and buckwheat can be steamed in a pressure cooker or sterilized in a production workshop, but not limited thereto. Wherein, the pressure of the high-pressure cooking or sterilization is preferably 0.1-0.3 MPa, and the time is preferably 20-40 min. More preferably, the pressure of the high-pressure cooking or sterilization is 0.1-0.2 MPa, and the time is 25-35 minutes.

[0038] The pressure of the high-pressure cooking or sterilization of the oats and buckwheat is set to 0.1-0.3 MPa, which can e...

Embodiment 1

[0059] Mix oats and buckwheat at a ratio of 50:50, and cook in a pressure cooker or sterilize in a production workshop at a pressure of 0.05MPa for 20 minutes;

[0060] Cool oats and buckwheat after autoclaving or sterilization;

[0061] The cooled oats and buckwheat were inoculated with Monascus anka YZ2002, and the inoculation amount of Monascus anka YZ2002 was 0.5%. The Monascus anka was preserved in Guangdong Province on July 30, 2018 Microbial Culture Collection Center, the biological deposit number is: GDMCC NO: 60426;

[0062] Stir the inoculated oats and buckwheat evenly, and place them in a container for aerobic fermentation. The temperature of the aerobic fermentation is 25°C, and the time is 15 days;

[0063] Drying the fermented oats and buckwheat at a temperature of 60°C for 20 hours;

[0064] Crush dried oats and buckwheat;

[0065] The crushed oats and buckwheat are packaged as required to obtain finished products.

Embodiment 2

[0067] Mix oats and buckwheat at a ratio of 60:40, and cook in a pressure cooker or sterilize in a production workshop at a pressure of 0.1 MPa for 25 minutes;

[0068] Cool oats and buckwheat after autoclaving or sterilization;

[0069] The cooled oats and buckwheat were inoculated with Monascus anka YZ2002, and the inoculation amount of Monascus anka YZ2002 was 2.0%. The Monascus anka was preserved in Guangdong Province on July 30, 2018 Microbial Culture Collection Center, the biological deposit number is: GDMCC NO: 60426;

[0070] Stir the inoculated oats and buckwheat evenly, and place them in a container for aerobic fermentation. The temperature of the aerobic fermentation is 28°C, and the time is 10 days;

[0071] Drying the fermented oats and buckwheat at a temperature of 65°C for 25 hours;

[0072] Crush dried oats and buckwheat;

[0073] The crushed oats and buckwheat are packaged as required to obtain finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com