Capsule medicine bubble cap forming device

A molding device and medicine technology, which is applied to household components, household appliances, and other household appliances, can solve the problems of poor molding effect, unqualified blisters, and low molding rate, so as to reduce energy consumption, reduce scrap rate, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

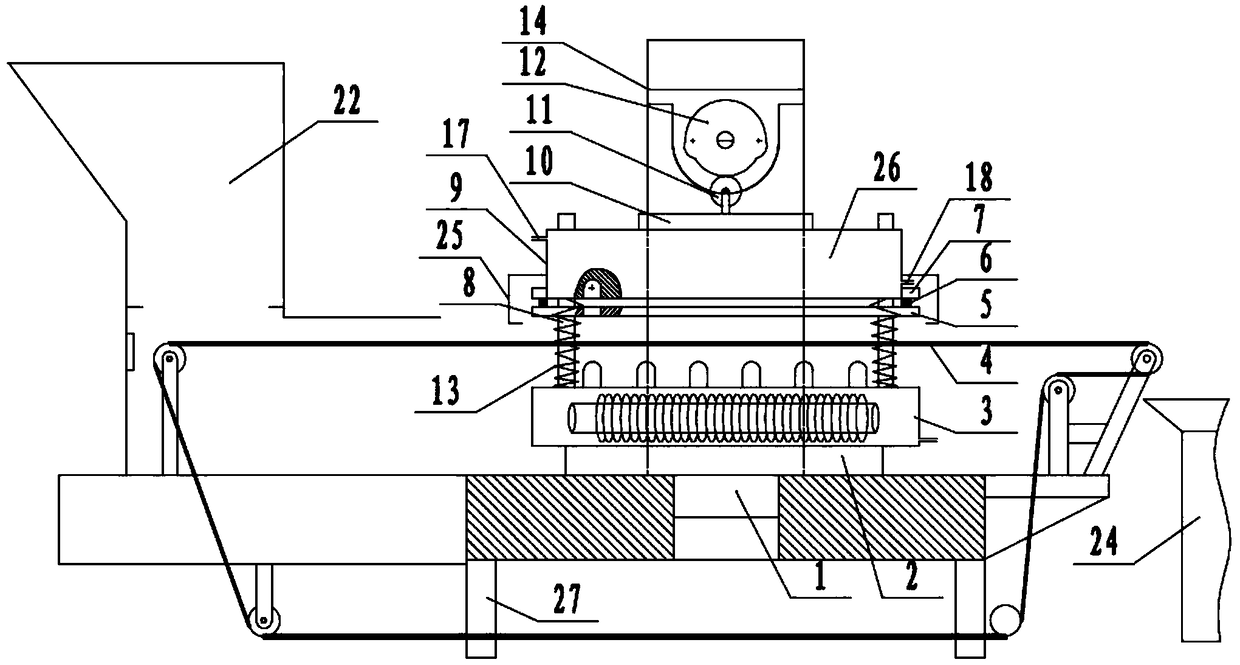

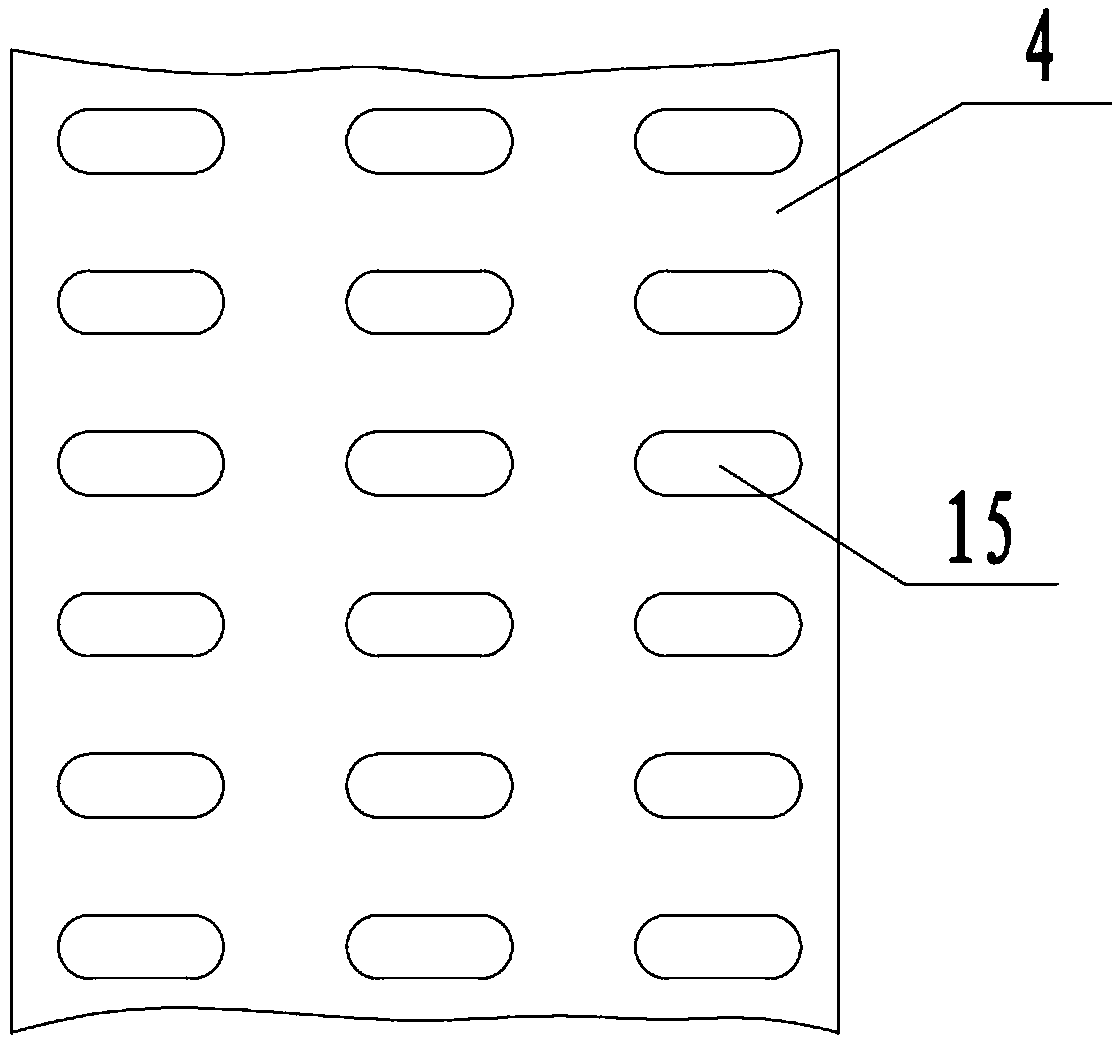

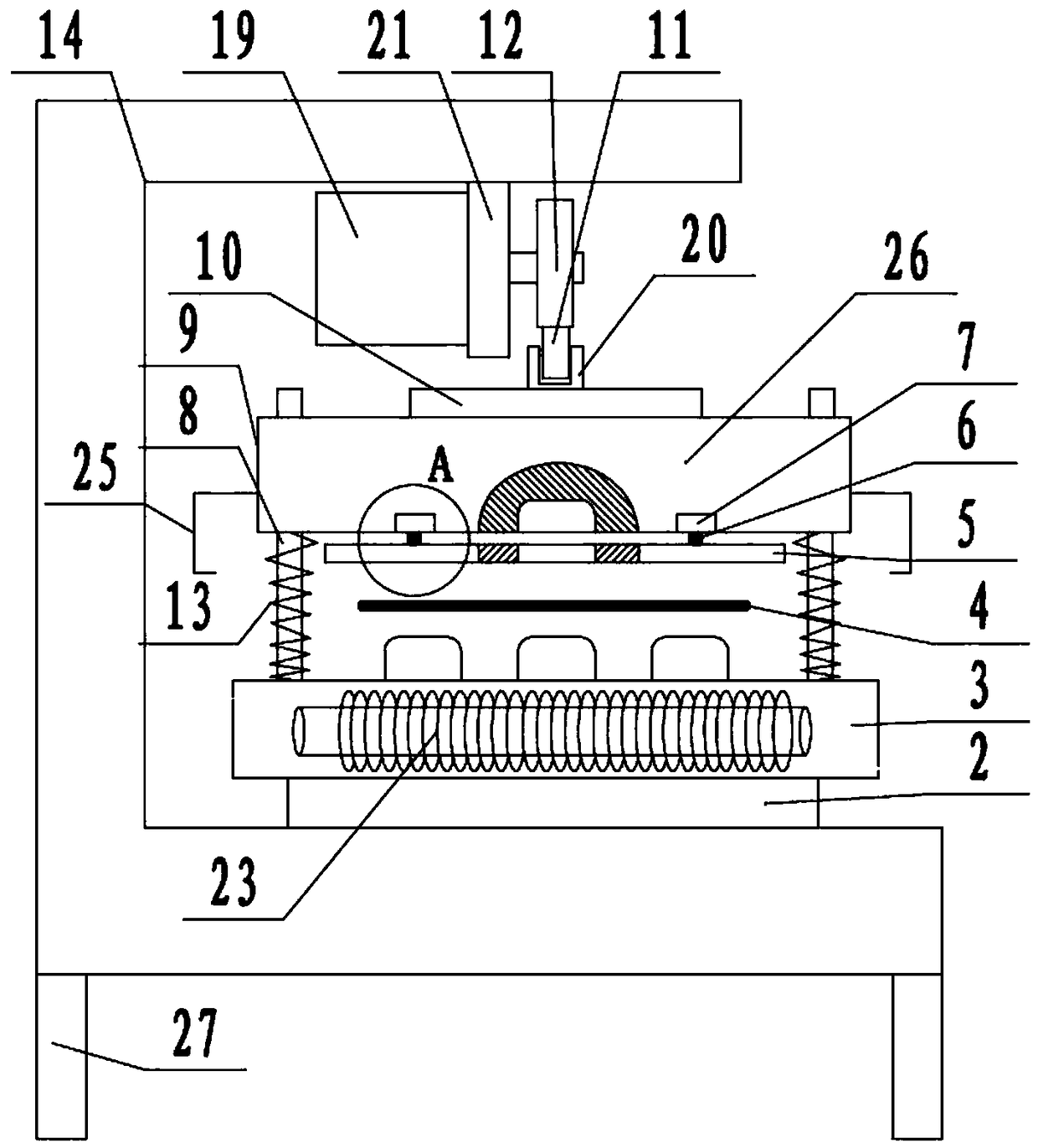

[0021] Embodiment 1: as Figure 1-Figure 4 As shown, a capsule drug blister forming device includes a feed hopper 22, a punch 3, a die 9, a thin conveyor belt 4 and a finished product collection hopper 24, the punch 3 is fixedly connected to the punch seat 2, and the punch The base 2 is fixedly connected to the bottom column 1, the die 9 is fixedly connected to the die base 10, the die 9 is movably connected to the guide rod 8, the guide rod 8 is fixedly connected to the punch 3, and the upper side of the die base 10 A drive mechanism to drive its movement is installed, the drive mechanism and the floor column 1 are installed on the bracket 14, a thin conveyor belt 4 is installed between the punch 3 and the die 9, the thin conveyor belt 4 is provided with a forming through hole 15, and the bracket 14 is Horizontal U-shaped structure, the guide rod 8 is sleeved with a return spring 13, and the two ends of the return spring 13 respectively abut on the punch 3 and the die 9, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com