Method for preparing liquid smoked spice and liquid smoked spice

A technology of liquid fumigation and spices, which is applied in the field of preparation of liquid fumigation spices and liquid fumigation spices. It can solve the problems of difficult recycling of fruit shells, discarding or incineration of fruit shells, waste of resources, etc., and achieve harmonious aroma, reduce pollution, and fast heating speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Select 2.5 kg of processed macadamia nut shells without any chemical treatment, remove impurities, wash, and dry to a moisture content of 5.1%.

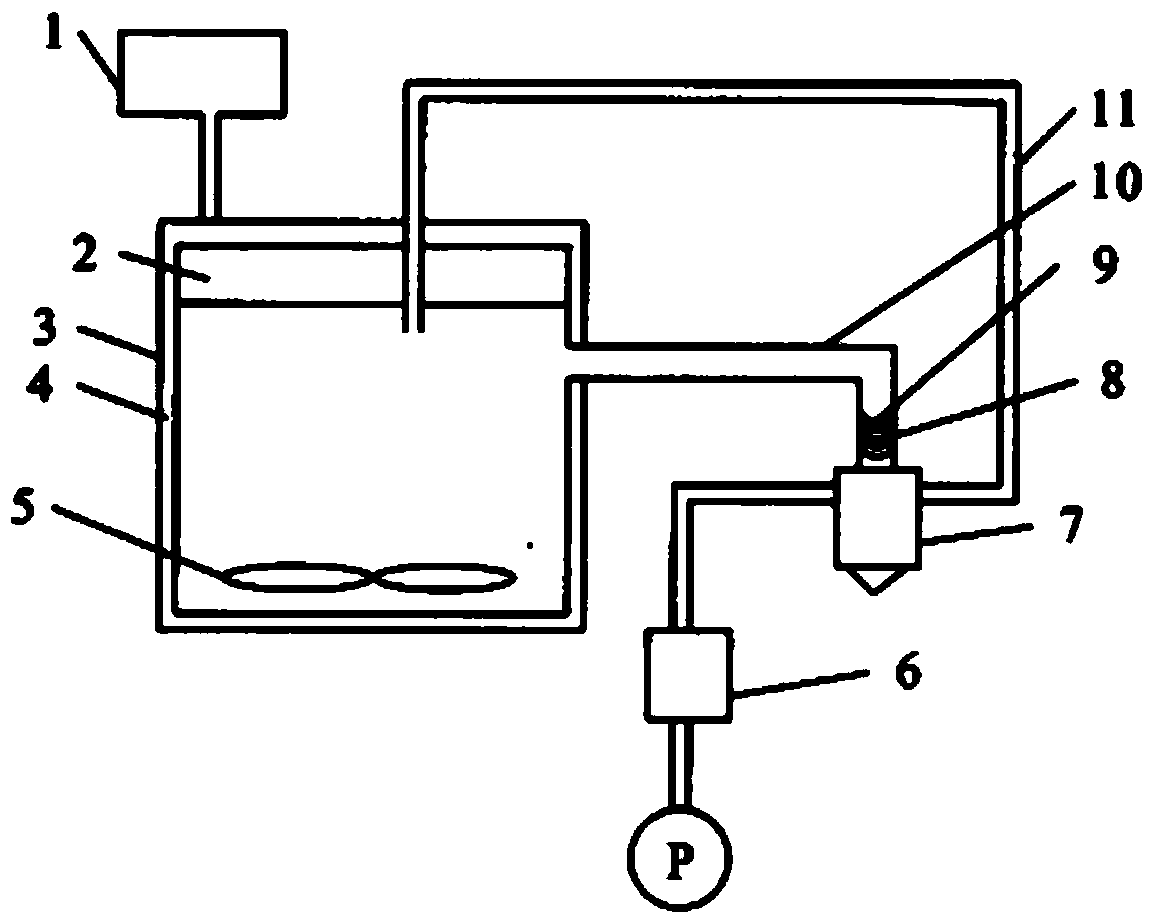

[0045] The dried macadamia nut shells are crushed, passed through a 20-mesh sieve, and placed in a microwave reaction device equipped with a condensation recovery device for microwave irradiation dry distillation. Turn on the condensed water, adjust the power to 1000W, and the microwave frequency to 2450MHz, discard the condensed recovery liquid collected in the first 5 minutes, continue heating, and collect the condensed recovered liquid after 5 minutes.

