Self-cleaning integrated pump station

A self-cleaning, pumping station technology, used in pumping stations, cleaning hollow objects, cleaning methods and utensils, etc., can solve problems such as inability to achieve efficient operation, no improvement in pump barrel design, etc. The effect of reducing the maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and specific embodiments:

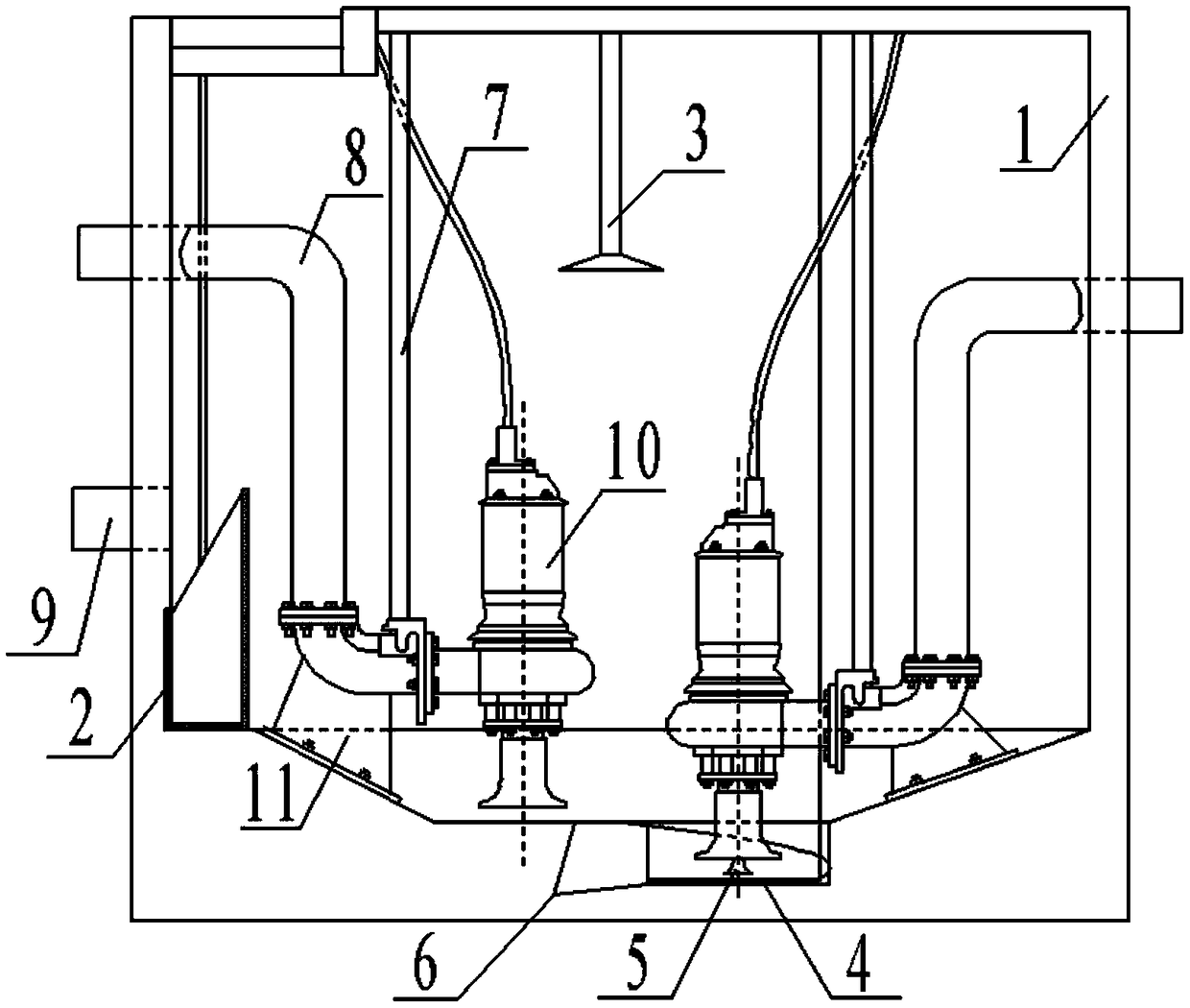

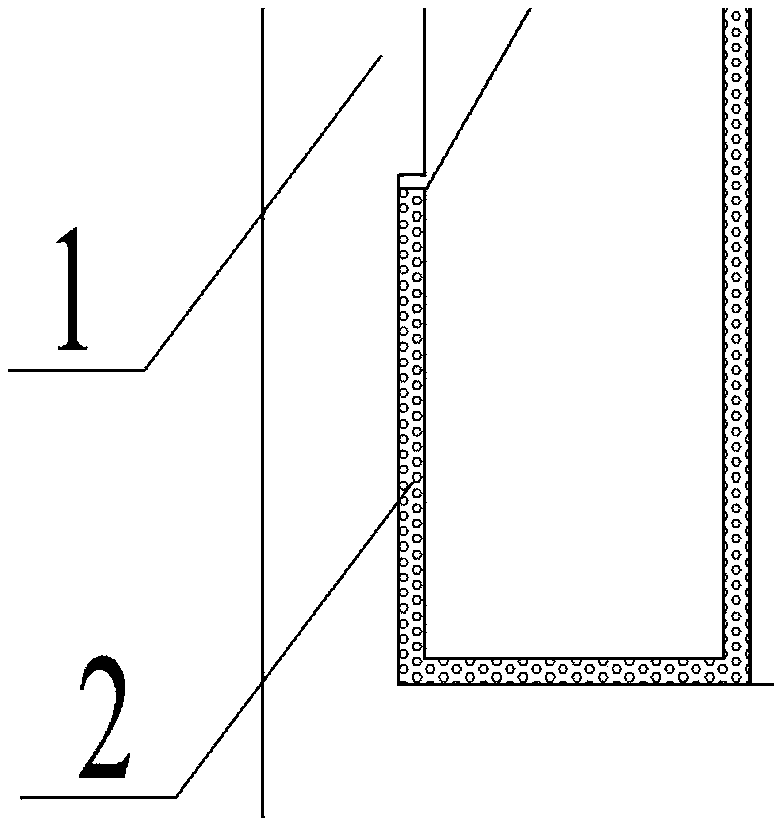

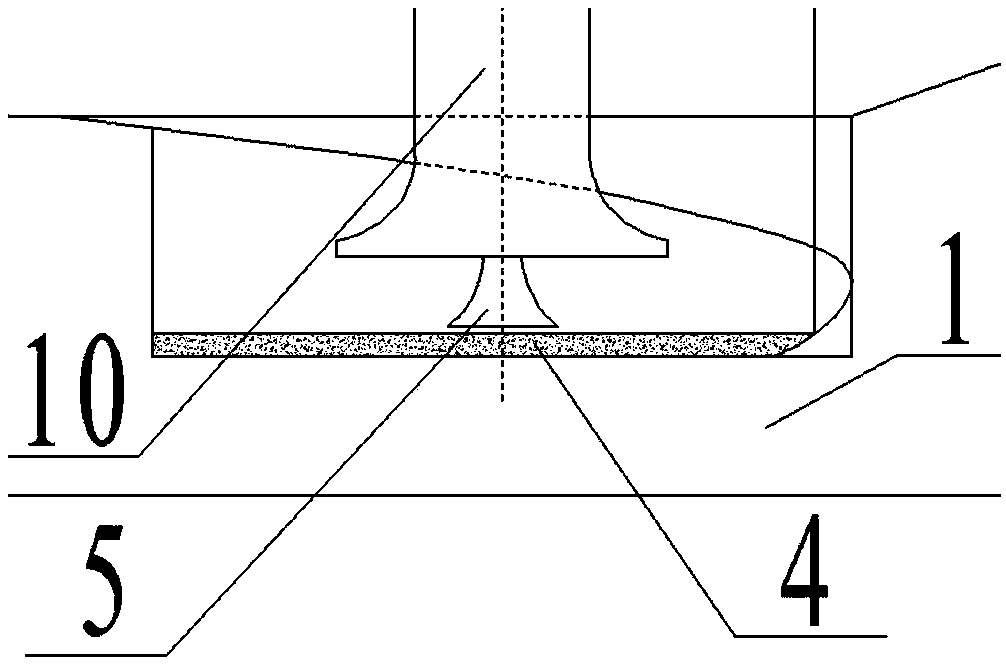

[0023] Such as figure 1 As shown, a structural embodiment of a self-cleaning integrated pump station of the present invention is given. A self-cleaning integrated pump station includes a pump barrel 1, a filter tank device 2, and a solid particle adsorption soft board device. 4. The horn tube integrated water guide cone 5, the bottom of the high and low stage cylinder 6, the guide rail 7, the water outlet pipe 8, the water inlet pipe 9, the pump device 10, the coupling base 11, wherein the pump barrel 1 is provided with a coupling base 11, The water outlet pipe (8) is fixedly connected with the coupling base 11, the guide rail 7 and the pump device (10) are connected with the coupling base 11 through the coupling device, and the inlet of the water inlet pipe 9 is provided with a filter tank device 2 which passes through the card The tank is attached to the pum...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap