A method for predict that condensing performance of a dish-type triangular element splice parabolic film condenser

A technology of performance prediction and triangular elements, which is applied in the direction of instruments, special data processing applications, complex mathematical operations, etc., can solve the problems of unclear physical meaning and inability to truly reflect the specific situation of triangular elements combined with paraboloids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] Ignoring the daily tracking error, the quasi-geodetic grid model accepts the prediction of surface energy flow density, assuming that the solar radiation energy flow density is 200w / m 2 , the position of the receiving surface is located at Z=F, Z=F+0.075, Z=F-0.075, predicting the energy flow density of different receiving surfaces, Figure 7 is a specific forecast map.

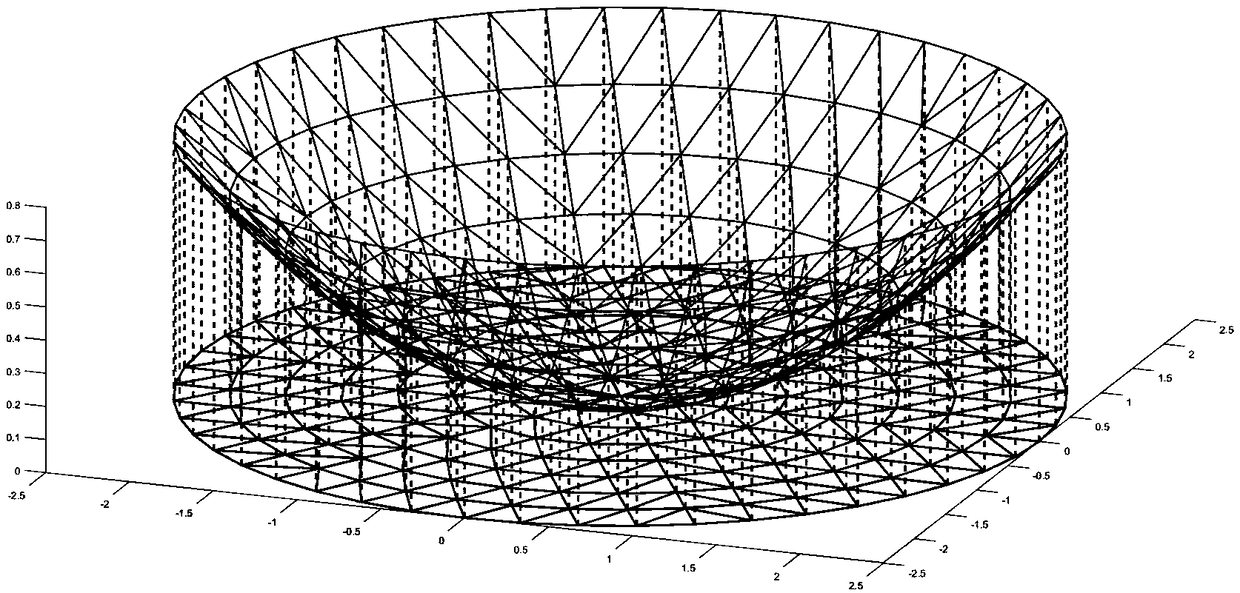

[0100] refer to figure 1 , the basic parameters of the concentrator are the aperture D=5m, the focal length F=2m, the number of sub-rings P=8, and the number of first torus slices TN=6

