A rice processing enzyme liquid sprayer

A technology of sprayer and enzyme solution, which is applied in grain processing, grain milling, agriculture, etc., can solve the problems of large quantity of brown rice, thick accumulation, and no specific instructions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

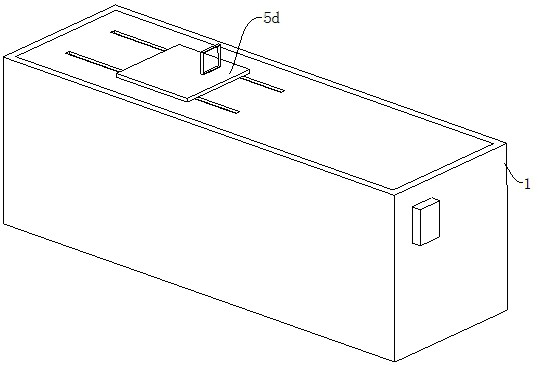

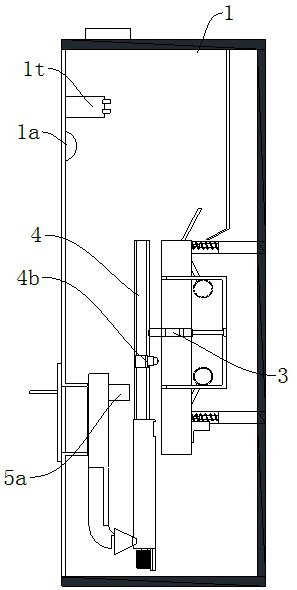

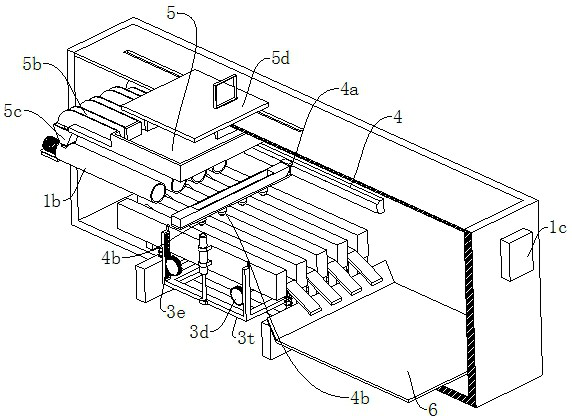

[0029] refer to Figure 1 to Figure 6 A rice processing enzyme liquid sprayer shown includes a constant temperature bin 1, a temperature detector 1a, a jumping feeding mechanism and a spraying mechanism, and the upper part of the constant temperature bin 1 is provided with at least three equidistantly distributed along a straight line sequence. The small screw feeder 1b, the jumping feeding mechanism includes a jumping power unit and three feeding boards 2, each feeding board 2 is horizontal and is respectively arranged below the discharge end of a small screw feeding device 1b The jumping power device is located under all the feeding boards 2 and is connected to the bottom of all feeding boards 2. The jumping power device is used to drive all the feeding boards 2 to move up and down synchronously. The temperature d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com