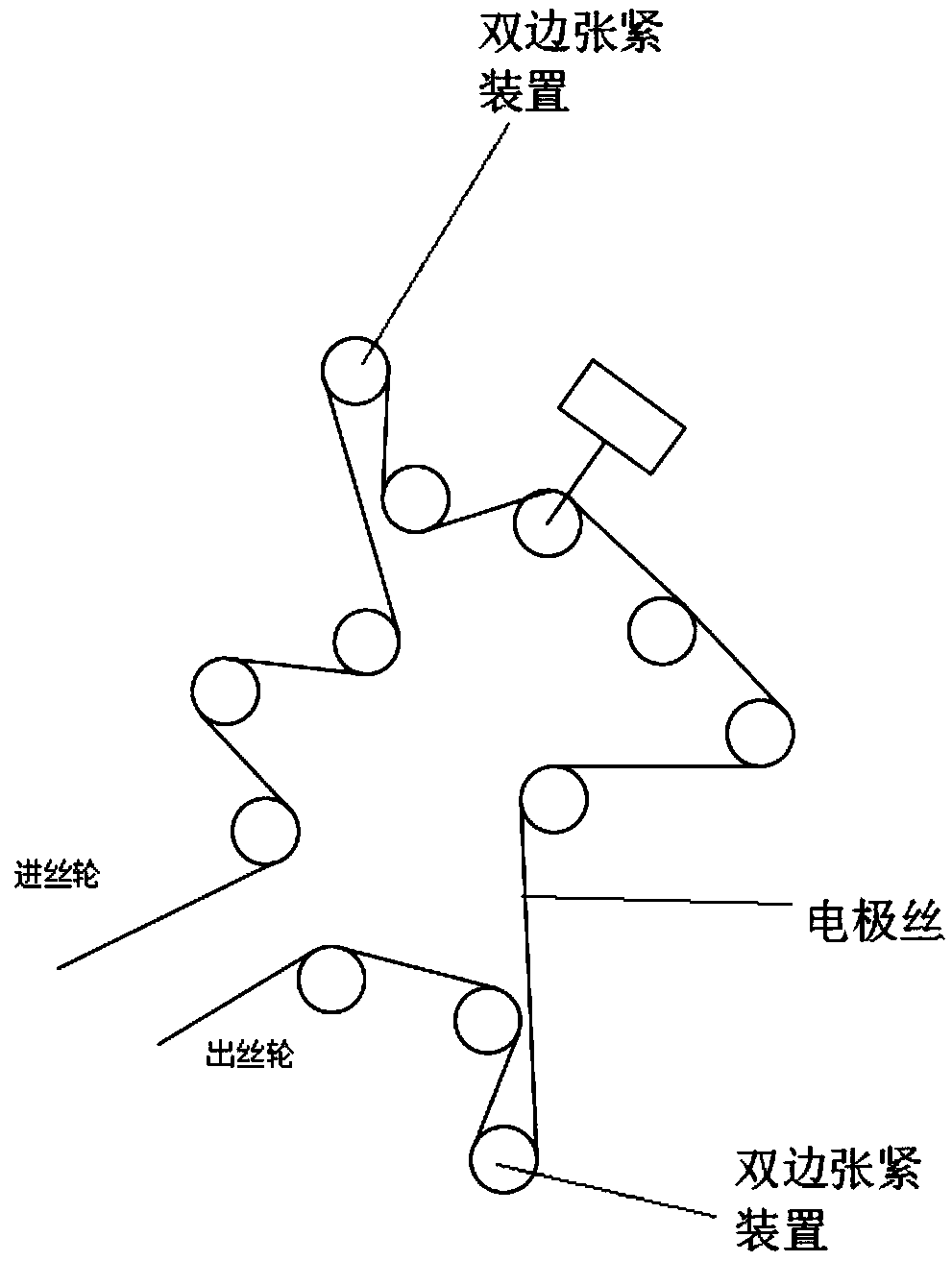

Bilateral tensioning device for wire electrode of synchronous wire-cut electric discharge machine tool

