Casting process and mold for complex aluminum alloy shell of aero-engine

An aero-engine and casting technology, which is applied in the field of aluminum alloy casting, can solve problems such as restricting the development progress of new research products, high casting and molding technology, and restricting the performance of aero-engine fuel control systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

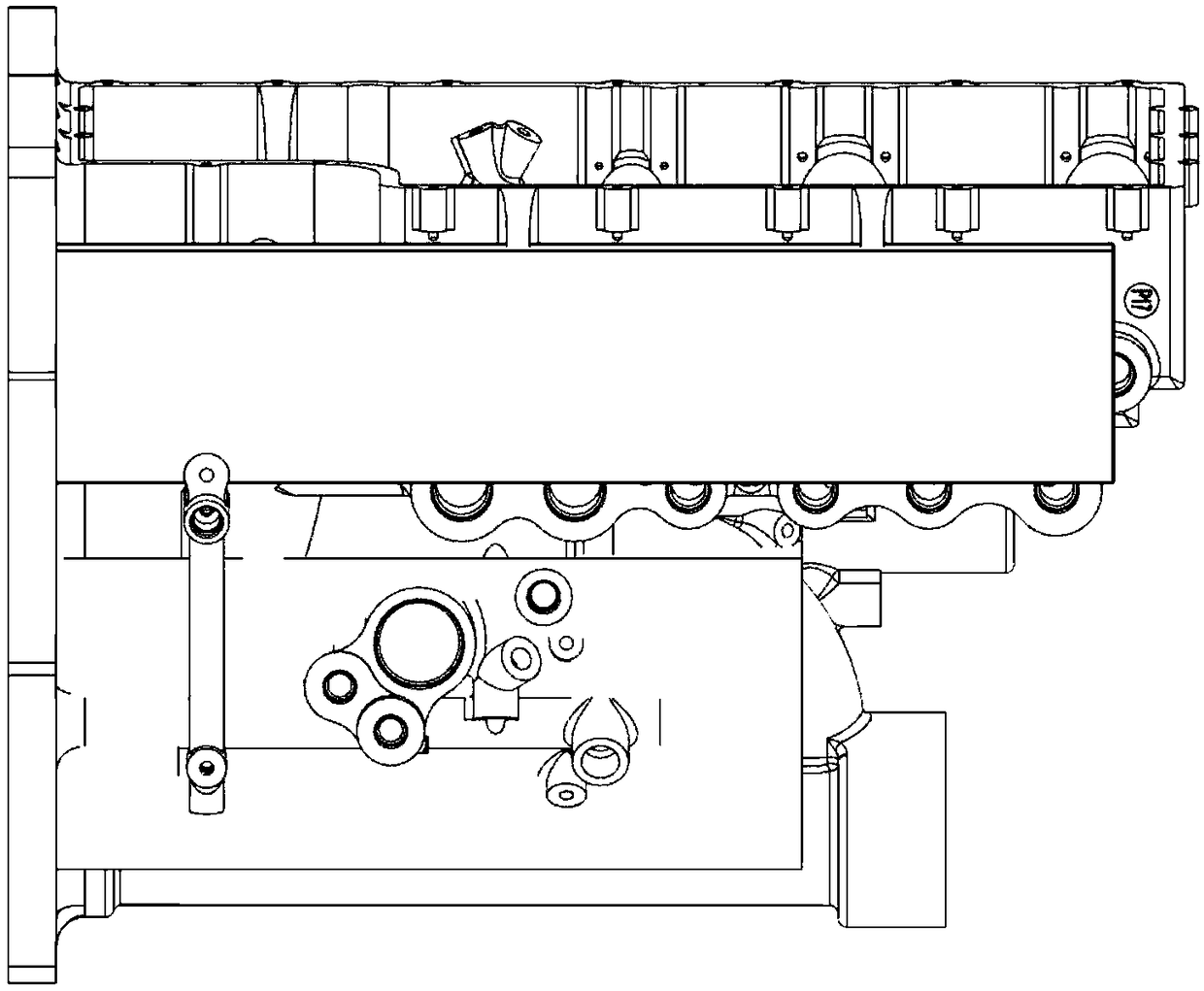

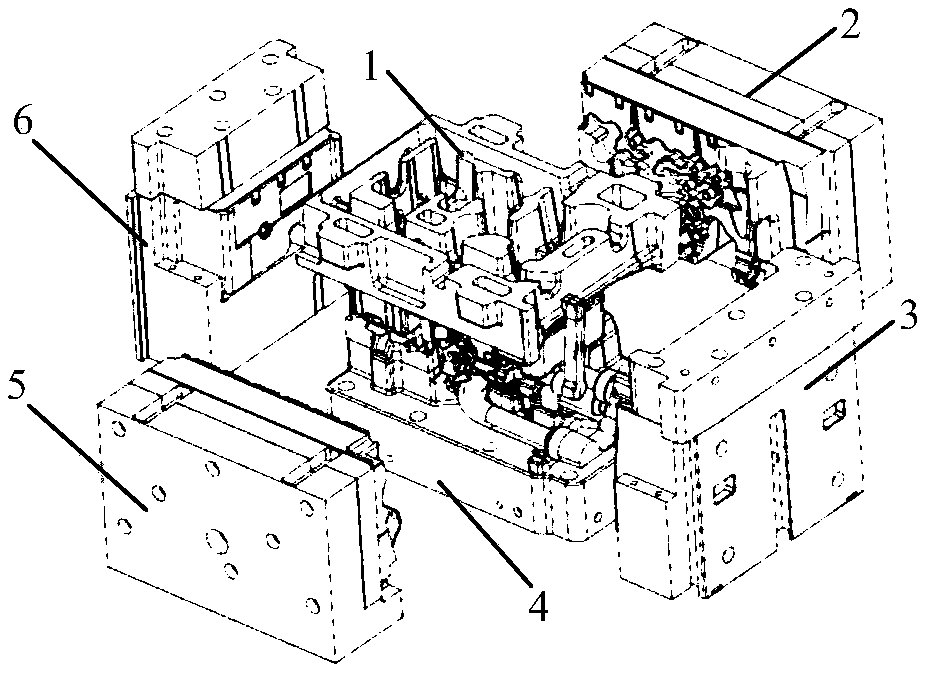

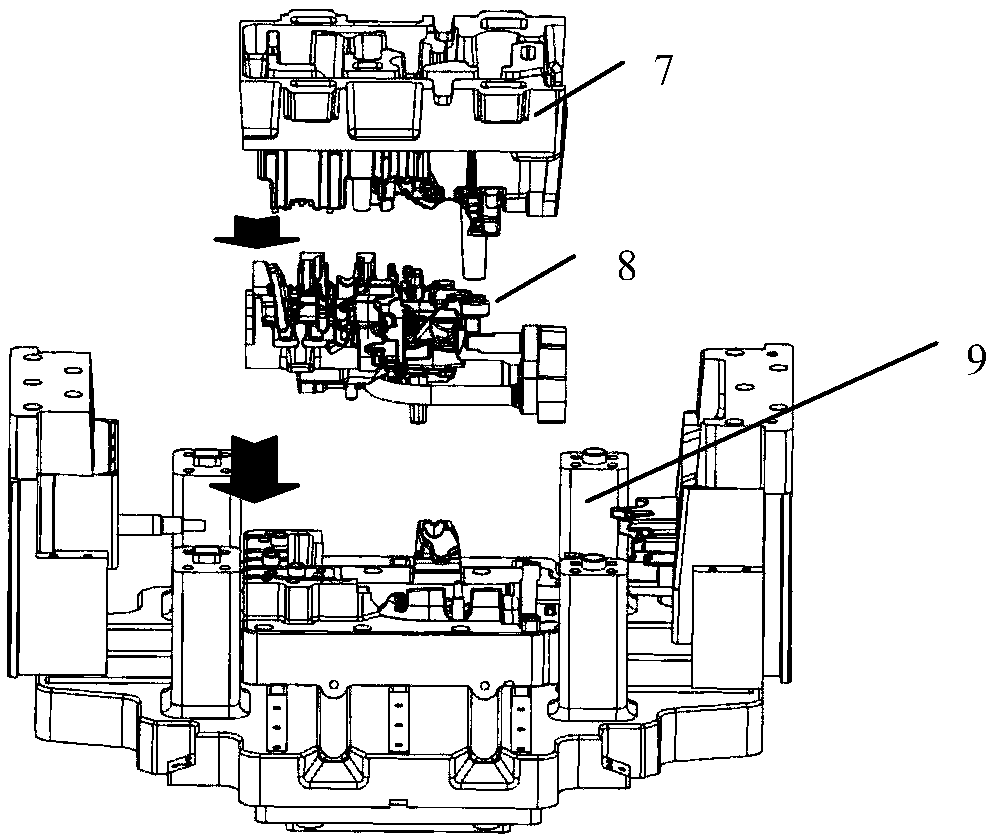

[0037] The invention provides a casting process for a complex aluminum alloy shell of an aero-engine. The casting process for a complex aluminum alloy shell of an aero-engine comprises the following steps:

[0038] 1) Analyze the structure of the complex aluminum alloy shell to be cast to determine whether there is a mixed shell in the complex aluminum alloy shell to be cast, and if so, proceed to step 2); if not, exit directly; the mixed shell is unsealed The top-to-bottom superposition of shells that require high density and compactness requires shells;

[0039] 2) For shells without airtightness requirements, use sand casting process to form sand molds; for shells with compactness requirements, use metal mold casting process to form metal molds; wherein, the specific implementation method of sand molds is:

[0040] a1) The mold has no sealing requirements. The shell adopts the sand casting process to form a sand mold; the sand mold includes sand molds and sand cores that ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com