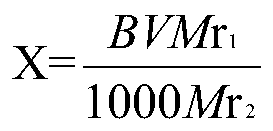

[0046] Then filter the above-mentioned condensed and recovered liquid through double-layer neutral filter paper under reduced pressure to remove impurities, distill under normal pressure, collect the first fraction at 95-115°C, re-distill the first fraction, and collect at 101-105°C The second fraction within is the initial product.

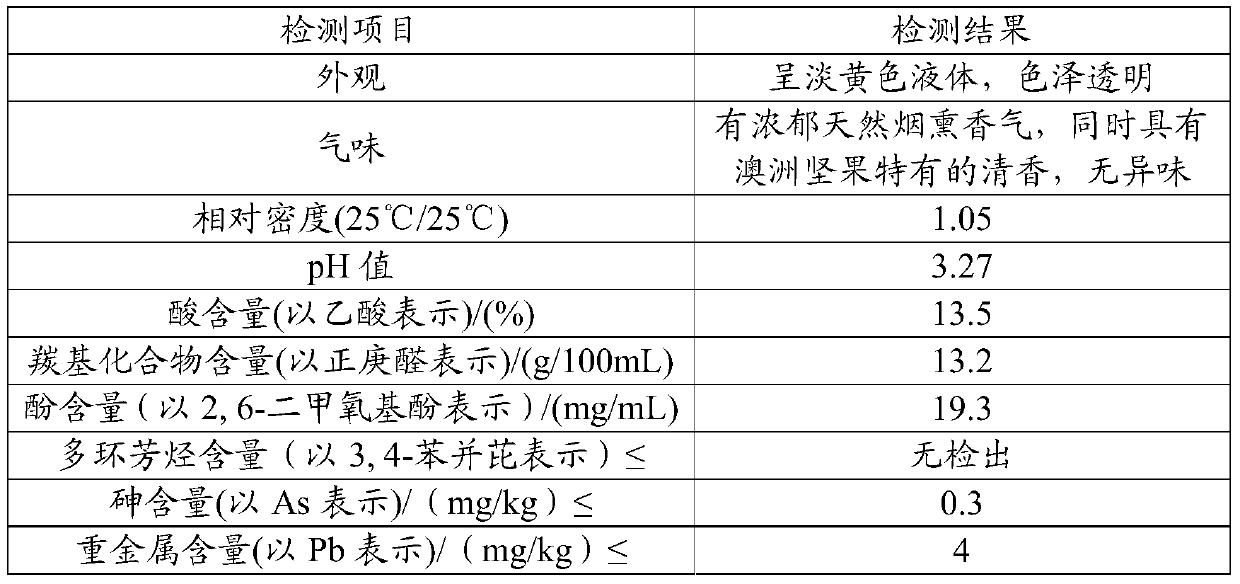

[0047] The initial product is aged at ...

Embodiment 2

[0085] Select 3 kg of macadamia nuts processed without any chemical treatment, remove impurities, wash, and dry to a moisture content of 10.2%.

[0086] The macadamia nut shells are crushed and passed through a 20-mesh sieve, and placed in a microwave reaction device equipped with a condensation recovery device for microwave irradiation dry distillation. Turn on the condensed water, adjust the power to 2000W, and the microwave frequency to 2450MHz, discard the condensed recovery liquid collected in the first 5 minutes, continue heating, and collect the condensed recovered liquid after 5 minutes.

[0087] Then filter the condensate through double-layer neutral filter paper under reduced pressure to remove impurities, then distill under normal pressure, collect the first fraction at 95-115°C, re-distill the first fraction, and collect the fraction at 101-105°C The second fraction is the initial product.

[0088] Put the initial product in a constant temperature shaker at 40°C f...

Embodiment 3

[0093] Select 3 kg of macadamia nuts processed without any chemical treatment, remove impurities, wash, and dry to a moisture content of 19.7%.

[0094] The macadamia nut shells are crushed and passed through a 20-mesh sieve, and placed in a microwave reaction device equipped with a condensation recovery device for microwave irradiation dry distillation. Turn on the condensed water, adjust the power to 1500W, and the microwave frequency to 2450MHz, discard the condensed recovery liquid collected in the first 5 minutes, continue heating, and collect the condensed recovered liquid after 5 minutes.

[0095] Then filter the condensate through double-layer neutral filter paper under reduced pressure to remove impurities, then distill under normal pressure, collect the first fraction at 95-115°C, re-distill the first fraction, and collect the fraction at 101-105°C The second fraction is the initial product.

[0096] The initial product was kept at 50°C under normal pressure for 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com