Exploiting device and method for horizontal well of coalbed methane

A horizontal well and coalbed methane technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of cement slurry polluting coal seams, affecting coalbed methane mining, and not suitable for cementing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

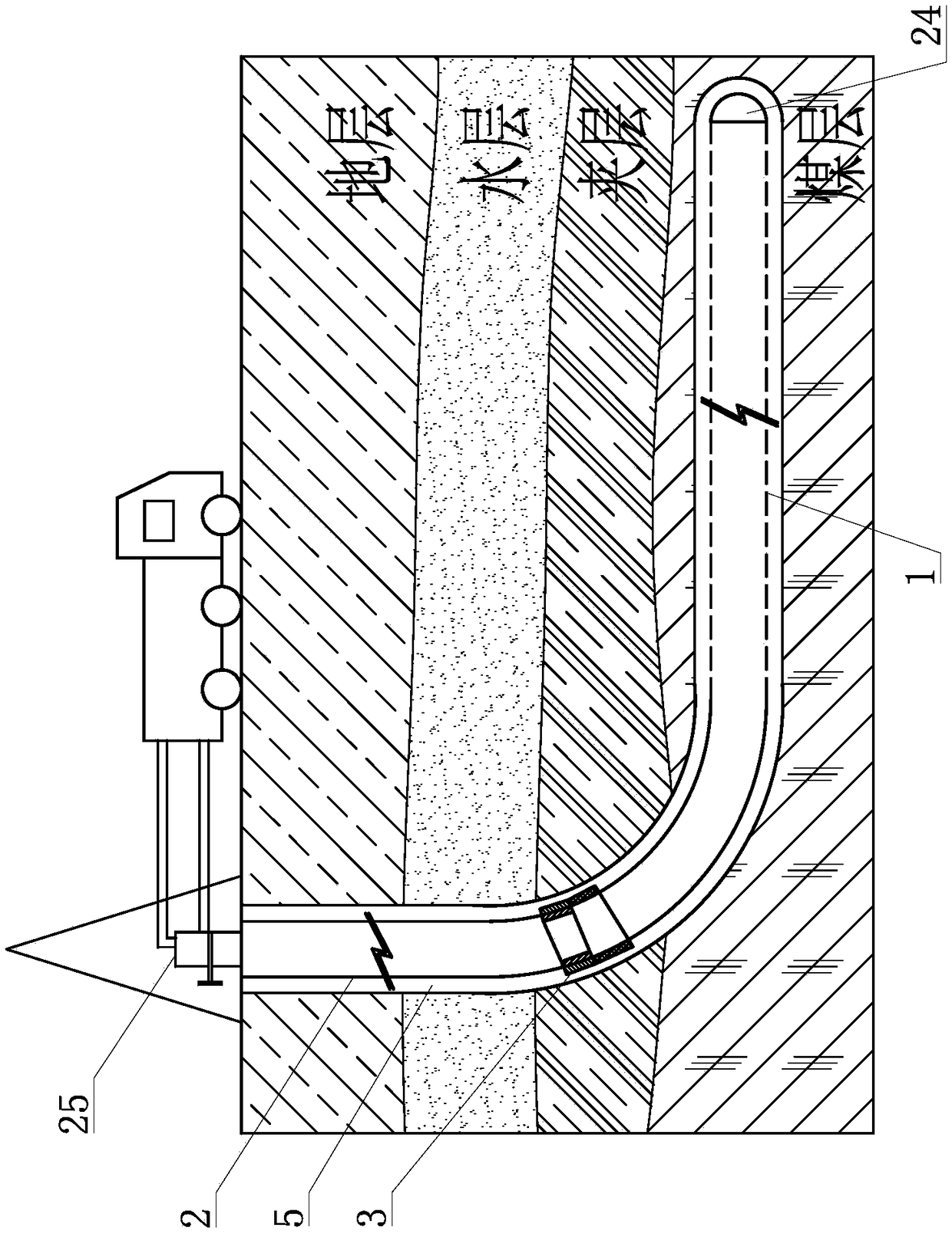

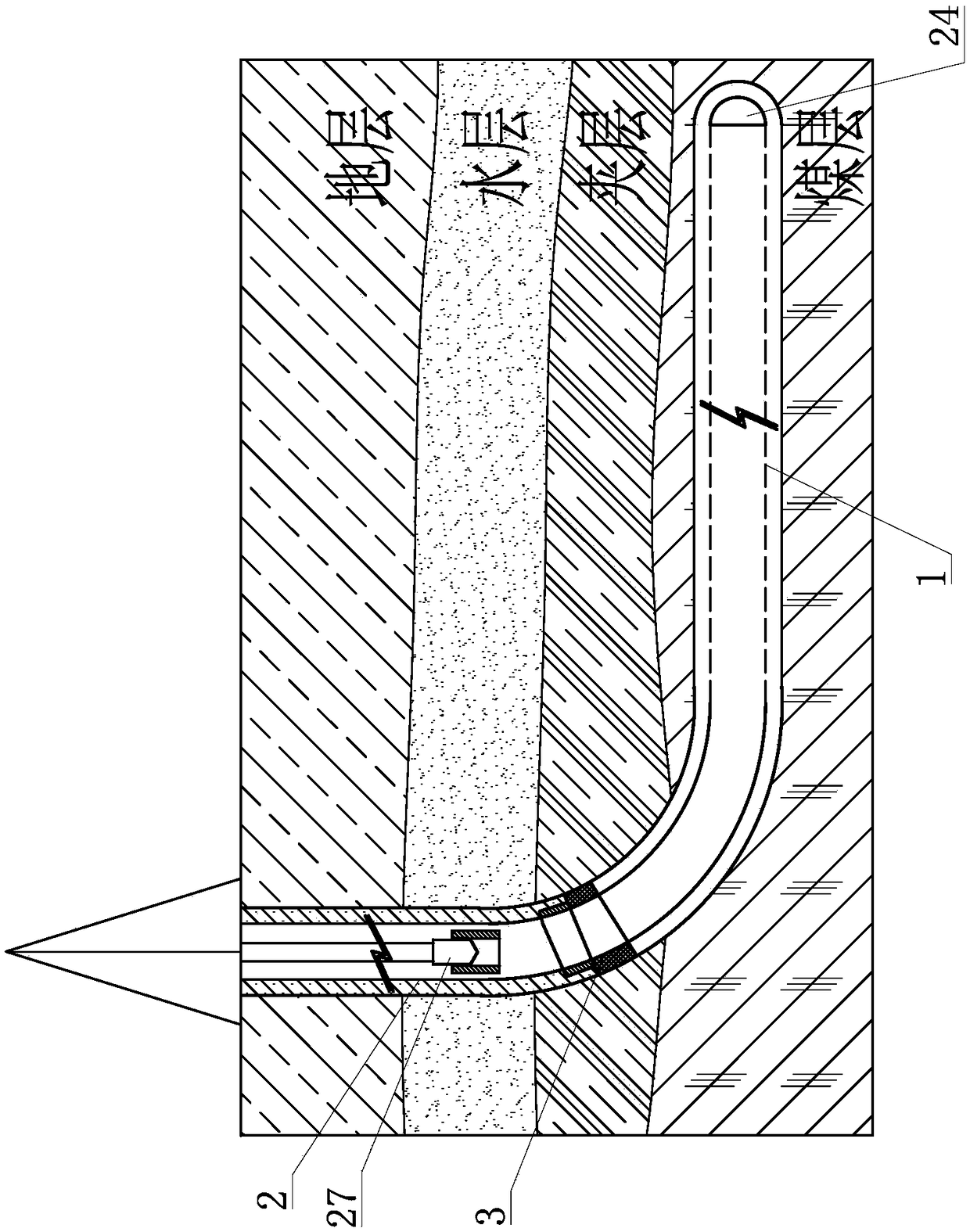

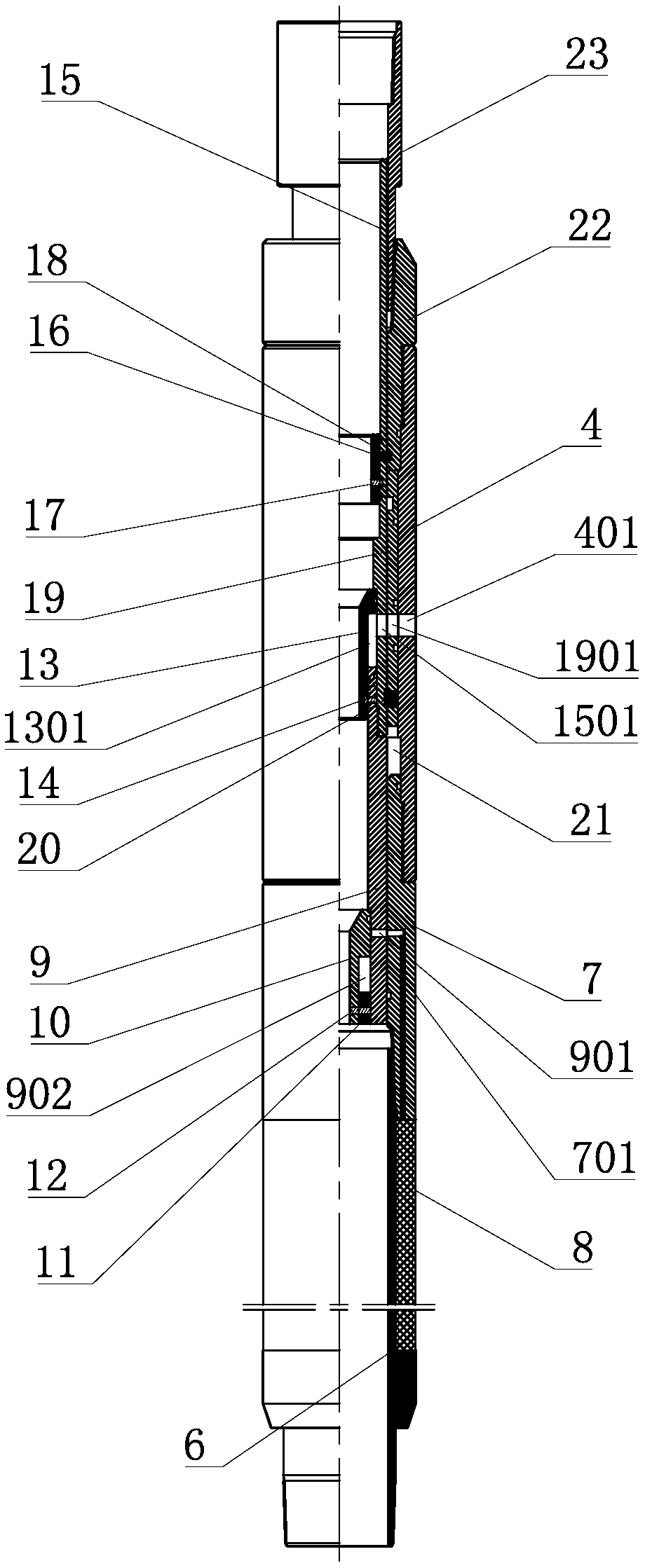

[0036] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0037] Such as Figure 1-5 Shown, a kind of exploitation device that is used for coalbed methane horizontal well, comprises:

[0038] A screen pipe 1, which is lowered into the horizontal well position of the coal seam;

[0039] Casing 2, the casing 2 is connected with the screen 1, run into the vertical well section;

[0040] A connection assembly 3, the connection assembly 3 connects the screen pipe 1 and casing 2, the connection assembly 3 includes an isolation device and salvageable internal accessories, the isolation device is connected to the casing 4, and the casing 4 Connected to casing 2 via connecting device;

[0041] The isolation device is used to abut against the well wall after expansion, and separate and block the interfering formation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com