An elevator for heavy workpiece transportation

A lifter and workpiece technology, applied in the field of lifters, can solve the problem of not being able to meet the transportation needs of ultra-long and overweight workpieces, and achieve the effects of compact structure, high transmission efficiency and large bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

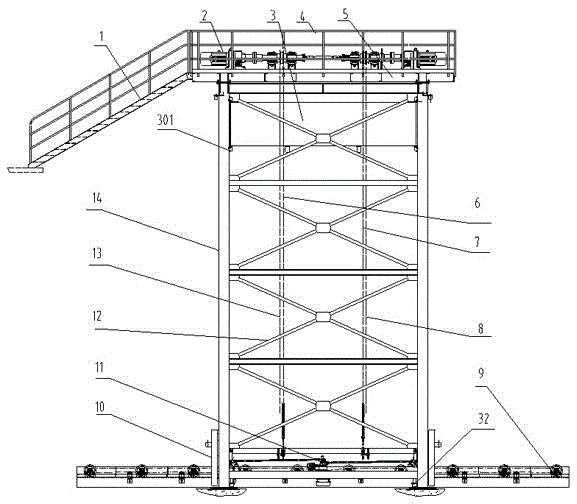

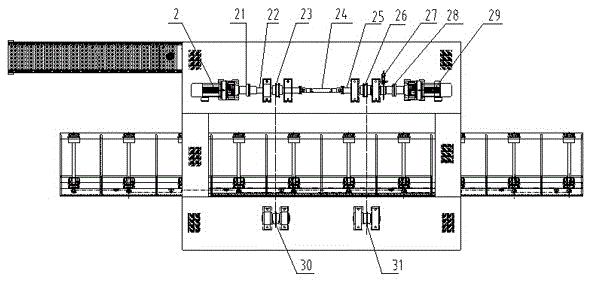

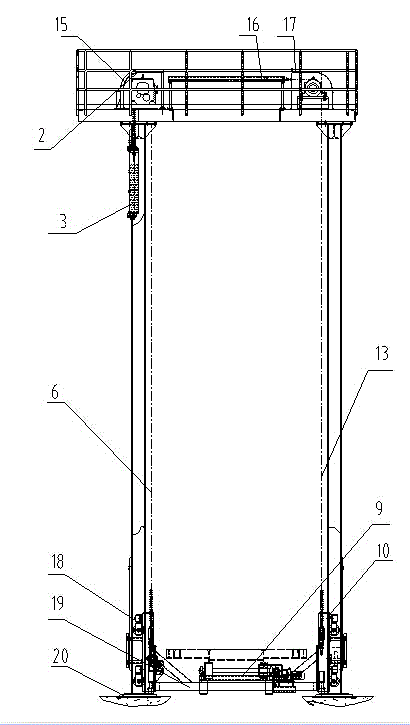

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] As shown in the figure, a lift for heavy workpiece transportation is provided with a frame 12. The frame 2 is composed of a column frame and a driving maintenance platform arranged on the column frame. The driving maintenance platform adopts a combined assembly type: It is split into a driving platform, a driven platform, and two connecting platforms, a total of four platforms. The two connecting platforms connect the driving platform and the driven platform with connecting bolts. This structure is convenient for loading and transportation. Maintenance and repair, but also greatly reduce the risk factor in the process of installation and lifting.

[0030] The column frame is connected together by four columns arranged in a rectangular shape through four frame girders arranged at the top of the column, and the column 14 is made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com