A composite treatment process of laser additive repair and surface nitriding of titanium alloy

A laser additive and composite processing technology, used in metal material coating technology, additive processing, metal processing equipment, etc., can solve problems such as high cost, pores and cracks, and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

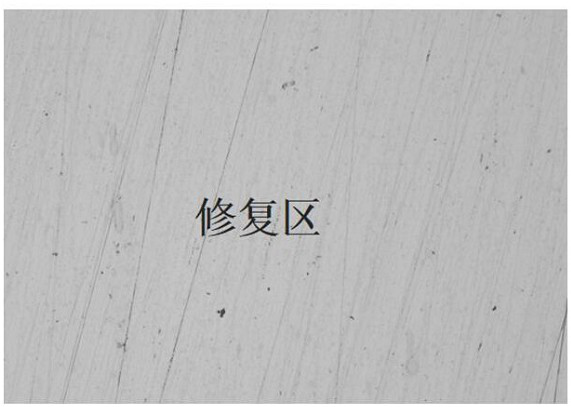

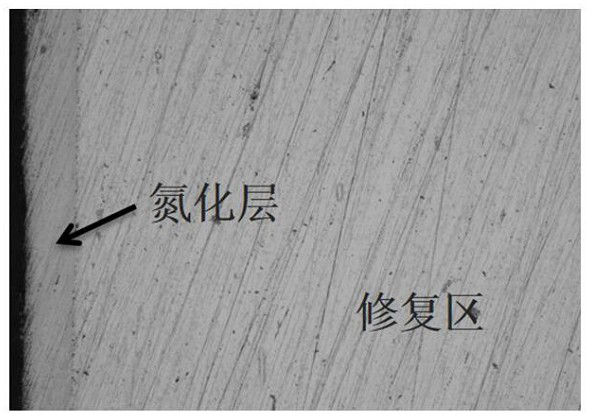

Embodiment 1

[0020] Take TC4 (α+β duplex) alloy as an example.

[0021] Step 1: Perform pretreatment on the surface of TC4 alloy parts, including machining, cleaning, sandblasting and drying of the area to be repaired; Step 2: Use a thermal imager to monitor the molten pool during the laser additive manufacturing process to obtain the shape of the molten pool appearance and temperature change information, calculate the average value a of the long axis of the molten pool and the average value b of the short axis, and calculate the average cooling rate ξ of the boundary of the molten pool; Step 3: According to 1.5≤a / b≤2.2, and 7.0×10 3 ℃ / s≤ξ≤8.3×10 4 The process parameters are optimized based on the ℃ / s principle to obtain the optimized additive repair process window: the laser power is 1350W, the scanning speed is 13mm / s, the spot diameter is 3.8mm, the powder feeding amount is 26g / min, and the overlapping amount is 50% , the height direction increment Z is 0.3 mm / layer, the repair materia...

Embodiment 2

[0025] Take TB1 (β type) alloy as an example.

[0026] Step 1: Perform pretreatment on the surface of TB1 titanium alloy parts, including machining, cleaning, sandblasting and drying of the area to be repaired; Step 2: Use a thermal imager to monitor the molten pool during the laser additive manufacturing process to obtain the molten pool Shape and temperature change information, calculate the average value a of the long axis of the molten pool and the average value b of the short axis, and calculate the average cooling rate ξ of the molten pool boundary; Step 3: According to 1.5≤a / b≤2.2, and 7.0× 10 3 ℃ / s≤ξ≤8.3×10 4 The ℃ / s principle optimizes the process parameters to obtain the optimized additive repair process window: the laser power is 1450W, the scanning speed is 13mm / s, the spot diameter is 3.5mm, the powder feeding amount is 27g / min, and the overlapping amount is 50% , the height direction increment Z is 0.3 mm / layer, and the repair material is a mixed powder of TB1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com