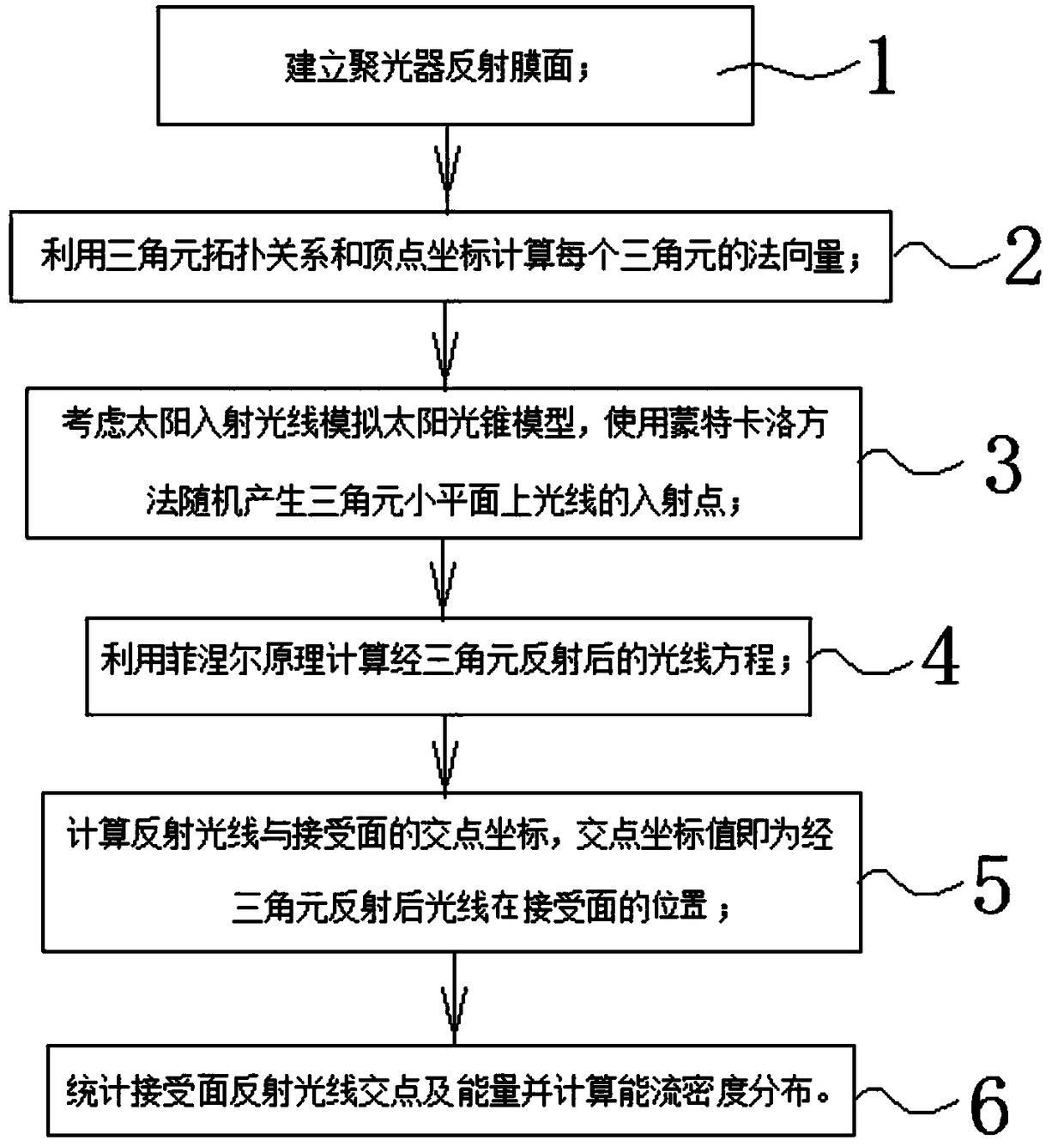

[0101] Step 1. Establish the reflective film surface of the quasi-geodesic grid concentrator

[0102] combine Figure 2a and Figure 2b , to establish the topological relationship between the quasi-geodesic mesh film surface and the triangular elements. The surface area of the condenser aperture is:

[0103]

[0104] In the formula, A is the area of the condenser aperture, and D is the diameter of the ref...

Embodiment 2

[0166] Ignoring the daily tracking error, the three-way grid merges the parabolic model, assuming that the solar radiation energy flow density is 200w / m 2 , the position of the accepting surface is at Z=F, Figure 8 is the specific prediction result graph.

[0167] The basic parameters of the concentrator are aperture D = 5m, focal length F = 2m, number of sub-rings P = 8, number of first torus slices TN = 6

[0168] Step 1. Establish the reflective film surface of the concentrator,

[0169] combine Figure 3a and Figure 3b , to establish the topological relationship between the three-way mesh film surface and the triangle elements. The three-way mesh divides the radius into P parts on the projection surface, but the triangles in the projection surface are equilateral triangles.

[0170] All the other steps are identical with embodiment 1

[0171] For specific applications, there are apparent solar tracking errors, quasi-geodetic grid models, and prediction of surface en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

| Focal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com