Roller type no-tillage seeding reversed T-shaped ditcher

A no-tillage sowing and drum-type technology, which is applied in the direction of sowing, planter parts, excavation/covering trenches, etc., can solve the problems of no-tillage sowing openers such as soil penetration, passability and poor seedbed conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail with reference to the drawings:

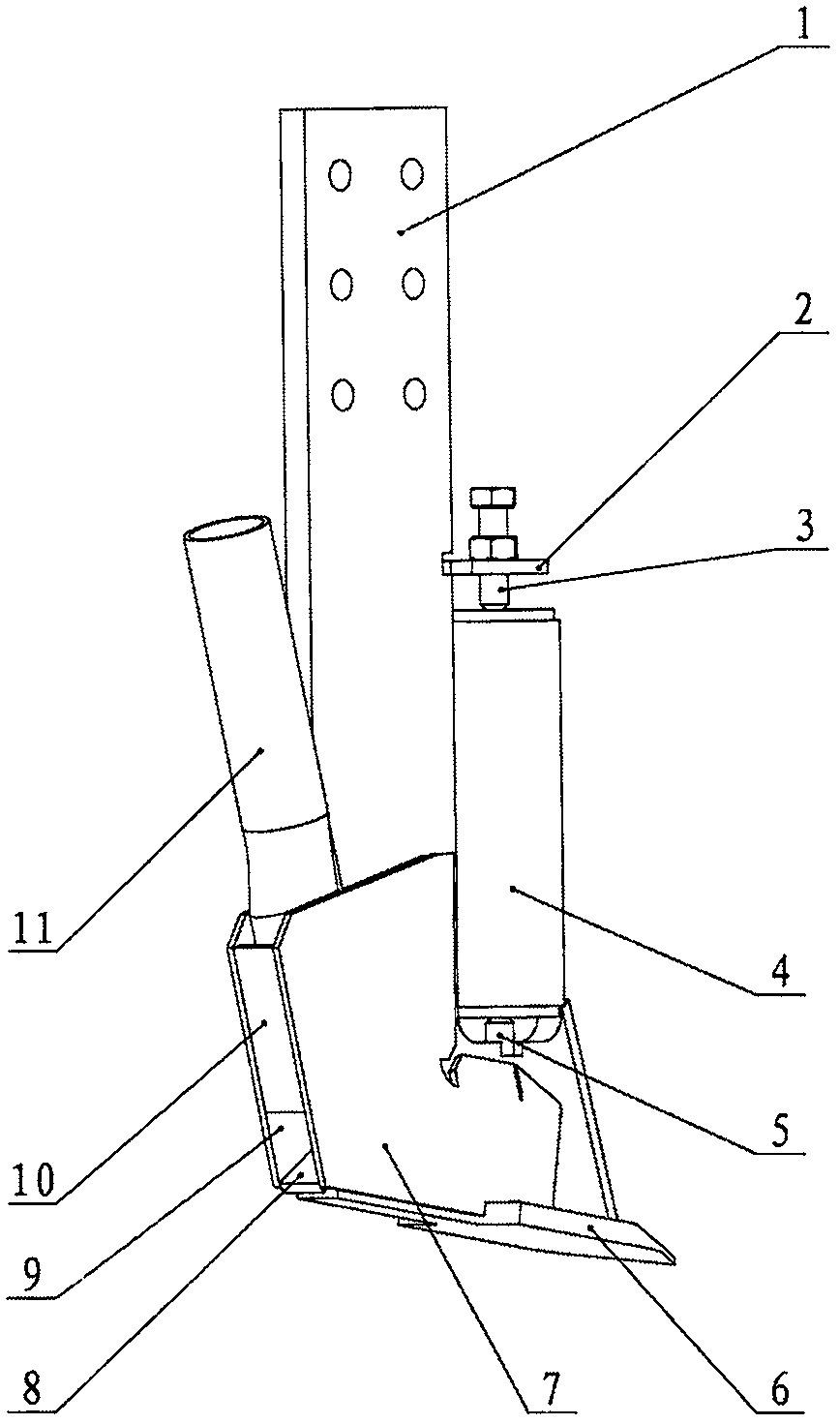

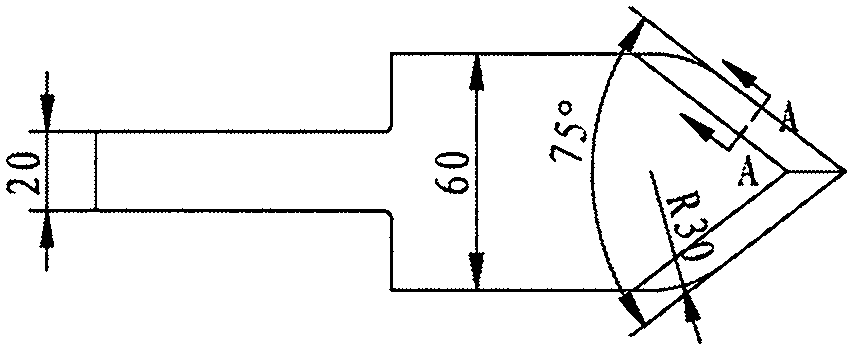

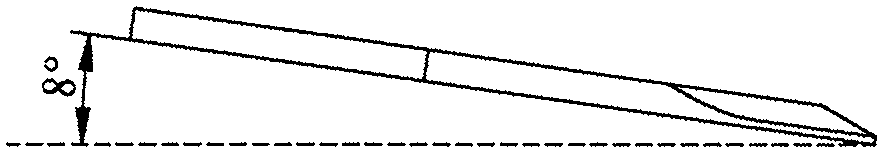

[0016] A roller-type no-tillage seeding inverted T-shaped opener, which is mainly composed of a vertical blade column (1), a roller frame plate (2), an upper center (3), a roller (4), a lower center (5), and soil Shovel (6), right wing plate (7), material guide plate (8), left wing plate (9), baffle plate (10), and seeding tube (11) are composed; a blade is provided in front of the sharp blade column (1) for To chop up the stubble and soil in the soil, the left wing plate (9) and the right wing plate (7) sandwich the upright column (1) and fix them together; the seeding pipe (11) is installed on the left wing plate (9) ) And the right wing plate (7) and fixed behind the upright post (1); the baffle plate (10) is fixed behind the left wing plate (9) and the right wing plate (7) and connected to the left wing plate (9) ) And the right wing plate (7) constitute a blanking space to prevent see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Edge angle | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com