Material lifting platform

A technology for lifting platforms and materials, which is applied in the direction of lifting frames, lifting devices, lifting equipment safety devices, etc., can solve the problems that cannot meet the conditions of on-site use, and achieve the effect of convenient operation and movement for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

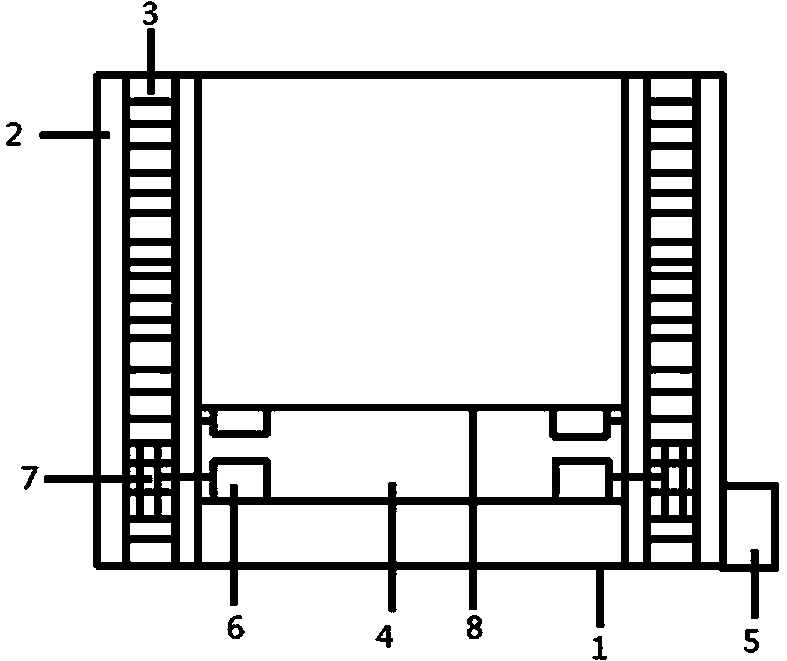

[0011] Such as figure 1 As shown, a material lifting platform of the present invention includes a bracket 1, a column 2, a gear bar 3, a lifting platform 4, and a controller 5; the bracket 1 is connected to the column 2, and the column 2 is provided with the Gear bar 3, described gear bar 3 is connected with described lifting platform 4, and described lifting platform 4 is connected with described controller 5; Described lifting platform 4 comprises motor 6, gear 7, loading platform 8; Said loading platform 8 The motor 6 is arranged at the bottom, the gear 7 is arranged on the transmission shaft of the motor 6, and the gear 7 is engaged with the gear bar 3; the motor 6 is connected with the controller 5.

[0012] In a preferred solution, protective nets are set around the load-carrying platform to prevent objects in the platform from falling from a high altitude.

[0013] In a preferred solution, the column is in a curved shape to prevent the gear rack from breaking due to ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com