Sewing machine and automatic thread trimming and presser foot lifting mechanism thereof

A thread trimming mechanism and presser foot lifting technology are applied in the thread cutting mechanism, cloth pressing mechanism, sewing machine components and other directions in a sewing machine, which can solve the problems of high manufacturing cost, large space occupation, and many parts, and achieve low manufacturing cost. , The effect of taking up less space and reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

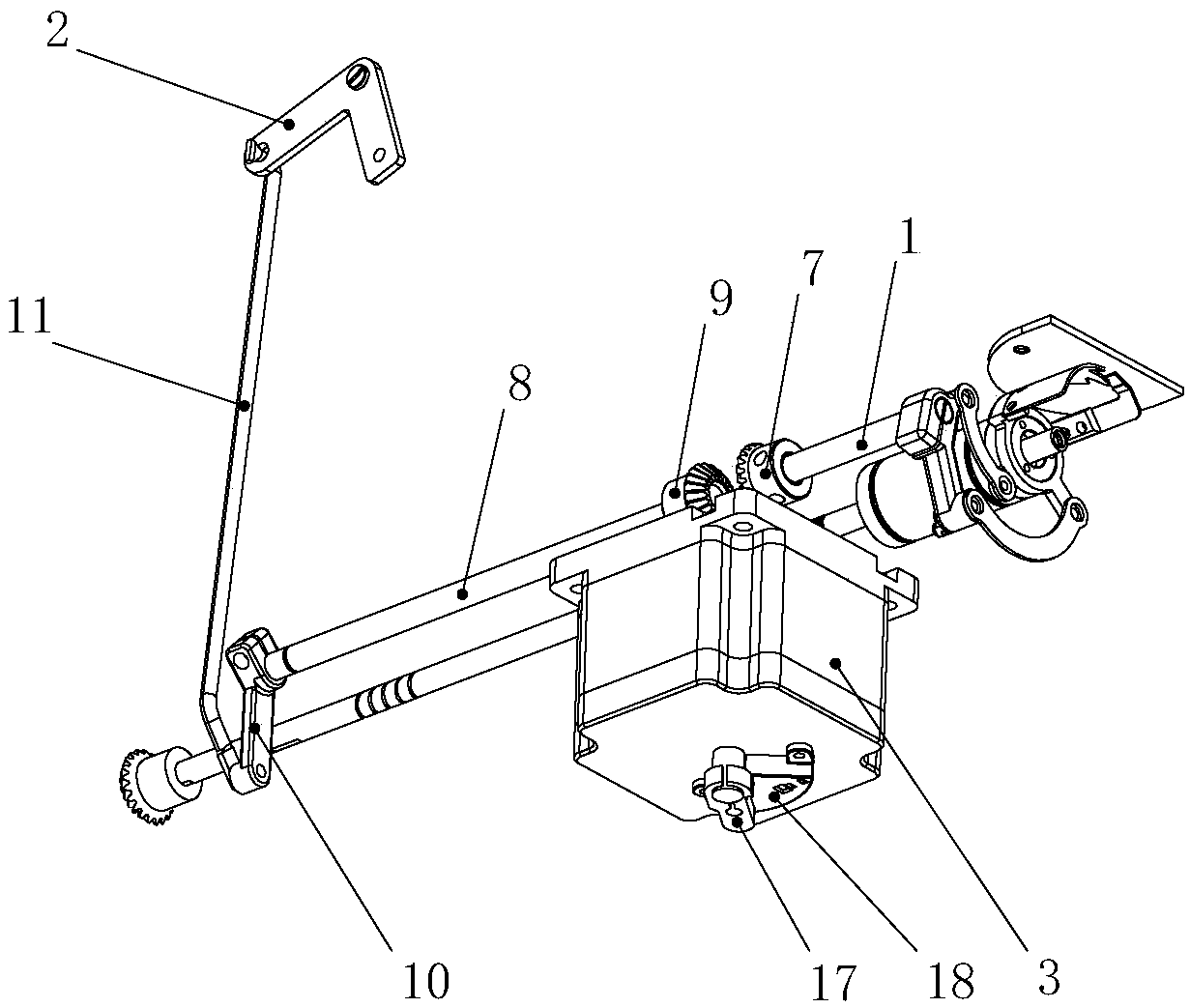

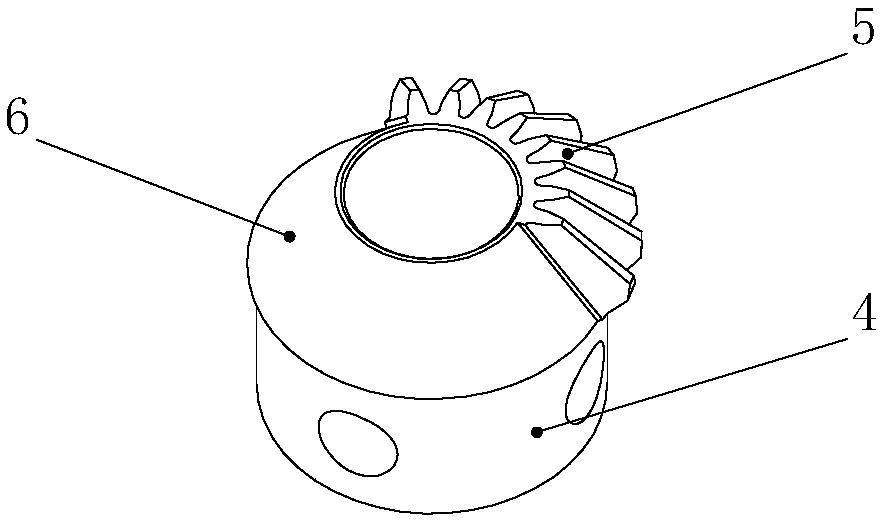

[0028] One of the objects of the present invention is to provide an automatic thread trimming and presser foot lifting mechanism for a sewing machine, which includes a thread trimming mechanism and a presser foot lifting mechanism arranged on the casing, and the thread trimming mechanism is rotatably connected to the casing One end of the thread trimming drive shaft 1 is connected, and the thread trimming drive shaft 1 is rotated to drive the thread trimming mechanism to perform the thread trimming action. The presser foot lifting mechanism is connected to one end of the presser foot rear lever 2 hinged on the casing. The presser foot rear lever 2 drives the presser foot lifting mechanism to perform the presser foot lifting action. The casing is provided with a driving motor 3, and the output shaft of the driving motor 3 is provided with a driving bevel gear 4, and a part of the driving bevel gear 4 The outer peripheral surface is provided with teeth 5, and another part of the ...

Embodiment 2

[0037] The structure of this embodiment is basically the same as that of Embodiment 1, the main difference is that: the transmission assembly includes a cam 12 arranged on the output shaft of the drive motor 3, and the protruding part of the cam 12 is in the same position as the smooth surface 6 of the drive bevel gear 4. Correspondingly, and the cam 12, the drive bevel gear 4 and the output shaft of the drive motor 3 rotate synchronously. The other end of the presser foot is against the corresponding end of the lever 2 after lifting the presser foot. During the thread trimming process, the drive motor 3 drives the thread trimming drive shaft 1 to rotate through the meshing of the teeth 5 of the driving bevel gear 4 with the thread trimming bevel gear 7, and one end of the push rod 13 abuts against the base circle of the cam 12; During the presser foot process, the driving motor 3 pushes the push rod 13 to move through the protruding part of the cam 12, and then drives the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com