A technology of cutting processing and electric discharge wire, which is applied in the direction of electric processing equipment, electrode manufacturing, metal processing equipment, etc., can solve the problems of electrode wire relaxation, breakage, safety issues, etc., and achieve the goal of ensuring stability and preventing breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

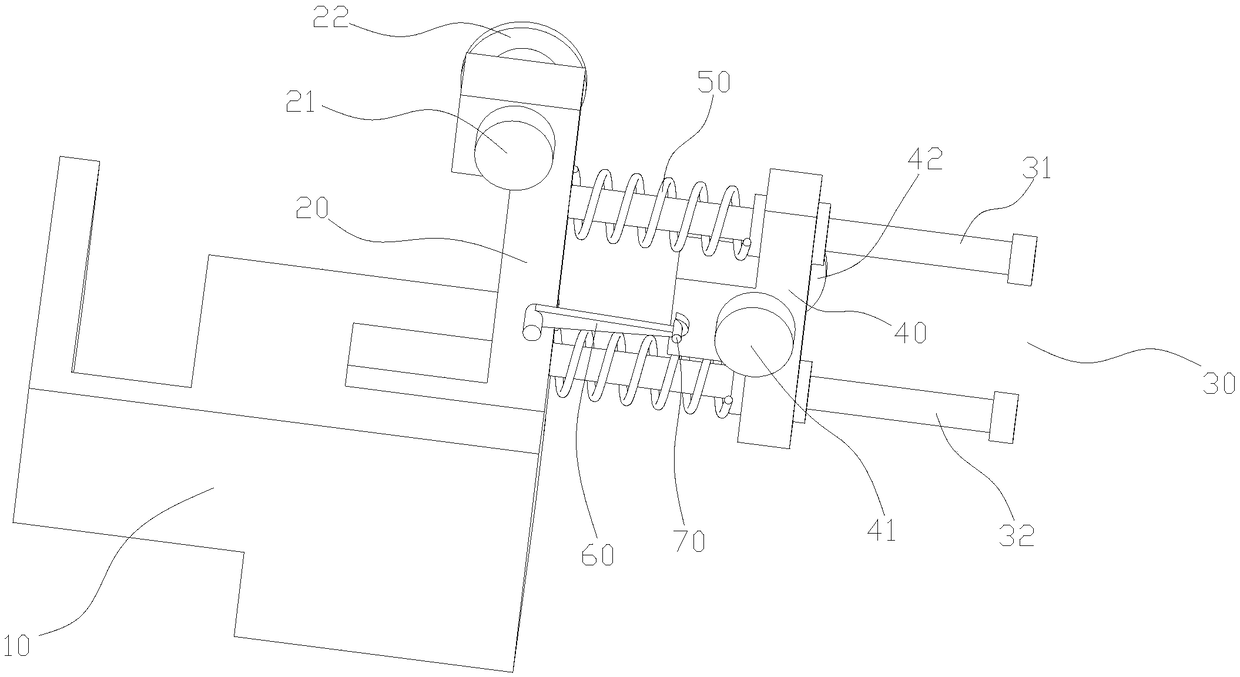

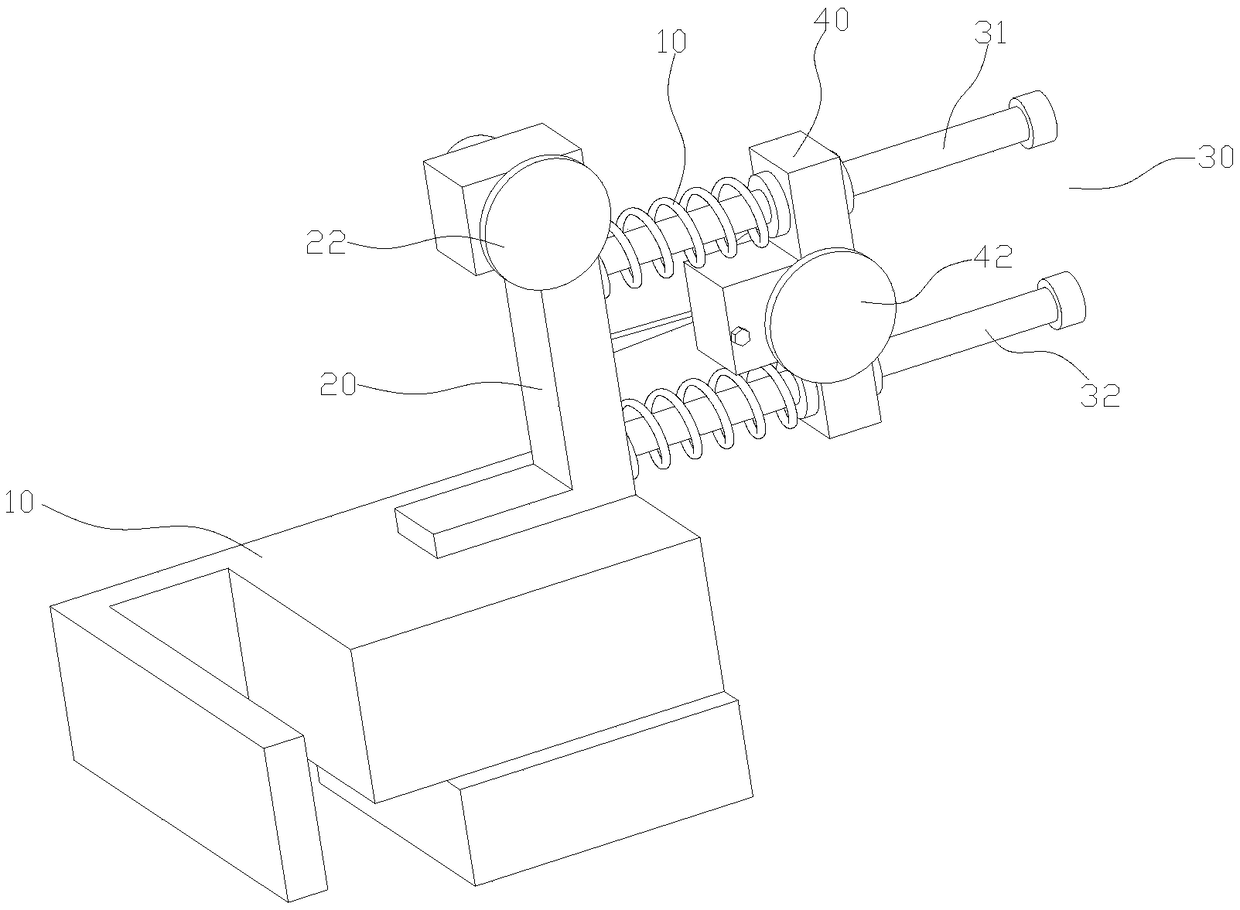

[0019] Please refer to figure 1 and figure 2 , a bilateral tensioning device for synchronous electric discharge machine tool wire electrode, comprising a base 10 and a vertical support 20, the vertical support 20 is fixed on the base 10, and the upper end of the vertical support 20 is fixed with a horizontal The upper fixed shaft 21, one end of the upper fixed shaft 21 is provided with an upper guide wheel 22;

[0020] One side of the vertical support 20 is provided with a guide rod 30 arranged horizontally below the upper fixed shaft 21, and the upper fixed shaft 21 and the guide rod 30 are perpendicular to each other, and the guide rod 30 is provided with a guide rod 30 that can slide along the guide rod 30. The slider 40, and the guide rod 30 is provided with a return spring 50 between one side of the vertical bracket 20 and the slider 40, one end of the back spring 50 is in contact with one side of the vertical bracket 20, and the other end is in contact with the slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com