Production method of multi-flavor rice wine sauce

A production method, the technology of fragrant bittern, is applied in the field of production of multi-taste fragrant bittern, which can solve the problems of uncoordinated aroma and heavy stewed taste, and achieve the effect of typical fragrance, long aftertaste and rich aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

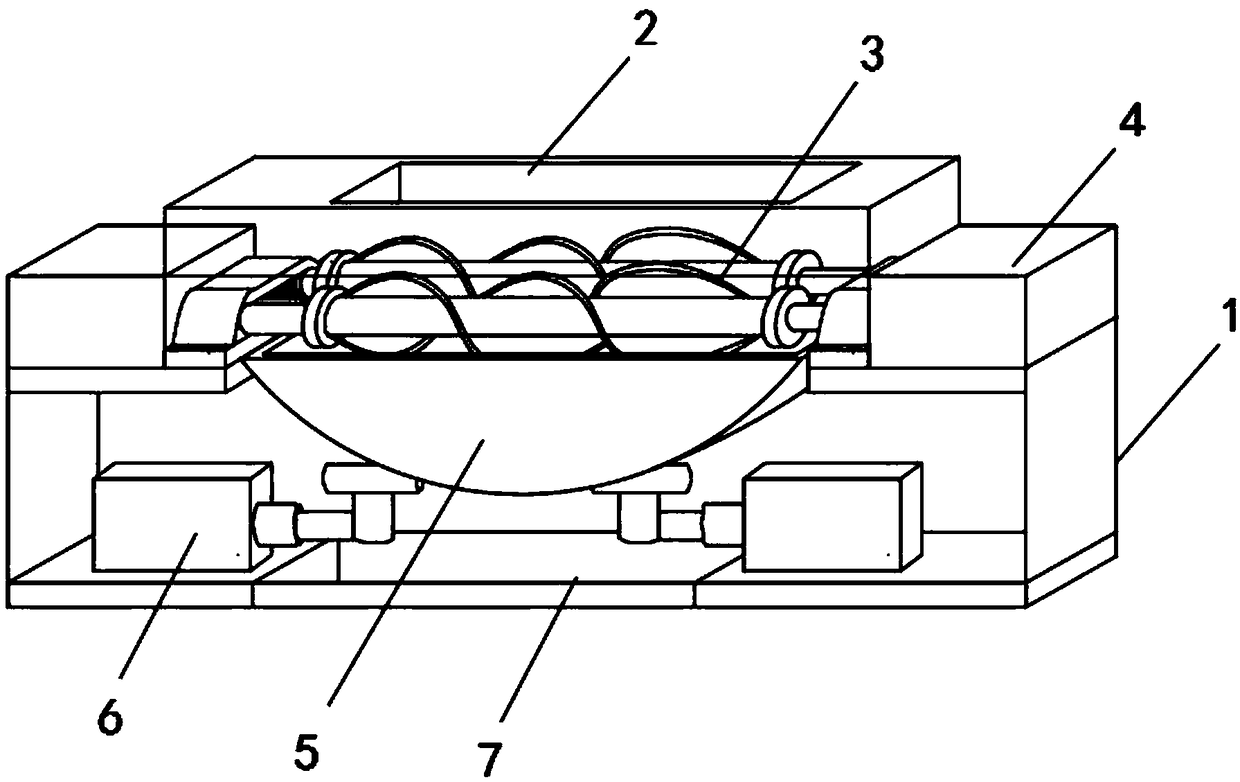

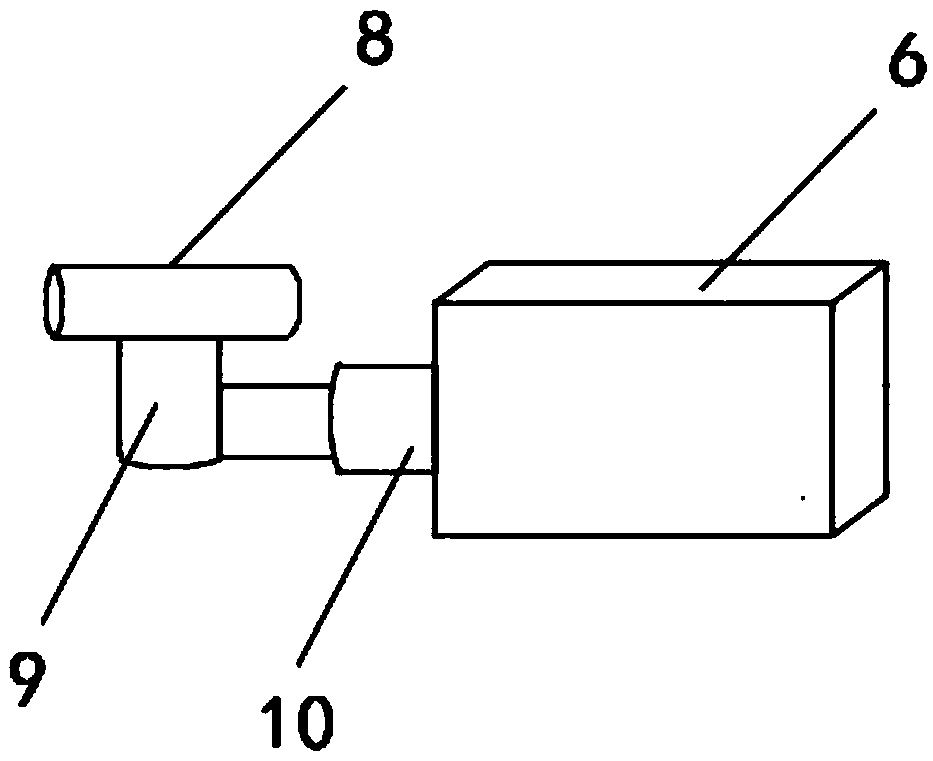

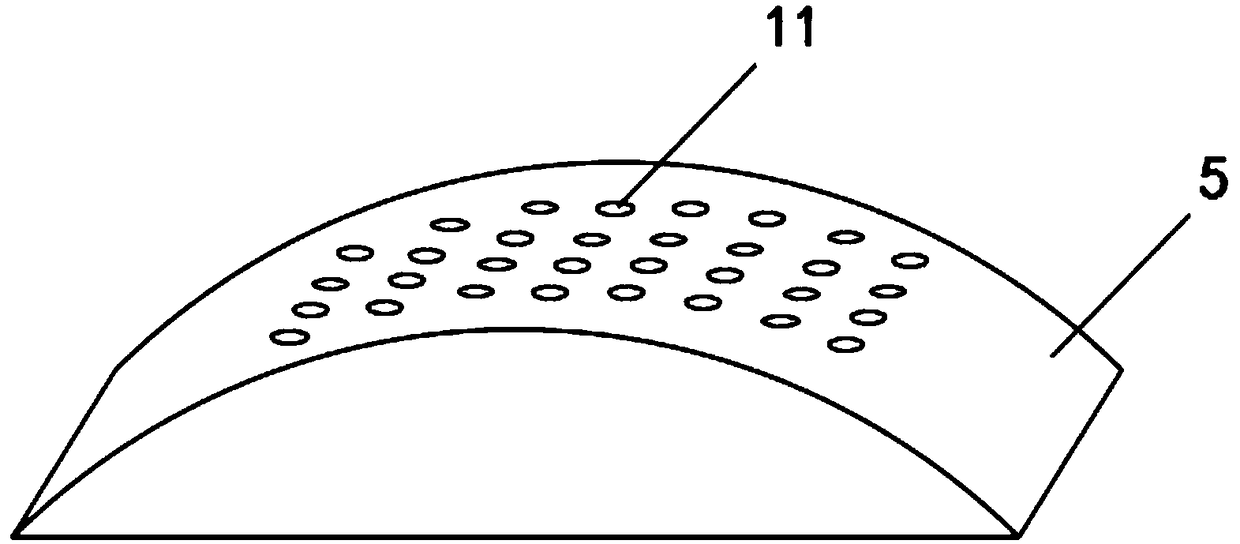

[0033] Such as Figure 1-3 Shown, a kind of production method of multi-taste fragrant grains bittern, each raw material and weight in this fragrant grains bittern are: water 105kg, fragrant grains 12-18kg, semi-dry rice wine 6%, edible salt 7-8%; Fragrant grains The raw materials and their weight are: 100kg of rice distiller's grains, 2-4kg of natural plant mixed spices; the raw materials and their weight of natural plant mixed spices are: 5-9kg of cloves, 150-190kg of tangerine peel, 24-30kg of fragrant leaves, 32- 38kg, fennel 28-35kg, Chinese prickly ash 28-35kg, licorice 18-25kg, cinnamon bark 20-26kg; as a liquid seasoning product, fragrant grains and stewed grains using this formula are rich in aroma, typical and harmonious, and taste Delicious, refreshing, long aftertaste;

[0034] The production steps of this fragrant bad bittern are:

[0035] According to the raw materials and weight ratios in the above-mentioned natural plant mixed spices, cloves, tangerine peel, b...

Embodiment 2

[0043] read on Figure 1-3 , the combination of three kinds of natural plant mixed spices is as follows:

[0044] The raw materials and weight of various natural plant spices in the light fragrance formula are: 5kg of cloves, 150kg of tangerine peel, 24kg of bay leaves, 32kg of fennel, 28kg of anise, 28kg of peppercorns, 18kg of licorice, and 20kg of cinnamon bark. People with light taste eat;

[0045] The raw materials and weight of various natural plant spices in the moderate formula are: 7kg of cloves, 170kg of tangerine peel, 27kg of bay leaves, 35kg of cumin, 31kg of anise, 32kg of pepper, 21kg of licorice, and 23kg of cinnamon.

[0046] The raw materials and weights of the natural plant mixed spices in the stew-flavor formula are: clove 9kg, tangerine peel 190kg, bay leaves 30kg, cumin 38kg, anise 35kg, pepper 35kg, licorice 25kg, cinnamon 26kg. It is suitable for people with heavy taste.

[0047] During the production process, the purpose of sealing and storing the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com